Acetylated hydroxypropyl potato starch, preparation method thereof and application thereof

A technology for acetylating hydroxypropyl and potato starch, which can be used in food preparation, starch-derived adhesives, applications, etc., and can solve the problems of poor viscosity, insufficient advantages, and poor retrogradation resistance of hydroxypropyl starch , to achieve the effect of low cost, abundant raw materials and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

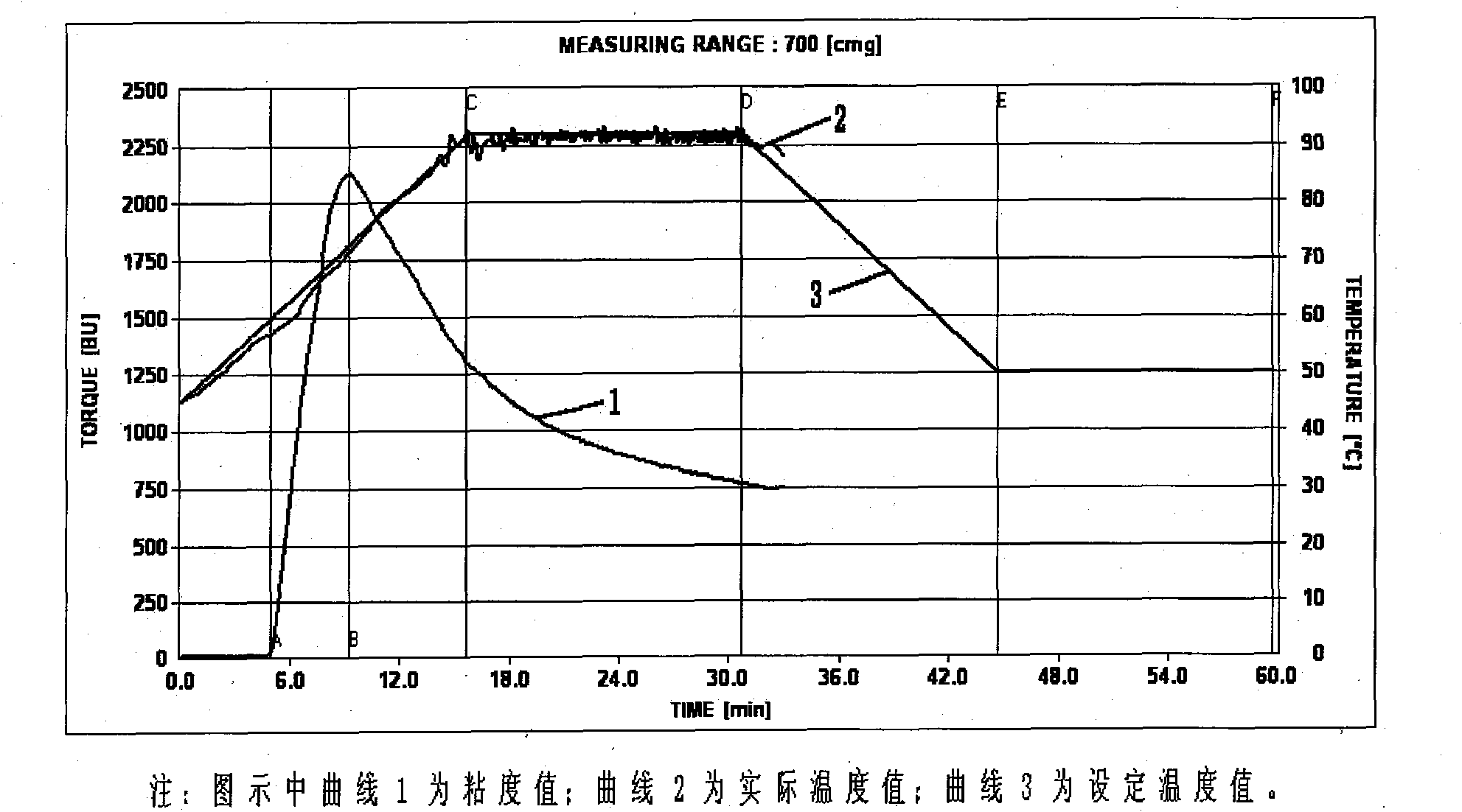

Embodiment 1

[0045] The preparation of embodiment 1 acetylated hydroxypropyl potato starch

[0046] Prepare acetylated hydroxypropyl potato starch according to the following steps:

[0047] 1) Slurry: 28.5Kg anhydrous Na 2 SO 4 Dissolve 15kg of solid NaOH in 260kg of water, then dissolve 210kg of potato starch in the solution, stir to obtain starch milk;

[0048] 2) Etherification: Add 3.8% sodium hydroxide lye to the starch milk in step 1) to pH = 10.90, stir for half an hour; add 12.6Kg of propylene oxide, seal, stir for one hour, and heat up the starch milk to 42°C-43°C; after 20 hours of reaction, cool down and neutralize to pH=8.20;

[0049] 3) Esterification: add 5.25Kg of acetic anhydride to carry out esterification reaction, and add 3.8-% sodium hydroxide lye to keep the pH between 8.20-8.40;

[0050] 4) Neutralization: after the reaction, neutralize to pH=5.5 with 9% hydrochloric acid;

[0051] 5) Washing: washing with a cyclone washer; drying: first dehydrating to ≤45% with ...

