Multicomponent nano porous palladium-base alloy and preparation method thereof

A nanoporous, palladium-based alloy technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult to control alloy ratio, inability to mass production, unfavorable promotion and application, etc. Achieve the effect of good alloying degree, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh pure Al powder, pure Cu powder, pure Ti powder and pure Pd powder (purity ≥ 99.5%, mass ratio) in sequence according to the atomic percentage of 60% Al, 30% Cu, 4% Ti and 6% Pd. Weigh 30g. Use a stainless steel ball mill tank, weigh stainless steel balls according to the ball-to-material ratio of 15:1, and weigh the grinding aid (stearic acid) with a mass ratio of 10 mm, 6 mm, and 4 mm in diameter of the grinding balls 1:1:1 , and its weight is 1~2% (mass ratio) of the powder.

[0035] (2) Add the powder and balls into the ball mill tank in the order of "ball first, then feed", set the speed of the high-energy ball mill to 400 rpm, stop for 10 minutes every 30 minutes, set the automatic forward and reverse, The ball milling time is 100 hours, and the Al-Pd-Cu-Ti alloy powder is obtained after the ball milling treatment.

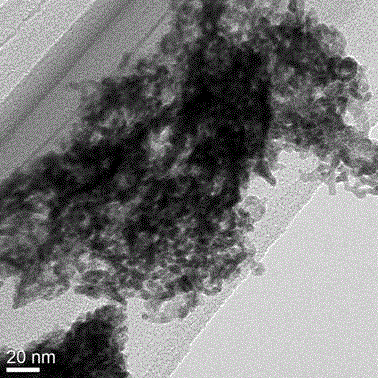

[0036] (3) The Al-Cu-Pd-Ti alloy powder was ultrasonically cleaned in absolute ethanol, and the sample was rinsed with deionized water aft...

Embodiment 2

[0040]Except that the pure Al powder, pure Cu powder, pure Ti powder and pure Pd powder (purity ≥ 99.5%, mass ratio) are weighed sequentially according to the atomic percentage of 55% Al, 30% Cu, 5% Ti and 10% Pd, other same Example 1. The obtained multi-component nanoporous Pd alloy powder has a size of 300 nm and a nanopore diameter of 4 nm.

Embodiment 3

[0042] Except that the pure Al powder, pure Cu powder, pure Ti powder and pure Pd powder (purity ≥ 99.5%, mass ratio) are weighed sequentially according to the atomic percentage of 75% Al, 20% Cu, 4% Ti and 1% Pd, other same Example 1. The obtained multi-component nanoporous Pd alloy powder has a size of 100 nm and a nanopore diameter of 2.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com