Method for preparing lignin sodium sulfonate dispersant through advanced catalytic oxidation

A technology of sodium lignosulfonate and advanced catalytic oxidation, which is applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc. Improve sulfonation effect, solve the problem of black liquor pollution, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

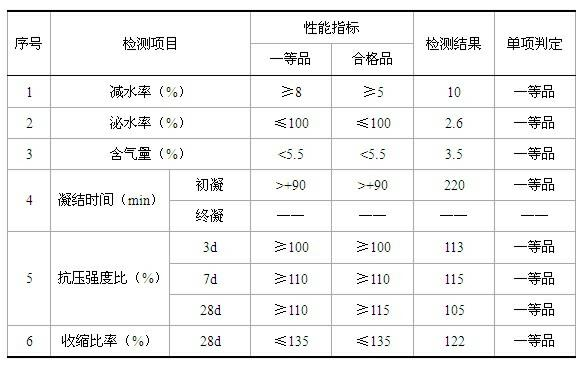

Examples

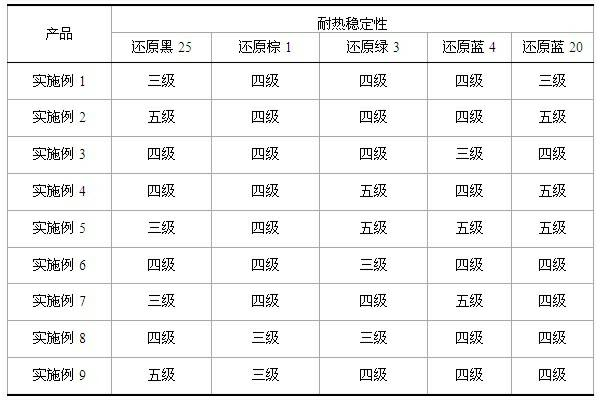

Embodiment 1

[0039] 1. The raw material components used in this embodiment are as follows (unit——kilogram):

[0040] Pulping black liquor (bamboo and masson pine pulping black liquor mixed, mass ratio 1:1, solid content 40%): 200 kg

[0041] Catalyst (mixture of ferrous sulfate / copper sulfate / sodium gluconate, mass ratio 1:1:0.1): 0.047 kg

[0042] Hydrogen peroxide (30% content): 5.5 kg

[0043] Concentrated sulfuric acid (98% content): 1.02 kg

[0044] Sodium α-hydroxymethanesulfonate: 19.44 kg

[0045] Water: 81.9 kg

[0046] 2. Preparation process steps and parameters

[0047] (1) Catalytic oxidation: Mix 0.047 kg of catalyst and 0.11 kg of water to make a 30% solution, mix it with 200 kg of pulping black liquor with a solid content of 40%, add it to the reactor, and react at 35°C for 30 minutes. Add 5.5kg of hydrogen peroxide and react at 80°C for 30min. Then use 1.02 kg of concentrated sulfuric acid and 4.0 kg of water to make a 20% solution, and adjust the pH of the system to...

Embodiment 2

[0050] 1. The raw material components used in this embodiment are as follows (unit——kilogram):

[0051] Pulping black liquor (mixed straw and birch pulp black liquor, mass ratio 3:2, solid content 52%): 850 kg

[0052] Catalyst (mixture of ferrous chloride / cobalt nitrate / thiourea dioxide, mass ratio 0.5:1:0.2): 0.1 kg

[0053] Potassium permanganate: 6.0 kg

[0054] Concentrated phosphoric acid (85% content): 3.0 kg

[0055] Sodium α-hydroxymethanesulfonate: 41.0 kg

[0056] Water: 100.0 kg

[0057] 2. Preparation process steps and parameters

[0058] (1) Catalytic oxidation: Mix 0.1 kg of catalyst and 0.4 kg of water into a 20% solution, mix it with 850 kg of pulping black liquor with a solid content of 52%, add it to the reactor, and react at 40°C for 20 minutes. Mix 6.0 kg of potassium permanganate and 14.0 kg of water to form a 30% solution, add it to the above reaction system at 60°C, and react for 45 minutes. Then use 9.8 kg of concentrated phosphoric acid and 24....

Embodiment 3

[0061] 1. The raw material components used in this embodiment are as follows (unit——kilogram):

[0062] Pulping black liquor (wheat straw and reed pulping black liquor mixed, mass ratio 1:4, solid content 35%): 100 kg

[0063] Catalyst (mixture of nickel sulfate / cobalt nitrate, mass ratio 3:1): 0.035 kg

[0064] Peracetic acid (35% content): 5.1 kg

[0065] Citric acid: 0.76 kg

[0066] Sodium alpha-hydroxymethanesulfonate: 15.87 kg

[0067] Water: 87.65 kg

[0068] 2. Preparation process steps and parameters

[0069] (1) Catalytic oxidation: 0.035 kg of catalyst and 0.32 kg of water are prepared into a 10% solution, mixed with 100 kg of pulping black liquor with a solid content of 35%, added to the reactor, and reacted at 60°C for 30 minutes. Add 5.1 kg of peracetic acid and react at 80°C for 60 min. Then use 0.76 kg of citric acid and 6.84 kg of water to make a 10% solution, and adjust the pH of the system to 13.0.

[0070] (2) Sulfomethylation: Mix 15.87 kg of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com