Reductive spherical cellulose adsorbent containing sulfinyl and preparation method thereof

A technology based on sulfinic acid and cellulose, applied in chemical instruments and methods, and other chemical processes, to achieve good economic and social benefits, simple production process, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

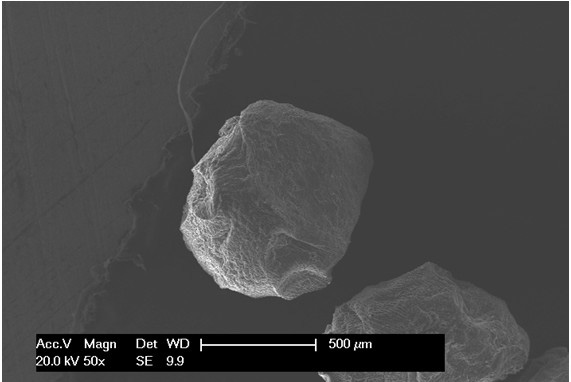

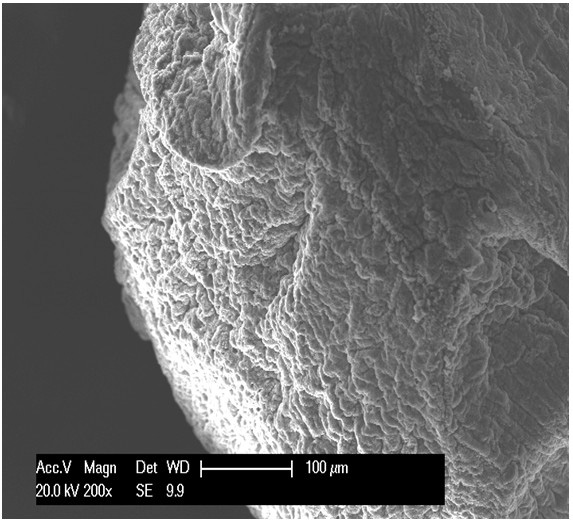

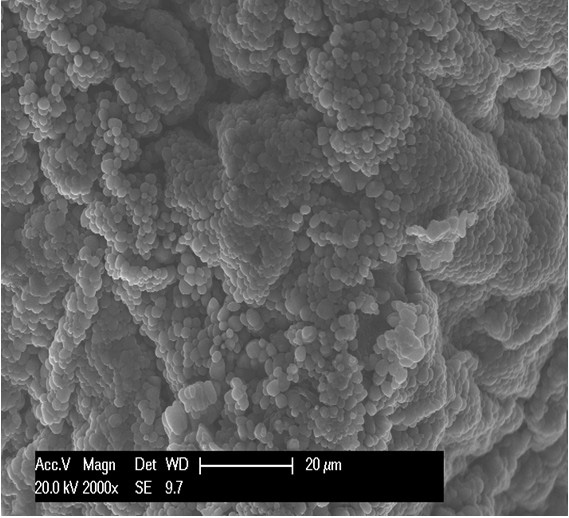

Image

Examples

Embodiment 1

[0034] Example 1: The specific steps of this embodiment are as follows:

[0035] (1) Graft copolymerization of cellulose in ionic liquid:

[0036] The raw material components used in this embodiment are as follows (unit——kilogram):

[0037] Cellulose absorbent cotton: 0.2 kg

[0038] Ionic liquid ([BMIM]Cl): 15.0 kg

[0039] Initiator (potassium persulfate): 0.01 kg

[0040] Acrylamide compound (acrylamide): 0.5 kg

[0041] Process steps and parameters of cellulose graft copolymerization in ionic liquid: put 0.2 kg of absorbent cotton and 15.0 kg of ionic liquid ([BMIM]Cl) into the reactor, dissolve at 100°C for 4 h, and form a mass fraction of 1.32% cellulose-ionic liquid solution; cool the above solution to 50°C, add 0.01 kg potassium persulfate, react for 15 min, then add 0.5 kg acrylamide, react for 2 h; then spray the reaction solution into distilled water with a spray gun, Stir at a speed of 150 r / min to make it solidify into a ball. Take out and filter, and wash...

Embodiment 2

[0050] Example 2: The specific steps of this embodiment are as follows:

[0051] (1) Graft copolymerization of cellulose in ionic liquid:

[0052] The raw material components used in this embodiment are as follows (unit——kilogram):

[0053] Masson pine alkali pulping fiber: 6.0 kg

[0054] Ionic liquid ([AMIM]Cl): 75.0 kg

[0055] Initiator (ammonium persulfate): 1.0 kg

[0056] Acrylamide compounds (N’,N-methylenebisacrylamide): 18.0 kg

[0057] Process steps and parameters of graft copolymerization of cellulose in ionic liquid: put 6.0 kg of absorbent cotton and 75.0 kg of ionic liquid ([AMIM]Cl) into the reactor, dissolve at 90°C for 6 h, and form a mass fraction of 7.41% cellulose-ionic liquid solution; cool the above solution to 60°C, add 1.0 kg of ammonium persulfate, react for 5 min, then add 18.0 kg of N',N-methylenebisacrylamide, react for 1 h; then use a spray gun The reaction solution was sprayed into distilled water, stirred at a speed of 150 r / min at room t...

Embodiment 3

[0066] Example 3: The specific steps of this embodiment are as follows:

[0067] (1) Graft copolymerization of cellulose in ionic liquid:

[0068] The raw material components used in this embodiment are as follows (unit——kilogram):

[0069] Birch kraft fiber: 4.0 kg

[0070] Ionic liquid ([EMIM]Cl): 81.9 kg

[0071] Initiator (cobalt acetylacetonate): 0.9 kg

[0072] Acrylamide compounds (N’,N-methylenebisacrylamide): 13.2 kg

[0073] Process steps and parameters of graft copolymerization of cellulose in ionic liquid: 4.0 kg of absorbent cotton and 81.9 kg of ionic liquid ([EMIM]Cl) were put into the reactor, dissolved at 120°C for 2 h, and the resulting mass fraction was 4.66% cellulose-ionic liquid solution; cool the above solution to 40°C, add 0.9 kg of cobalt acetylacetonate, react for 20 min, then add 13.2 kg of N', N-methylenebisacrylamide, react for 3 h; then use a spray gun The reaction solution was sprayed into distilled water, stirred at a speed of 150 r / min a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com