Mechanical automatic cutting device with dust collecting cover

A technology for cutting devices and dust collection hoods, which is applied in metal processing machinery parts, dust removal, chemical instruments and methods, etc., can solve problems affecting environmental sanitation and physical health, and achieve the effect of ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

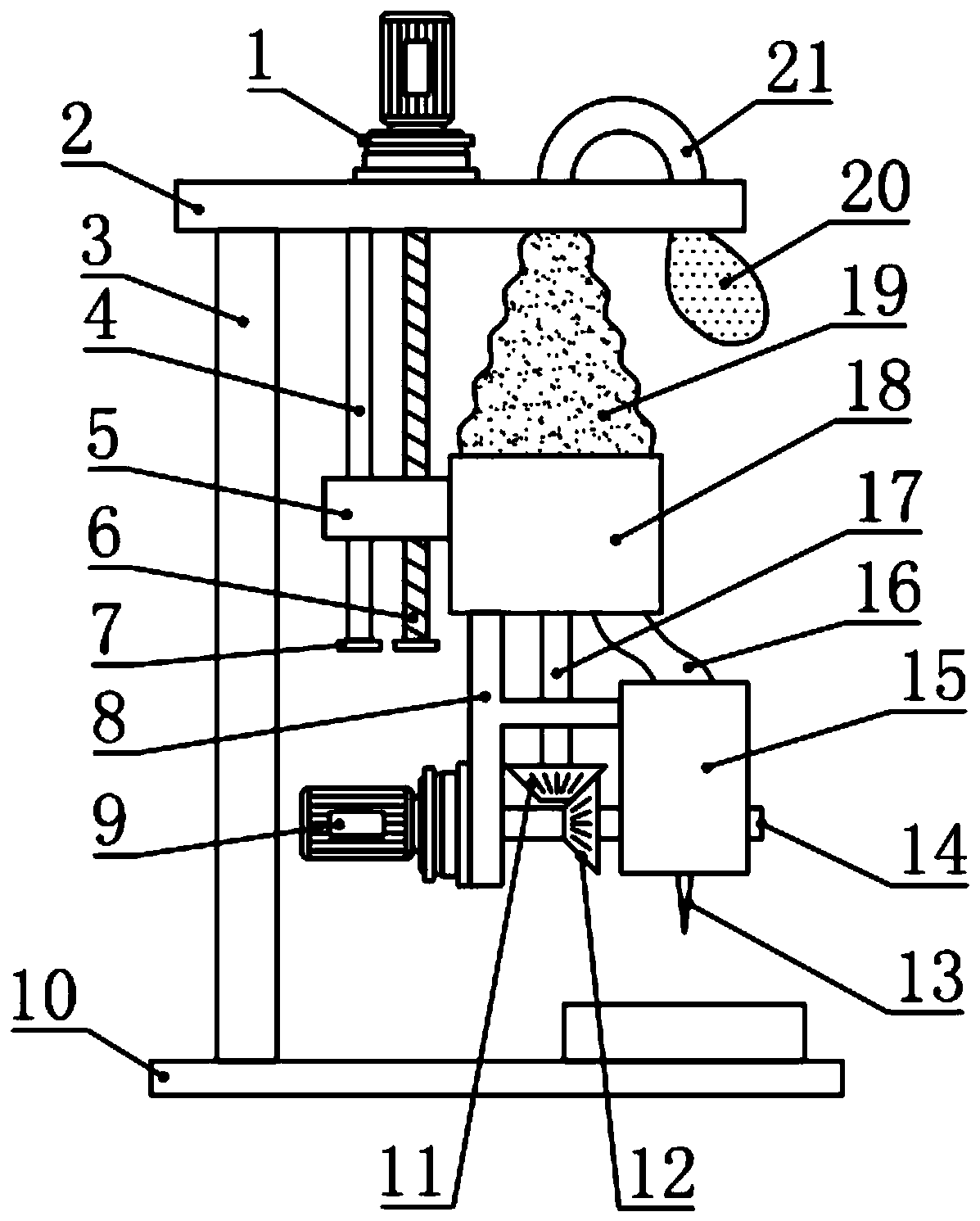

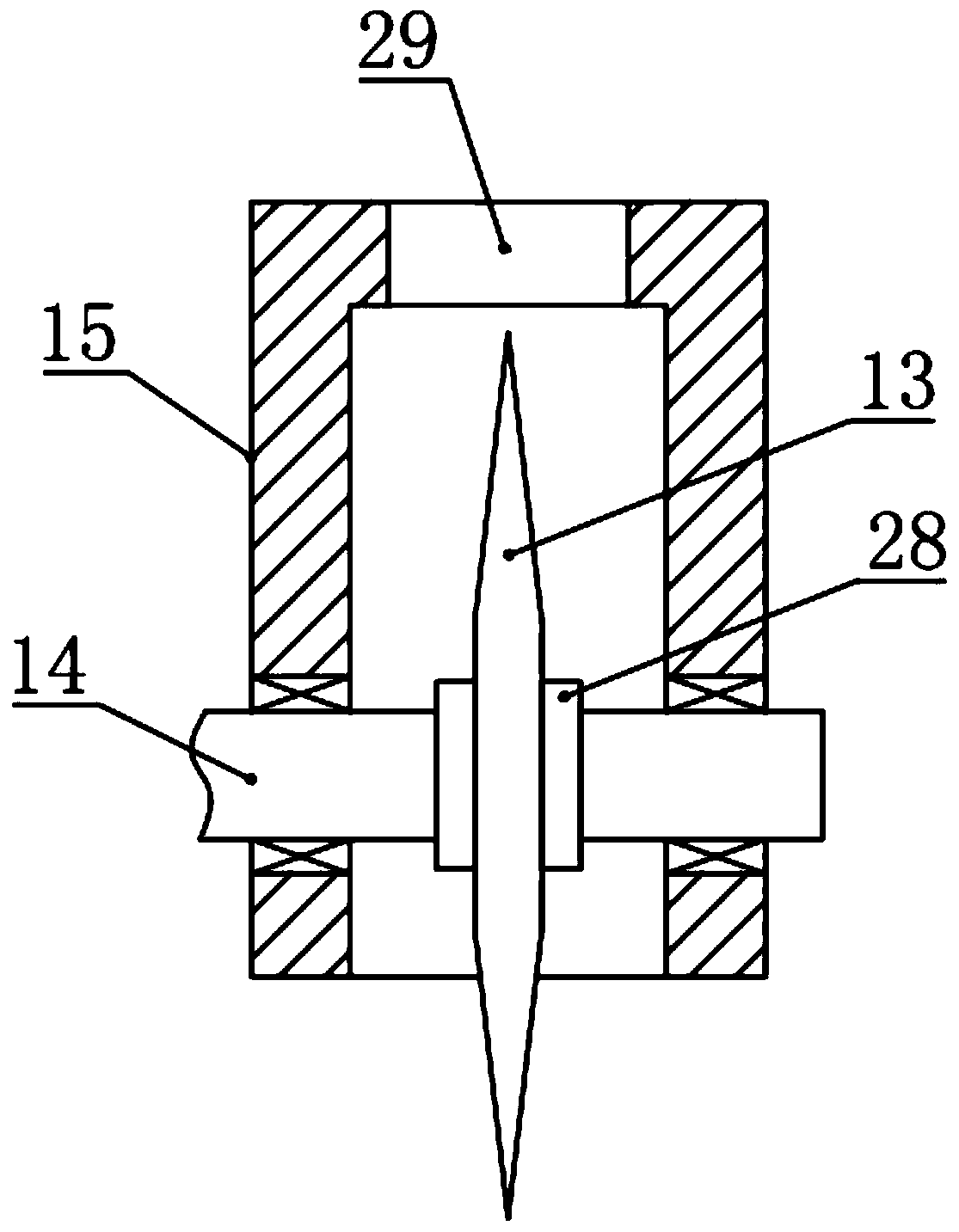

[0033] see Figure 1-4 , in an embodiment of the present invention, a mechanical automatic cutting device with a dust collection cover includes a top frame 2, a column 3, a base 10 and a cutting wheel 13, and the upper and lower ends of the column 3 are respectively fixed with a top frame 2 and the base 10, the underside of the top frame 2 is provided with a dust suction cylinder 18, and the dust suction cylinder 18 is driven to move up and down by a longitudinal drive device arranged on the top frame 2, and the bottom side of the dust suction cylinder 18 passes through the fixed frame 8 Support is fixed with horizontal shaft 14, and horizontal shaft 14 is driven to rotate by second motor 9, and cutting wheel 13 is installed on the horizontal shaft 14, and the outer cover of described cutting wheel 13 is provided with dust collection cover 15, and dust collection cover 15 is fixed with The frame 8 is fixedly connected, and the dust collection cover 15 is connected with the dus...

