Coal bed gas-liquid CO2 and active water collaborative fracturing technique method

A water fracturing and active water technology, applied in the field of reservoir stimulation and fracturing of unconventional reservoirs, can solve the difficulty of proppant carrying and placement, the complex fracture network of rock breaking efficiency, and the poor effect of reservoir stimulation. and other problems, to achieve the effect of better transformation effect, good seam-making effect and wide range of action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with examples.

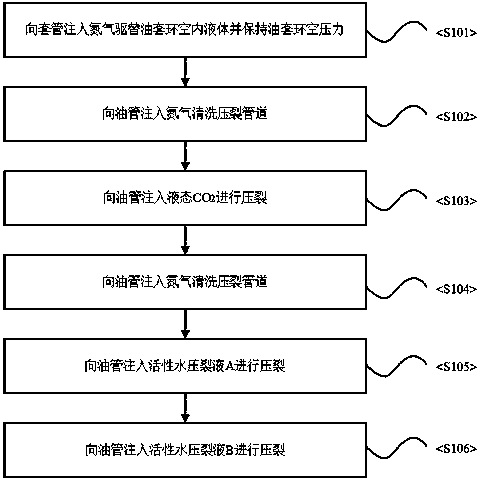

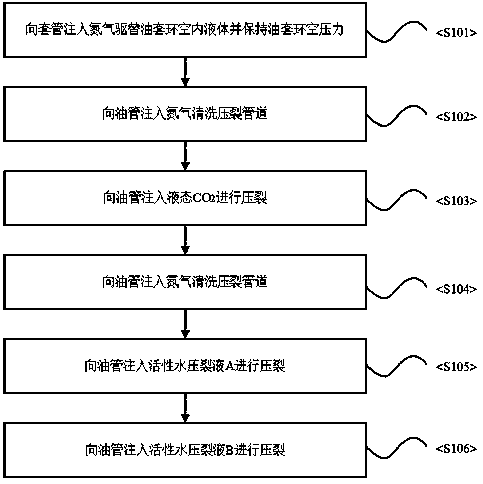

[0030] figure 1 A kind of coal bed gas liquid CO of the present invention 2 Flowchart of the co-fracturing process with active water. Such as figure 1 Shown, the inventive method comprises the steps:

[0031] Step S101: Inject nitrogen gas into the casing to displace the liquid in the oil-cassette annulus and maintain the pressure in the oil-cassette annulus.

[0032] Open the reverse circulation valve of the packer first, inject nitrogen gas into the casing, reverse circulation replaces the annulus liquid in the oil sleeve, and close the circulation valve of the packer after the displacement is completed.

[0033] Among them, the liquid in the oil jacket annulus is not resistant to low temperature, and the subsequent injection of liquid CO 2 Sometimes it will solidify and freeze, resulting in a decrease in the external pressure of the oil pipe, causing the risk of damage to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com