Equipment for separating current collector of lithium ion battery from active material on current collector

A technology for lithium ion batteries and active materials, which is applied in the field of equipment for separating lithium ion battery current collectors and active materials thereon, can solve the problems of inconvenient operation, high cost, unfavorable mass production and the like, and achieves simple structure, low cost, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

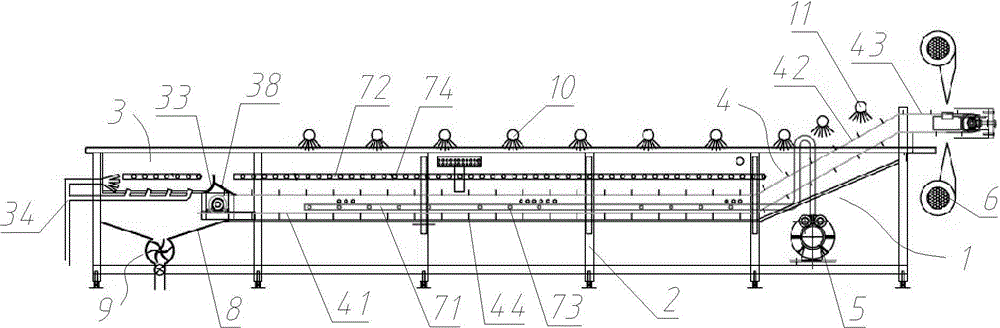

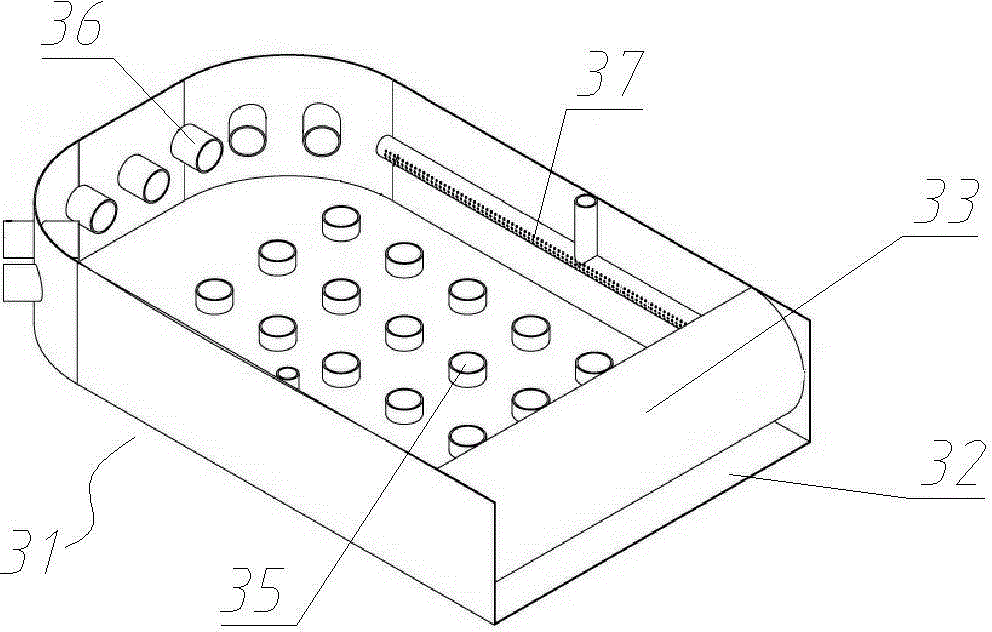

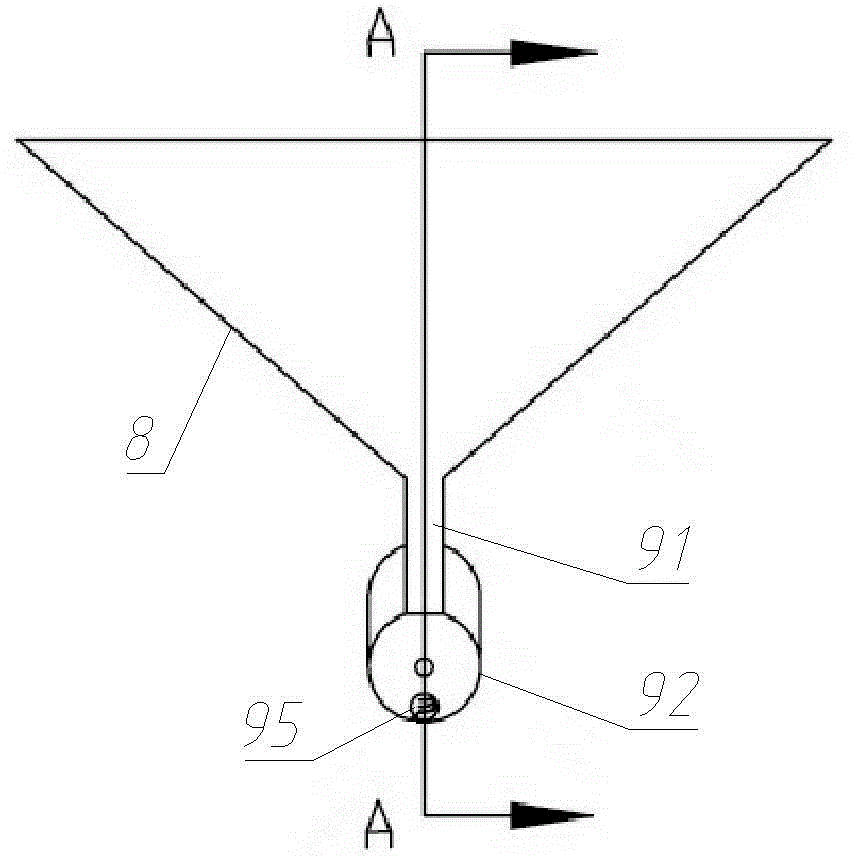

[0023] The embodiment of the device for separating lithium ion battery current collector and active material thereon of the present invention is the same as Figure 1~Figure 4 As shown, it includes a processing tank 1 for containing processing liquid and a frame 2 for supporting the processing tank 1. The cavity of the processing tank 1 is a rectangular parallelepiped, and the front end of the tank cavity is provided with a feeding dispersing device 3, a feeding dispersing device 3 An active material crushing device 9 is provided below and a scraper conveyor belt 4 is provided behind. The equipment also includes a vortex pump 5 for generating compressed gas, and two upper and lower fans 6 arranged at the end of the scraper conveyor 4 for drying the separated current collector.

[0024] The belt body of the scraper conveyor belt 4 is a closed endless belt body with a width equivalent to the width of the processing tank 1, which can prevent the current collector from passing betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com