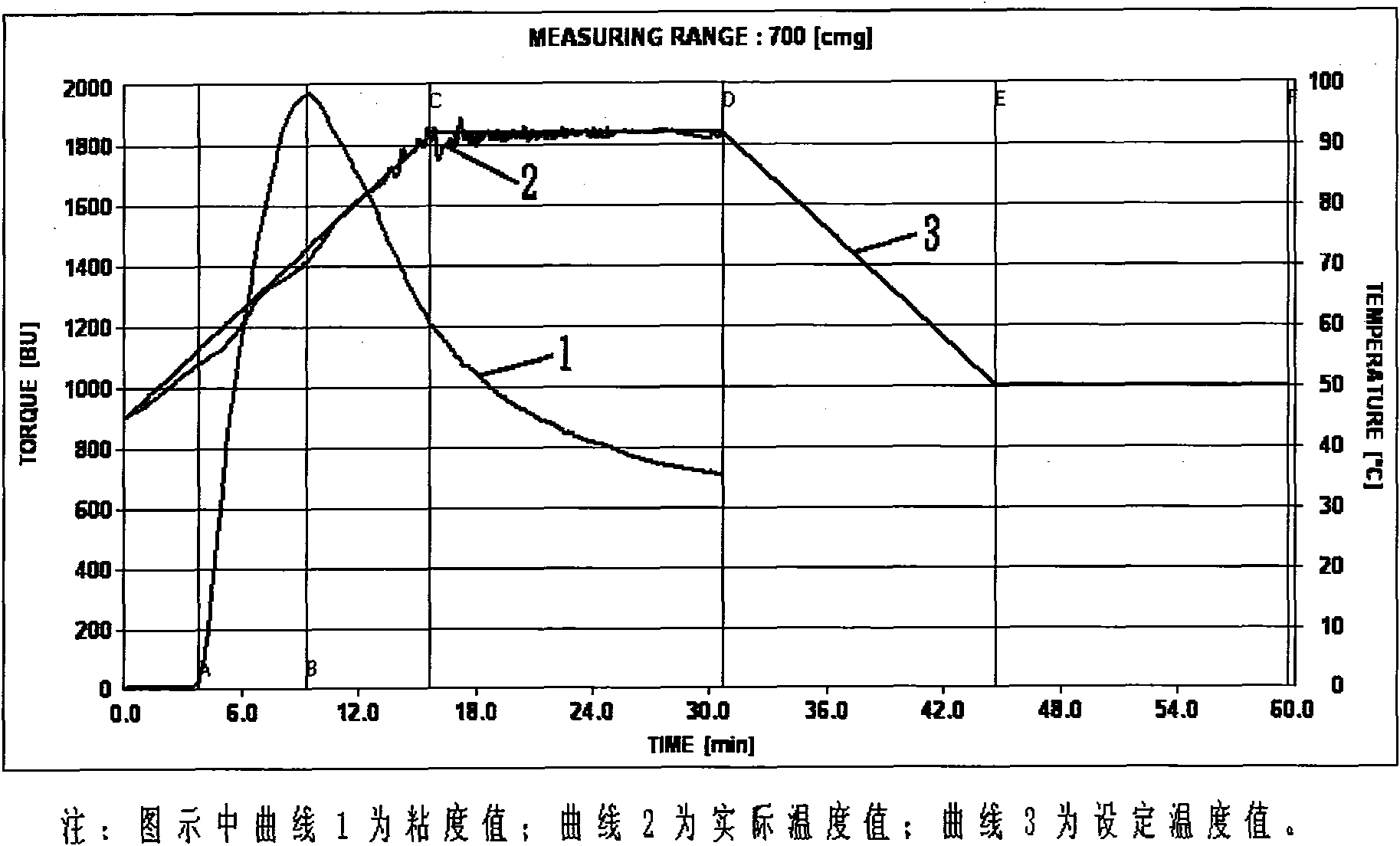

Embodiment 2

[0054] The preparation of embodiment 2 acetylated hydroxypropyl potato starch

[0055] Prepare acetylated hydroxypropyl potato starch according to the following steps:

[0056] 1) Slurry mixing: 28.5kg anhydrous Na 2 SO 4 Dissolve 1.5kg of solid NaOH in 255kg of water, then dissolve 215kg of potato starch in the solution, stir to obtain starch milk;

[0057] 2) Etherification: Add 4.2% sodium hydroxide lye to the starch milk in step 1) to pH = 11.30, stir for half an hour; add 15.05Kg of propylene oxide, seal, stir for one hour, and heat up the starch milk to 42°C-43°C; after 24 hours of reaction, cool down and neutralize to pH=8.20;

[0058] 3) Esterification: add 6.45Kg of acetic anhydride to carry out the esterification reaction, and add 4.2% sodium hydroxide alkali to keep the pH at 8.40;

[0059] 4) Neutralization: after the reaction, neutralize to pH=6.0 with 11% hydrochloric acid;

[0060] 5) Washing: Washing with a cyclone washer; Drying: First use a centrifugal s...

