Cutter for cutting a coiled band

a cutter and coiled technology, applied in the field of cutters, can solve the problems of time-consuming and inconvenient, hand injury,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

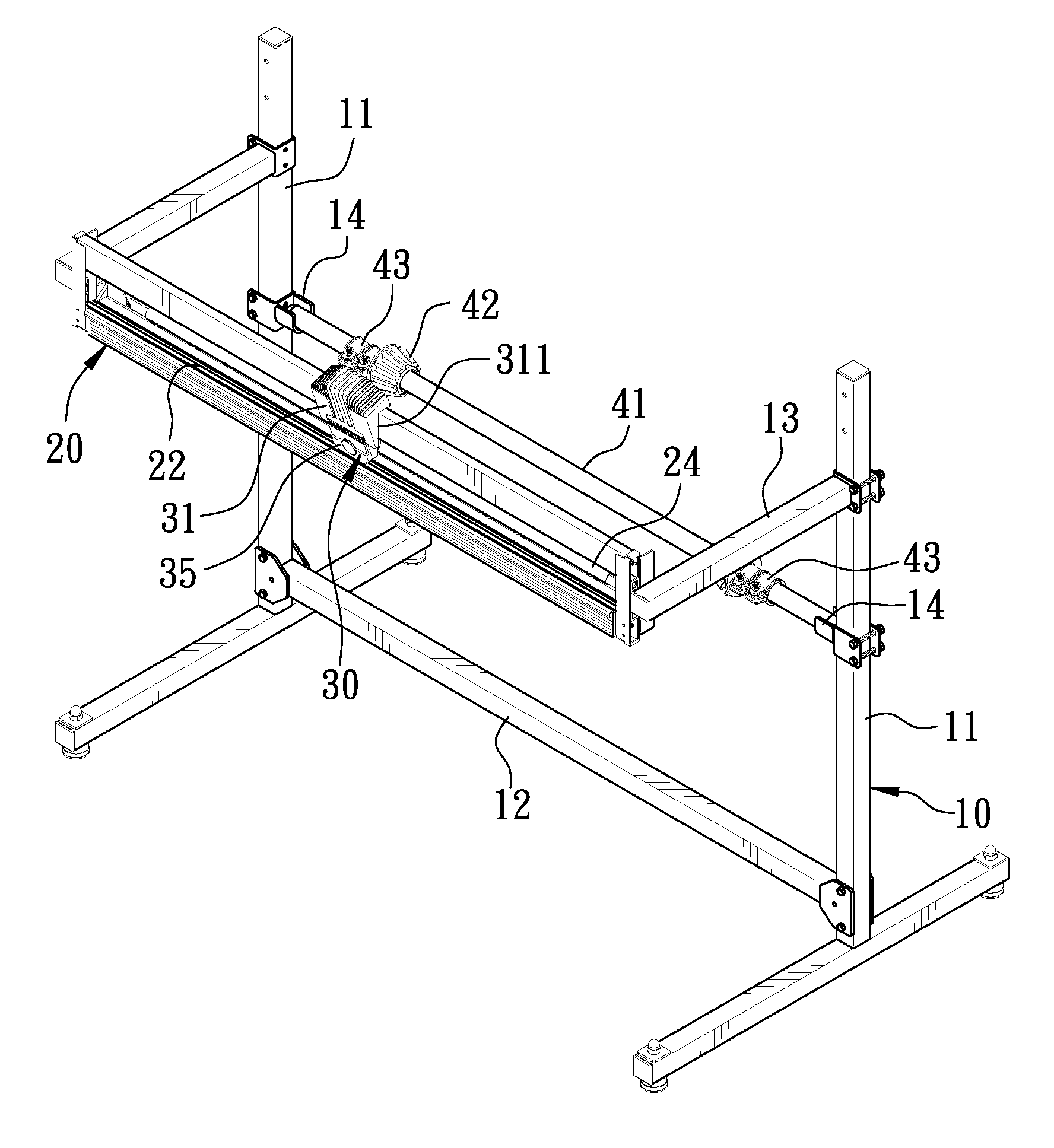

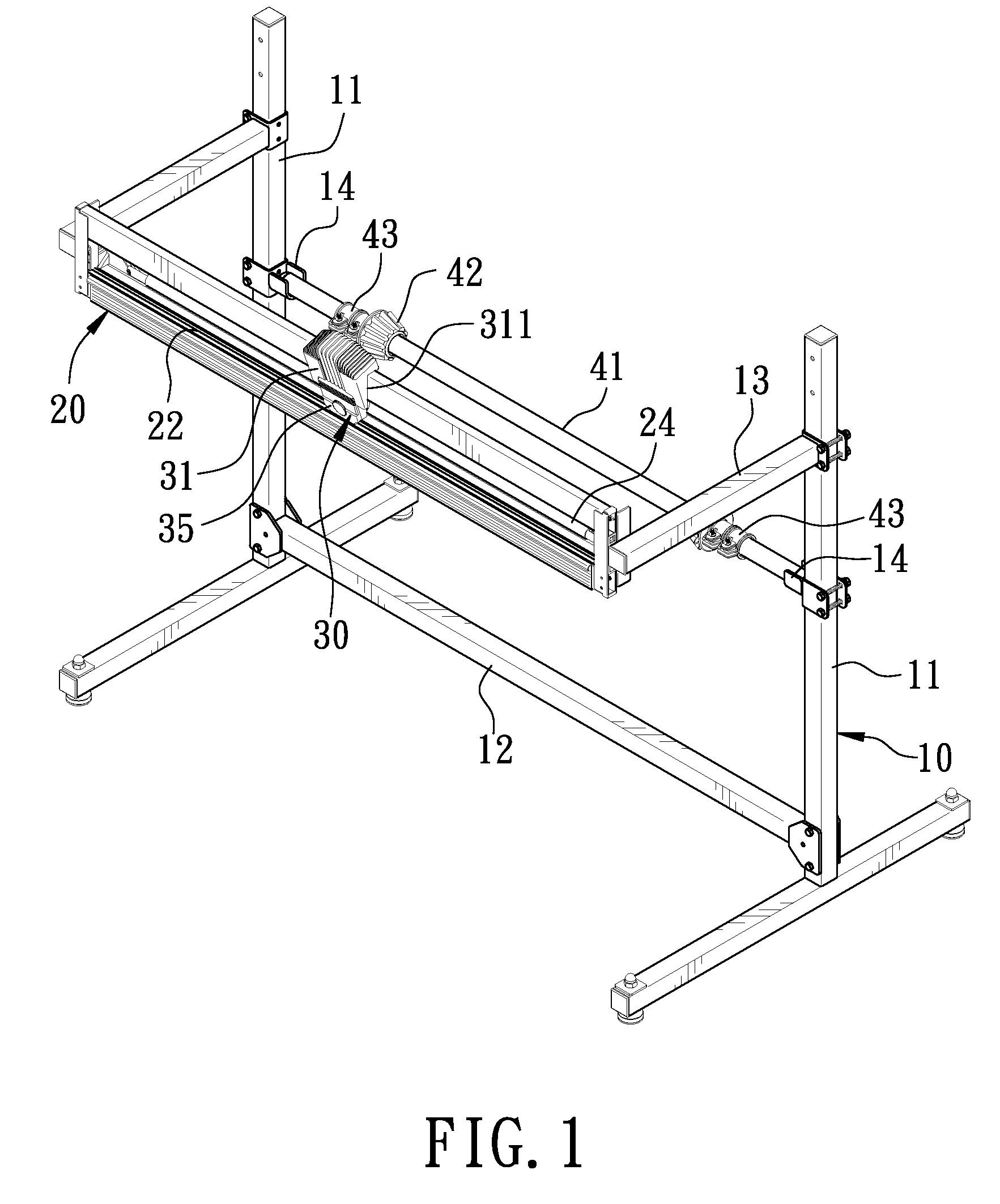

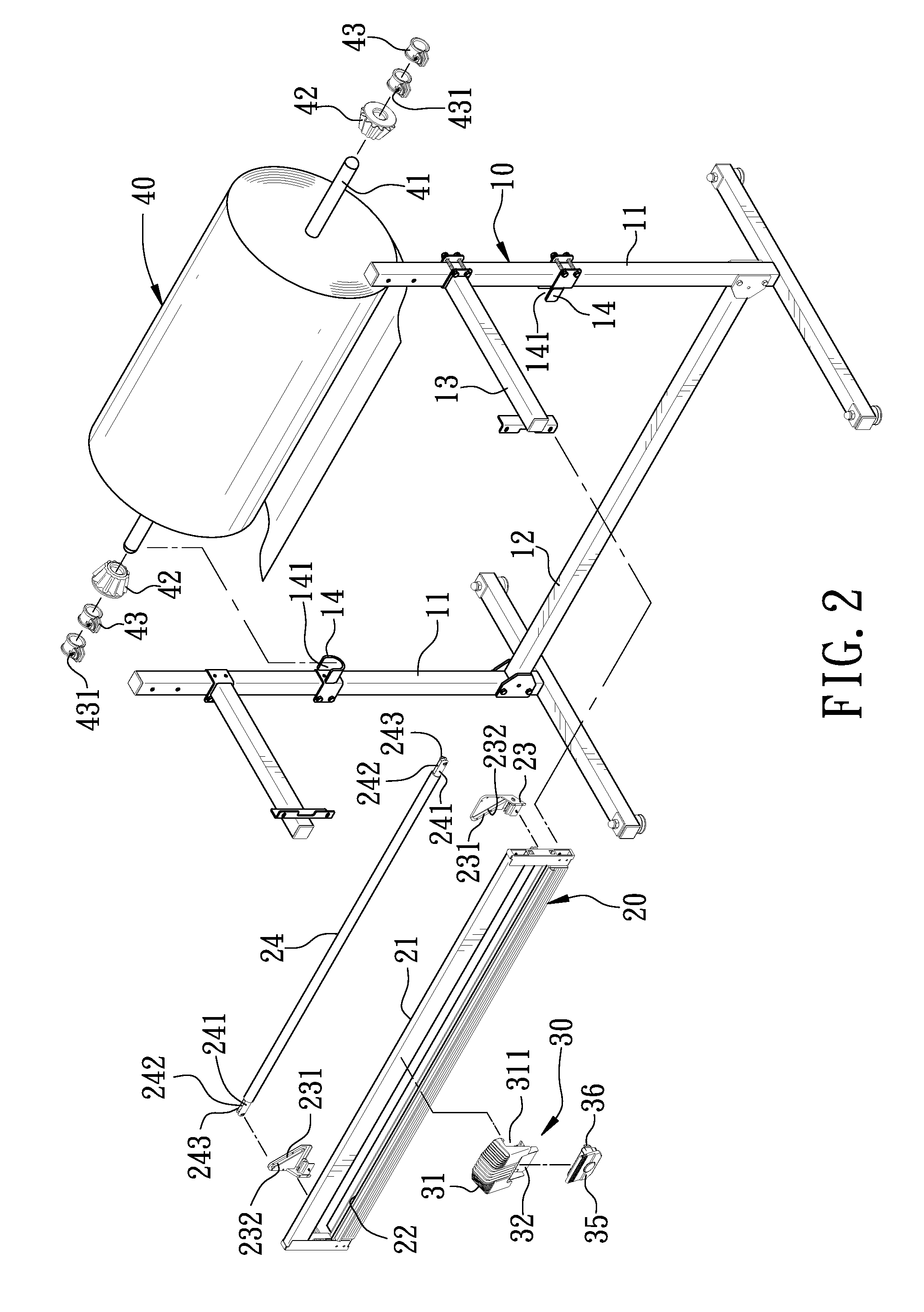

[0015]As shown in FIGS. 1 and 2, a first preferred embodiment of a cutter for cutting a coiled band in the present invention includes a main body 10, a cutting base 20 and a knife unit 30.

[0016]The main body 10 is vertically placed on the ground, provided with a T-shaped post 11 formed at its two sides respectively, reversely standing on the ground in parallel. A transverse rod 12 has its two ends connected to the bottom center of the T-shapes posts 11 respectively, and a front rod 13 is fixed at a preset position of each of the T-shaped posts 11 near the top, extended forward and parallel with each other. The main body 10 is also provided with a U-shaped supporter 14 that is located at a proper position of each of the T-shaped posts 11 below the front rod 13, having an opening facing upward and corresponding to each other. The U-shaped supporters 14 are employed to support two ends of a shaft 41 of a coiled band 40. The shaft 41 has its two ends pivotally engaged with a conical res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com