Spherical LiFexMnyPO4 anode material and preparation method thereof

A technology of lithium iron manganese phosphate and positive electrode materials, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor safety, high toxicity, and poor rate performance of lithium iron phosphate lithium manganese oxide. The preparation method is simple, the process is easy to control, and the particle size distribution is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a spherical lithium iron manganese phosphate positive electrode material, characterized in that the preparation process comprises the following steps:

[0029] 1) Weigh the lithium source, iron source, manganese source, and phosphorus source into the deionization solution, and ultrasonically disperse to obtain solution I, in which the molar ratio of lithium source, iron source, manganese source, and phosphorus source is 1.0~1.2:x:y :1.0~1.5, x+y=1;

[0030] 2) Add 5wt%~15wt% carbon source compound into solution I, and stir evenly to form solution II;

[0031] 3) Add surfactant CTAB to solution II, stir for 0.5h to obtain solution III, wherein the molar ratio of CTAB to lithium source is 0.05~0.2:1;

[0032] 4) Add EDTA to solution Ⅲ and stir for 0.5h to obtain solution Ⅳ, in which the molar ratio of EDTA to lithium source is 0.2~1:1;

[0033] 5) Transfer solution IV into a high-pressure reactor, and conduct hydrothermal reaction at 180°C for 6-1...