Embodiment 2

[0038] see Figure 1-2 , the difference between this embodiment and embodiment 1 is:

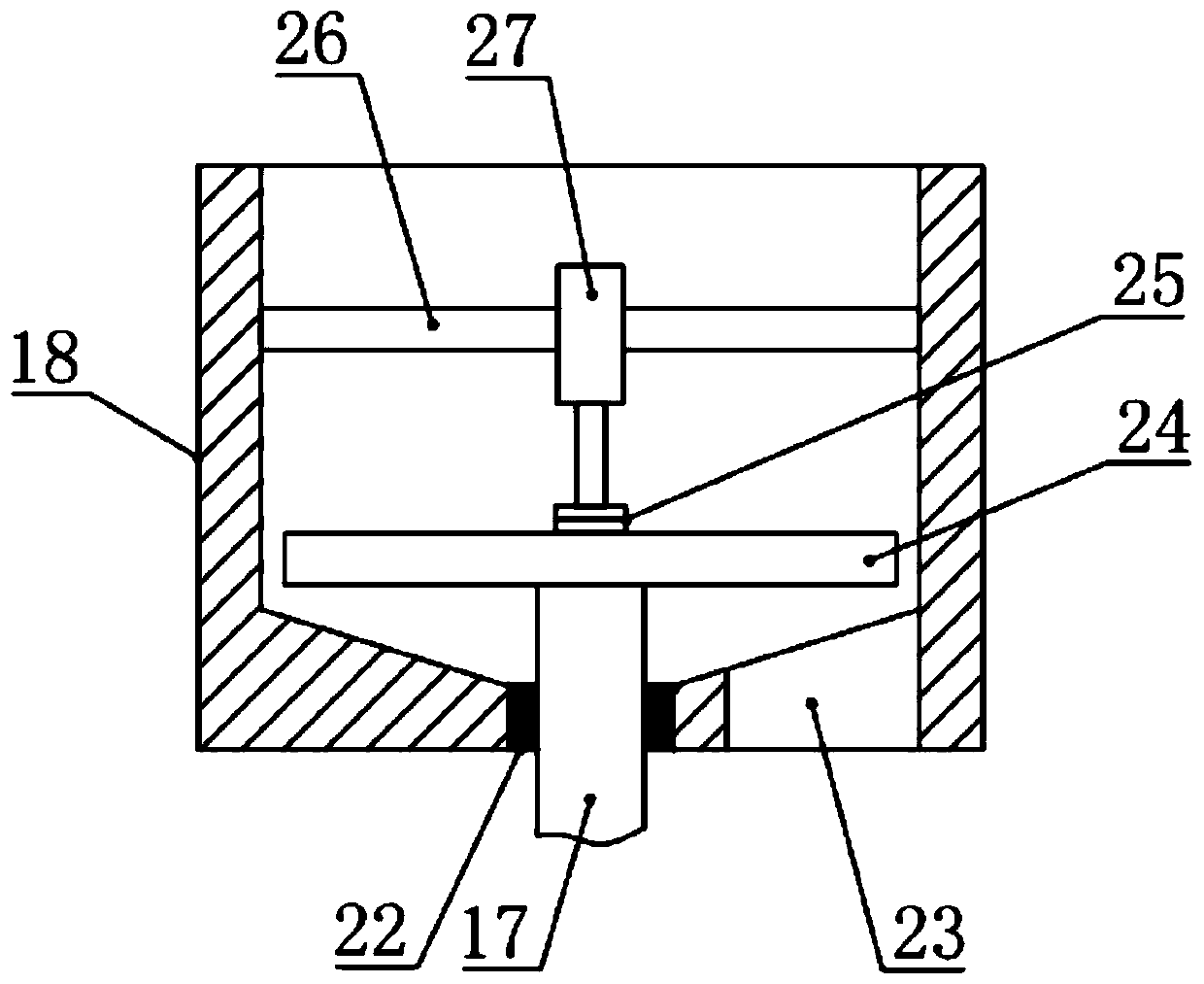

[0039] In this embodiment, the dust suction mechanism includes a first bevel gear 11, a second bevel gear 12, a vertical shaft 17, a fan blade 24, a rotating body 25, a cross bracket 26 and a telescopic cylinder 27, and the dust suction cylinder 18 is The upper opening of the cylindrical barrel, the bottom of the inner cavity of the dust suction cylinder 18 is a conical structure with the outer ring upturned, which is beneficial to dust collection. The bottom of 18 is also provided with a sliding sleeve 22 that cooperates with the vertical shaft 17. The vertical shaft 17 can rotate relative to the sliding sleeve 22 and move longitudinally. The fan blade 24 that sucks the air in the inner chamber of the vacuum tube 18 from bottom to top is installed and fixed on the upper end of the vertical shaft 17. The structure of the fan blade 24 can adopt the existing technology. Installed and fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com