Plastic pipe fitting cutting device with dust storing function

A plastic tube and cutting technology, used in metal processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inaccurate cutting and complicated cutting operations, and achieve high cutting stability and cutting operation. Convenient and fast, accurate cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

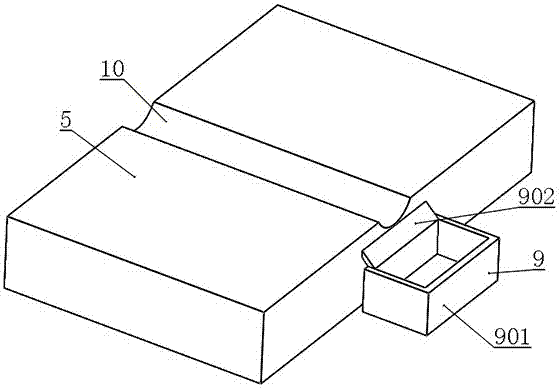

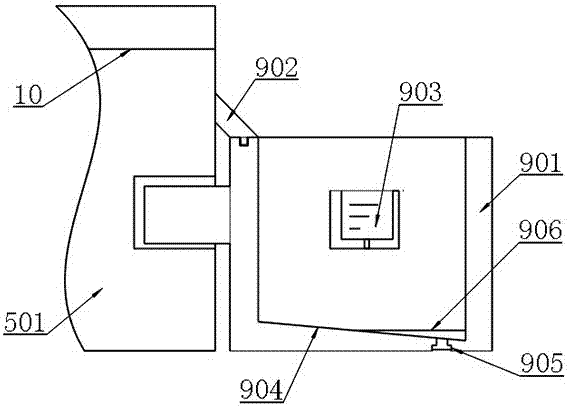

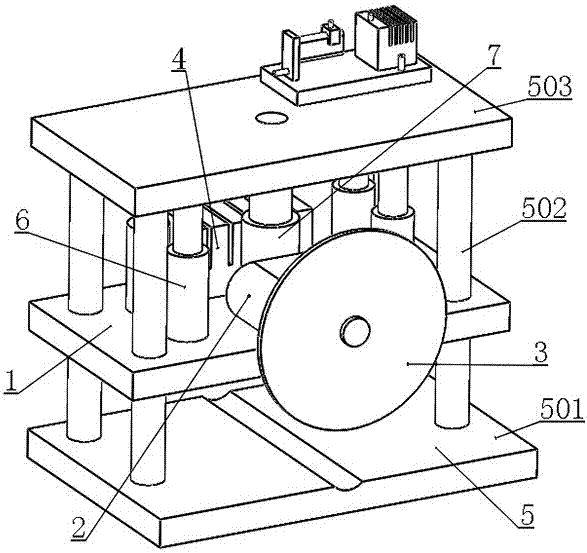

[0027] Example: as attached figure 1 , 2 , 3, 4, 5, 6, 7, 8 and attached Figure 9 As shown, a plastic pipe fitting cutting device with dust storage function includes a cutting mounting plate 1, a cutting motor 2 arranged on the cutting mounting plate 1, a cutting wheel 3, and a The battery pack 4 powered by the cutting motor 2 also includes a base unit 5 for plug-in installation and limit sliding of the cutting installation plate 1, which is arranged on the cutting installation plate 1 and tensioned by elastic The method is used to carry out the tensioning unit 6 on the base unit 5 for the cutting installation plate 1 to be suspended in the air, and is arranged on the base unit 5 and is used to drive the The driving unit 7 for cutting the mounting plate 1 for lowering and cutting, the side of the base unit 5 close to the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com