Continuous cutting device

A technology of cutting equipment and cutting wheel, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing device, etc., can solve the problems of low production efficiency and inability to automatically feed and cut pipe materials, and achieve high production efficiency and high automatic feeding and cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

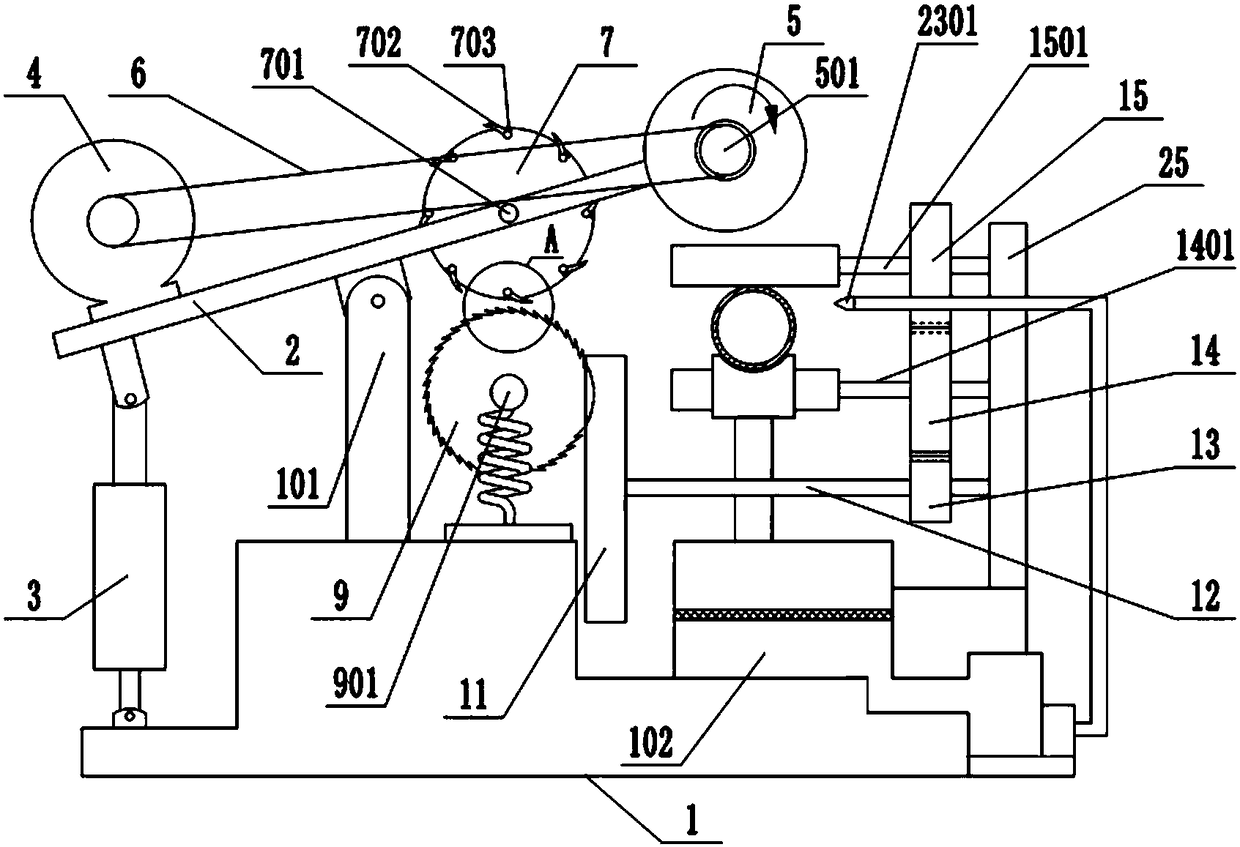

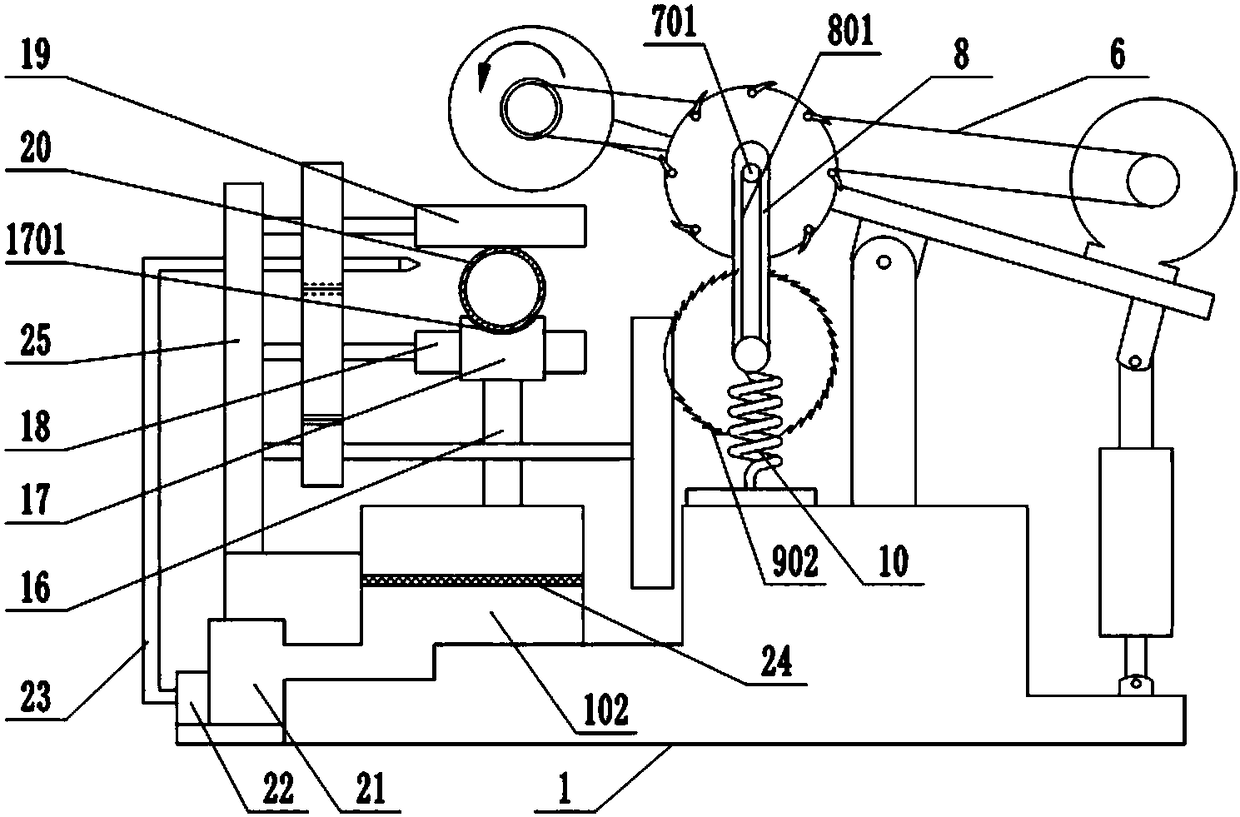

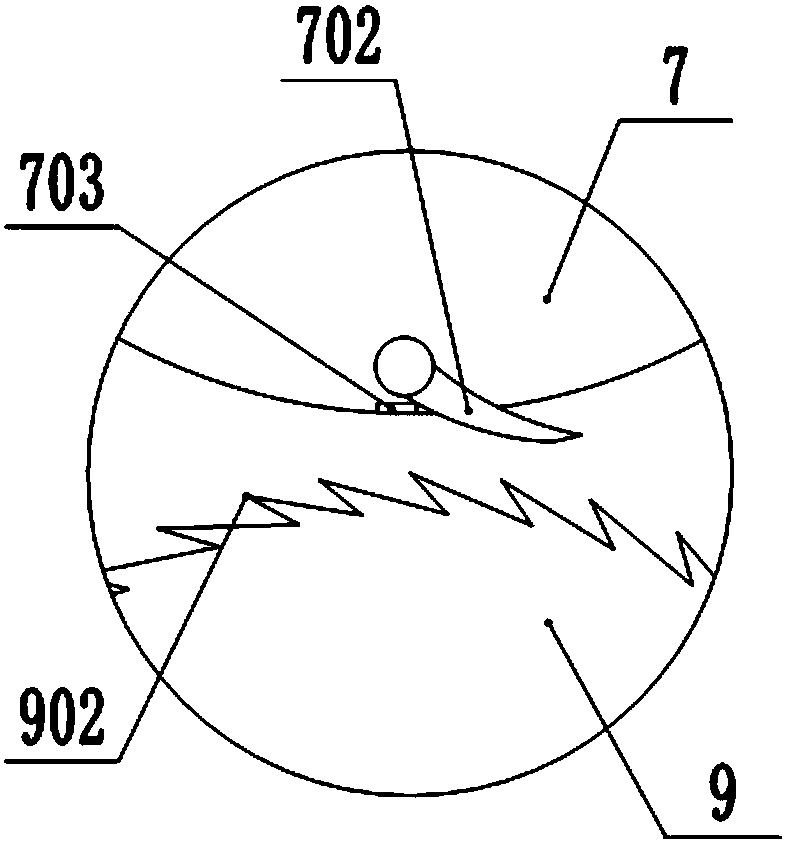

[0019] The reference signs in the accompanying drawings of the description include: frame 1, first support column 101, liquid collection tank 102, rotating plate 2, telescopic cylinder 3, cutting motor 4, cutting wheel 5, rotating shaft 501, belt 6, first rotation Wheel 7, first fixed shaft 701, ratchet 702, block 703, first sliding rod 8, sliding groove 801, second runner 9, second fixed shaft 901, ratchet 902, elastic support 10, first Transmission wheel 11, first transmission shaft 12, second transmission wheel 13, third transmission wheel 14, second transmission shaft 1401, fourth transmission wheel 15, third transmission shaft 1501, second support column 16, transmission rail 17, Arc groove 1701, cutting groove 1702, lower roller 18, upper roller 19, pipe material 20, liquid sump 21, pump 22, nozzle 23, liquid spray port 2301, filter screen 24, second support column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com