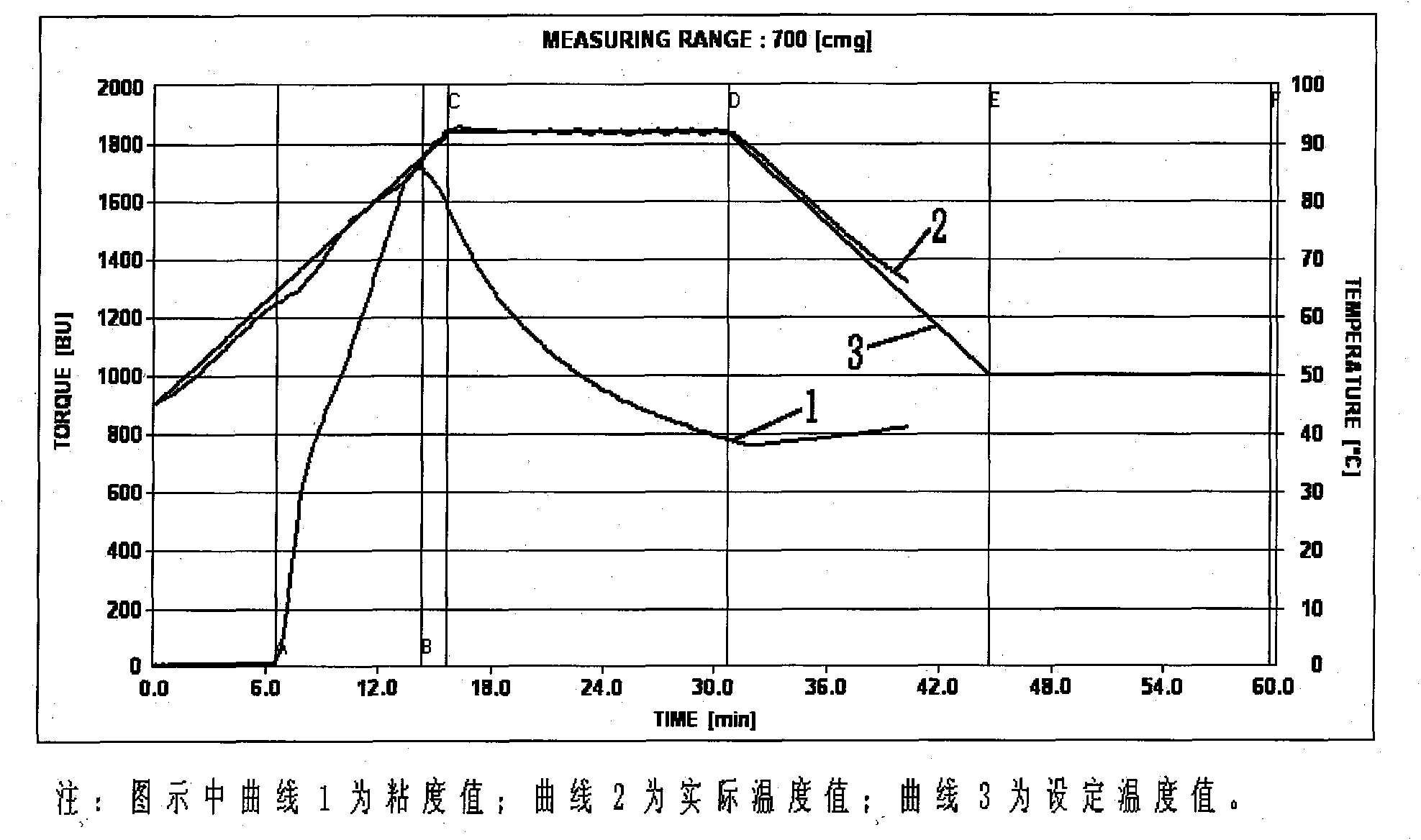

Embodiment 3

[0063] The preparation of embodiment 3 acetylated hydroxypropyl potato starch

[0064] Prepare acetylated hydroxypropyl potato starch according to the following steps:

[0065] 1) Slurry mixing: 28.5kg anhydrous Na 2 SO 4 Dissolve 1.5kg of solid NaOH in 255kg of water, then dissolve 215kg of potato starch in the solution, stir to obtain starch milk;

[0066] 2) Etherification: Add 3.8% sodium hydroxide lye to the starch milk in step 1) to pH = 11.10, stir for half an hour; add 17.2kg of propylene oxide, seal, stir for one hour, and heat up the starch milk to 41°C-42°C; after 22 hours of reaction, cool and neutralize to pH=8.30;

[0067] 3) Esterification: add 6.45Kg of acetic anhydride to carry out esterification reaction, and add 4.0% sodium hydroxide lye to keep the pH at 8.20;

[0068] 4) Neutralization: after the reaction, neutralize to pH=6.5 with 10% hydrochloric acid;

[0069] 5) Washing: Washing with a cyclone washer; Drying: First use a centrifugal scraper to deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com