Metal roof panel whipstitching method

A metal house and panel lock technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of not being very strong and unable to resist wind, and achieve good and easy locking seams The effect of controlling and preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

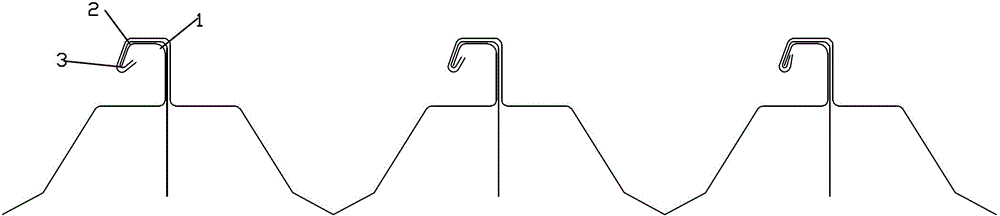

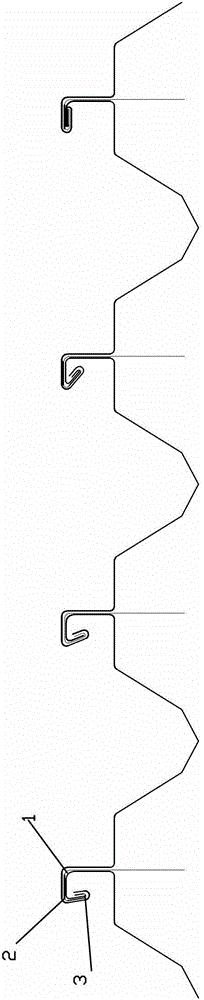

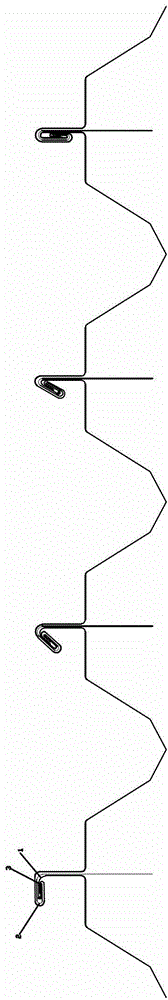

[0028] Such as Figure 1-Figure 3 As shown, a metal roof panel lock seam method comprises the following steps:

[0029] (1) Set the 90° angle of the metal roof panel to be locked as the first angle 1; bend the lateral side of the first angle 1 inward to form an angle of 110° and set it as the second angle 2; set the second angle 2 The longitudinal edge of the second angle 2 is bent inwardly to form an angle of 30° to position the third angle 3, and the third angle 3 is continuously bent inwardly through two processes. The first process bends the third angle 3 to 20°, and the second process bends the third angle 3 to the inside. The angle bent in the first process is then bent to 0° to obtain the third angle 3 of 0°; this step (1) is completed on the lockstitch folding machine invented by our company.

[0030] (2) Continue to bend the second angle 2 of the part to be seamed obtained in step (1) through four processes, the first process bends to 86°, and the second process bend...

Embodiment 2

[0034] Such as Figure 1-Figure 3 As shown, a metal roof panel lock seam method comprises the following steps:

[0035] (1) Set the 90° angle of the metal roof panel to be locked as the first angle 1; bend the lateral side of the first angle 1 to the inside to form an angle of 110° and set it as the second angle 2; the second The longitudinal side of the corner 2 is bent inward through three bending processes to form the third corner 3, and the longitudinal side of the second corner 2 is bent inward to form an angle of 30° to position the third corner 3, and the third corner 3 is passed through two processes Continue to bend inwardly, the first process bends the third angle 3 to 15°, and the second process bends the angle bent in the first process to 3° to obtain the third angle 3 of 3°; this step (1 ) is completed on the lockstitch folding machine invented by our company.

[0036] (2) Continue to bend the second angle 2 of the part to be seamed obtained in step (1) through ...

Embodiment 3

[0040] Such as Figure 1-Figure 3 As shown, a metal roof panel lock seam method comprises the following steps:

[0041] (1) Set the 90° angle of the metal roof panel to be locked as the first angle 1; bend the lateral side of the first angle 1 inward to form an angle of 110° and set it as the second angle 2; set the second angle 2 The longitudinal side of the second angle 2 is bent inwardly to form an angle of 30° to position the third angle 3, and the third angle 3 is continuously bent inwardly through two processes. The first process bends the third angle 3 to 25°, and the second process bends the third angle 3 to the inside. The angle bent in the first process is then bent to 5° to obtain a third angle 3 of 5°; this step (1) is completed on the lockstitch folding machine invented by our company.

[0042](2) Continue to bend the second angle 2 of the part to be seamed obtained in step (1) through four processes, the first process bends to 89°, and the second process bends t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com