Embodiment 1

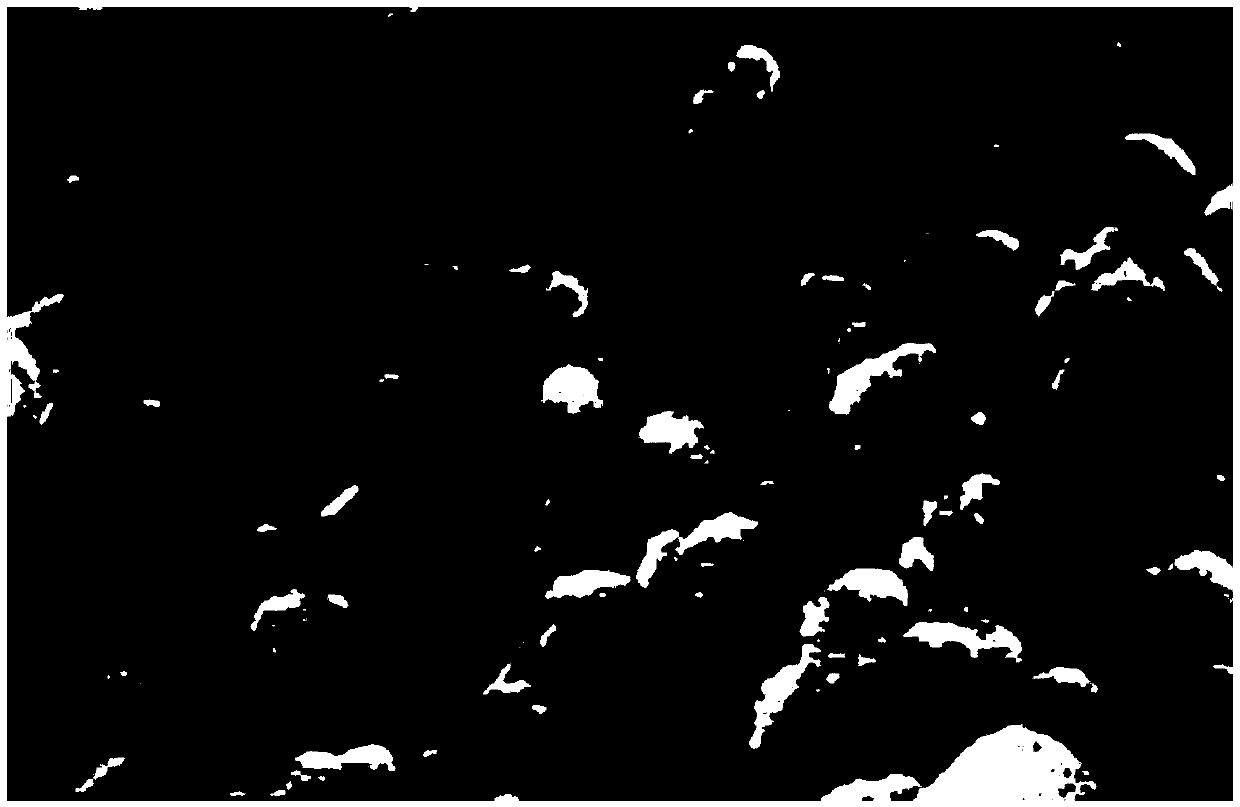

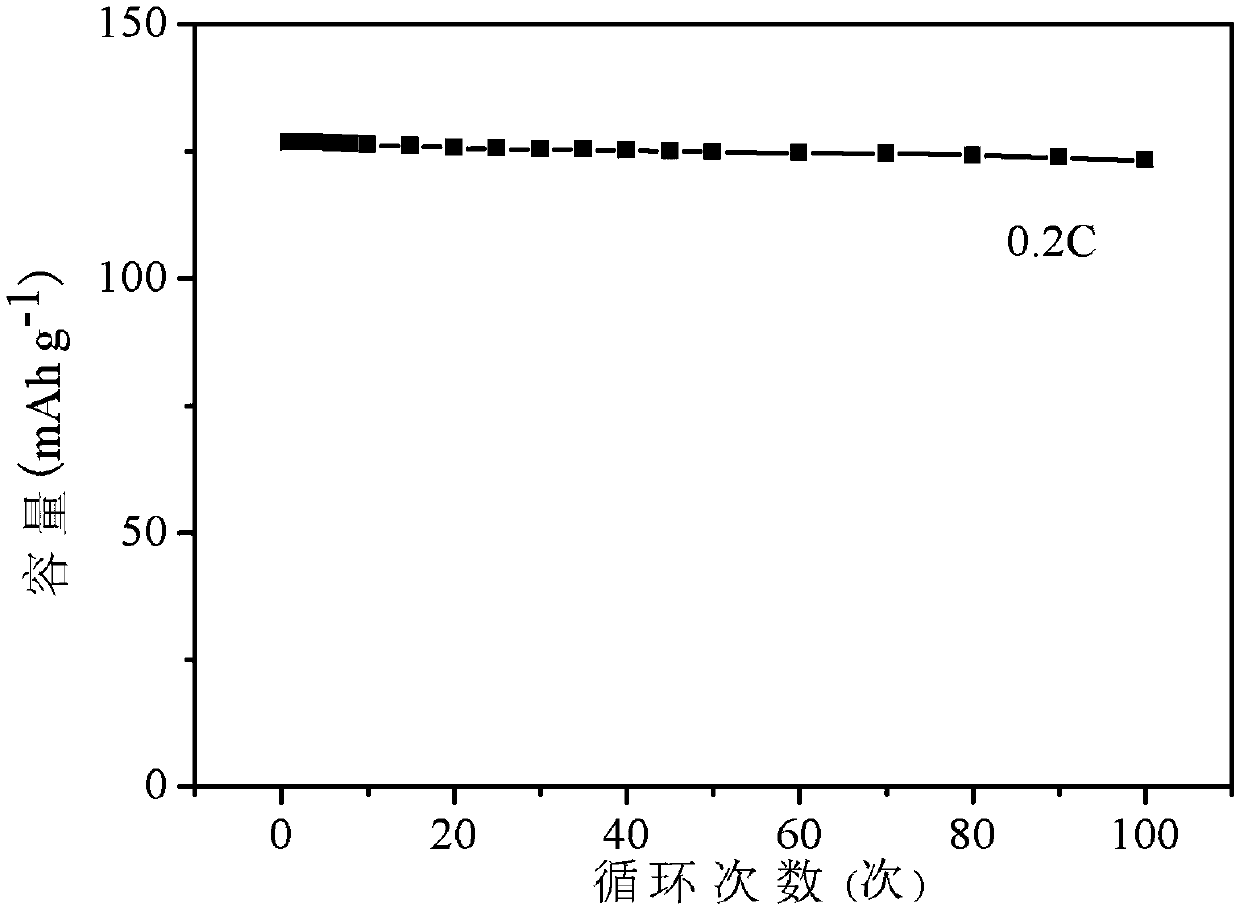

[0039] First, weigh lithium hydroxide, ferrous sulfate, manganese acetate, and phosphoric acid with a molar ratio of 1.0~1.2:0.5:0.5:1.0~1.5 and add them to deionization, ultrasonically disperse, and then add glucose with a mass fraction of metal salt of 10wt% After ultrasonic dispersion, stir for a period of time until it is completely dissolved, then add a certain amount (n(CTAB):n(LiOH)=0.05:1) of surfactant CTAB, stir for 0.5h until CTAB is completely dissolved, and then add a certain amount (n(LiOH)=0.05:1) (EDTA):n(LiOH)=0.2:1) of EDTA, stirred for 0.5h to obtain a stable and uniform solution. The solution was transferred into a high-pressure reactor, and a hydrothermal reaction was carried out at 180° C. for 6 hours. After the solution was cooled, it was filtered, washed, and dried to obtain a lithium iron manganese phosphate precursor. Put the lithium iron manganese phosphate precursor powder into a tubular calciner, calcinate at 800° C. for 8 hours in a nitrogen atmos...

Embodiment 2

[0042] First, weigh lithium hydroxide, ferrous sulfate, manganese acetate, and phosphoric acid with a molar ratio of 1.0~1.2:0.6:0.4:1.0~1.5 and add them to deionization, ultrasonically disperse, and then add glucose with a mass fraction of metal salt of 10wt% After ultrasonic dispersion, stir for a period of time until completely dissolved, then add a certain amount (n(CTAB):n(LiOH)=0.1:1) of surfactant CTAB, stir for 0.5h until CTAB is completely dissolved, then add a certain amount (n (EDTA):n(LiOH)=0.5:1) of EDTA, stirred for 0.5h to obtain a stable and uniform solution. The solution was transferred into a high-pressure reactor, and a hydrothermal reaction was carried out at 180° C. for 8 hours. After the solution was cooled, it was filtered, washed, and dried to obtain a lithium iron manganese phosphate precursor. The precursor powder of lithium iron manganese phosphate was put into a tubular calciner, calcined at 600° C. for 10 h in a nitrogen atmosphere, and ground afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com