Cu-Ni-Al alloy powder and preparation method thereof

A cu-ni-al, alloy powder technology, which is applied in the field of raw materials and preparation of anode materials for molten carbonate fuel cells, can solve the problem that the performance of sintered products cannot meet the performance requirements of anode materials, the sintering is difficult to control, and the sample expands. problem, to achieve the effect of small segregation, good crystallinity and high powder forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

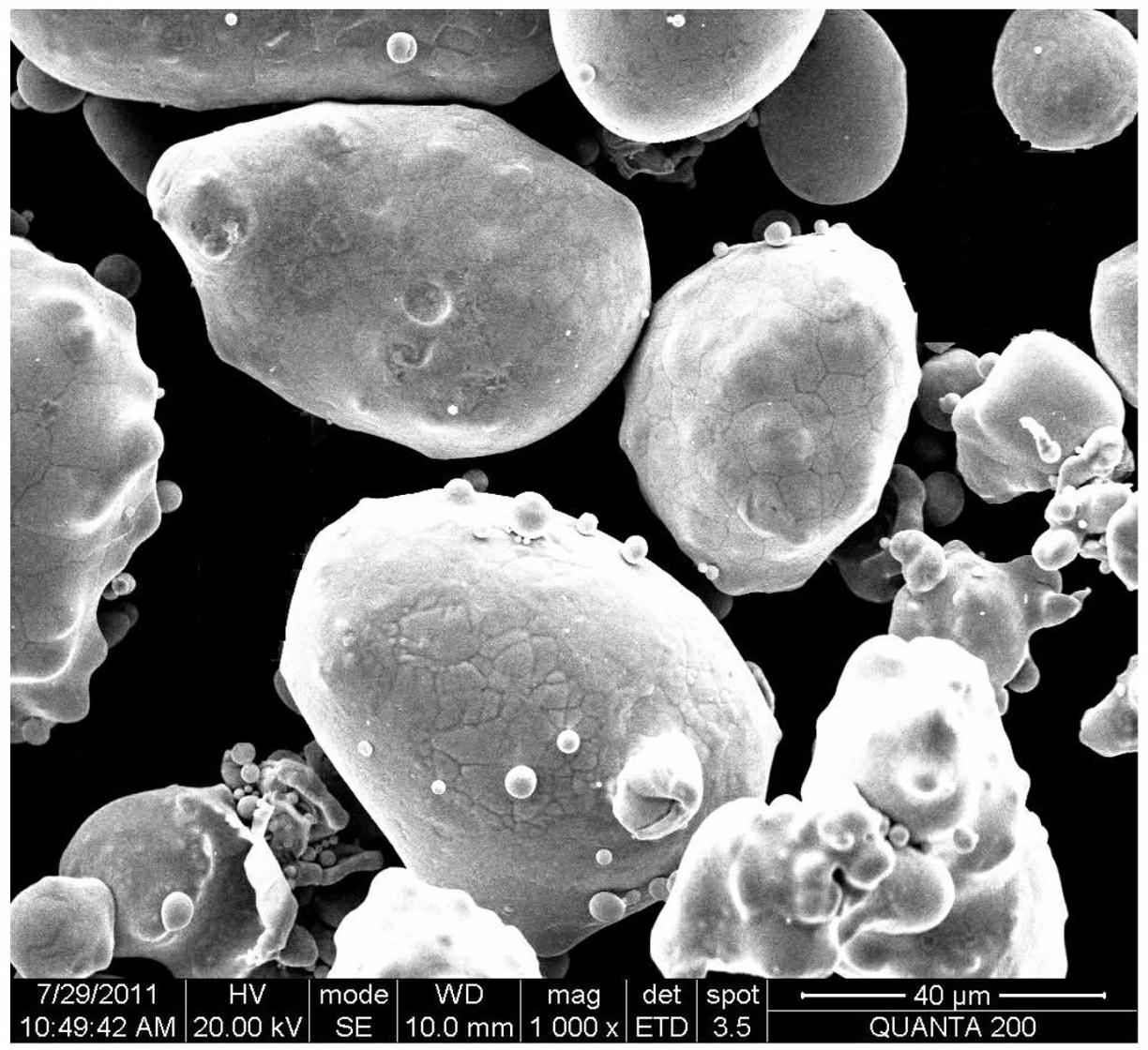

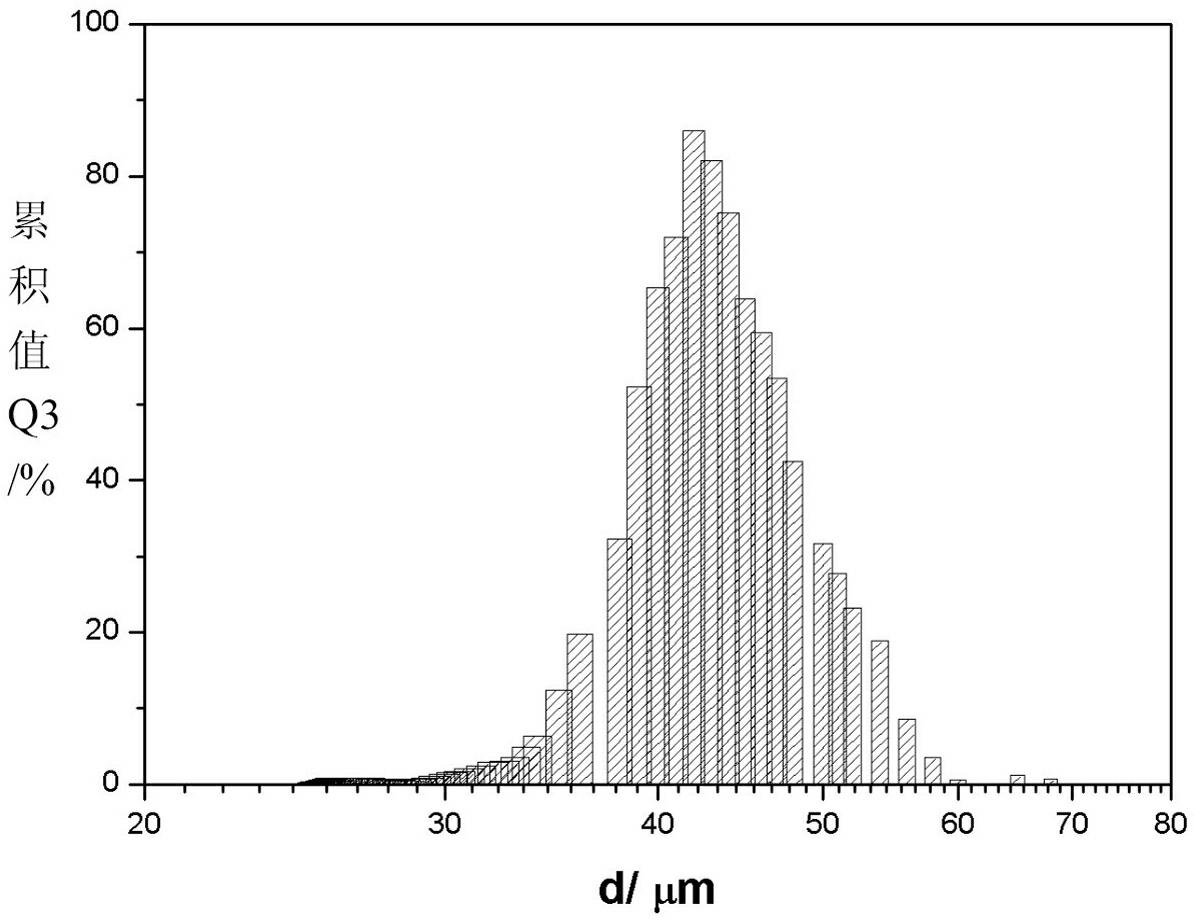

[0024] A kind of Cu-Ni-Al alloy powder of the present invention, this alloy powder is made of metallic Cu phase and AlNi interphase, the average particle diameter of alloy powder is 40 μm~50 μm, alloy powder has no macroscopic segregation, and the oxygen content of alloy powder is 0.0112%, the mass fractions of Cu, Ni and Al in the alloy powder are: Cu 60% 、 Ni 25% and Al 15% (negligible impurities).

[0025] The Cu-Ni-Al alloy powder of this embodiment is mainly prepared through the following steps:

[0026] (1) Alloy smelting: Put 6.0Kg of electrolytic Cu block with a purity of 99.99% and 2.5Kg of electrolytic Ni block with a purity of 99.96% in an intermediate frequency induction furnace (the process parameters of the intermediate frequency induction furnace are controlled as follows: current 20A, frequency 20Hz) graphite crucible, after Cu and Ni are melted, add 1.5Kg of electrolytic Al with a purity of 99.95% for melting;

[0027] (2) Refining of the alloy: When the tem...

Embodiment 2

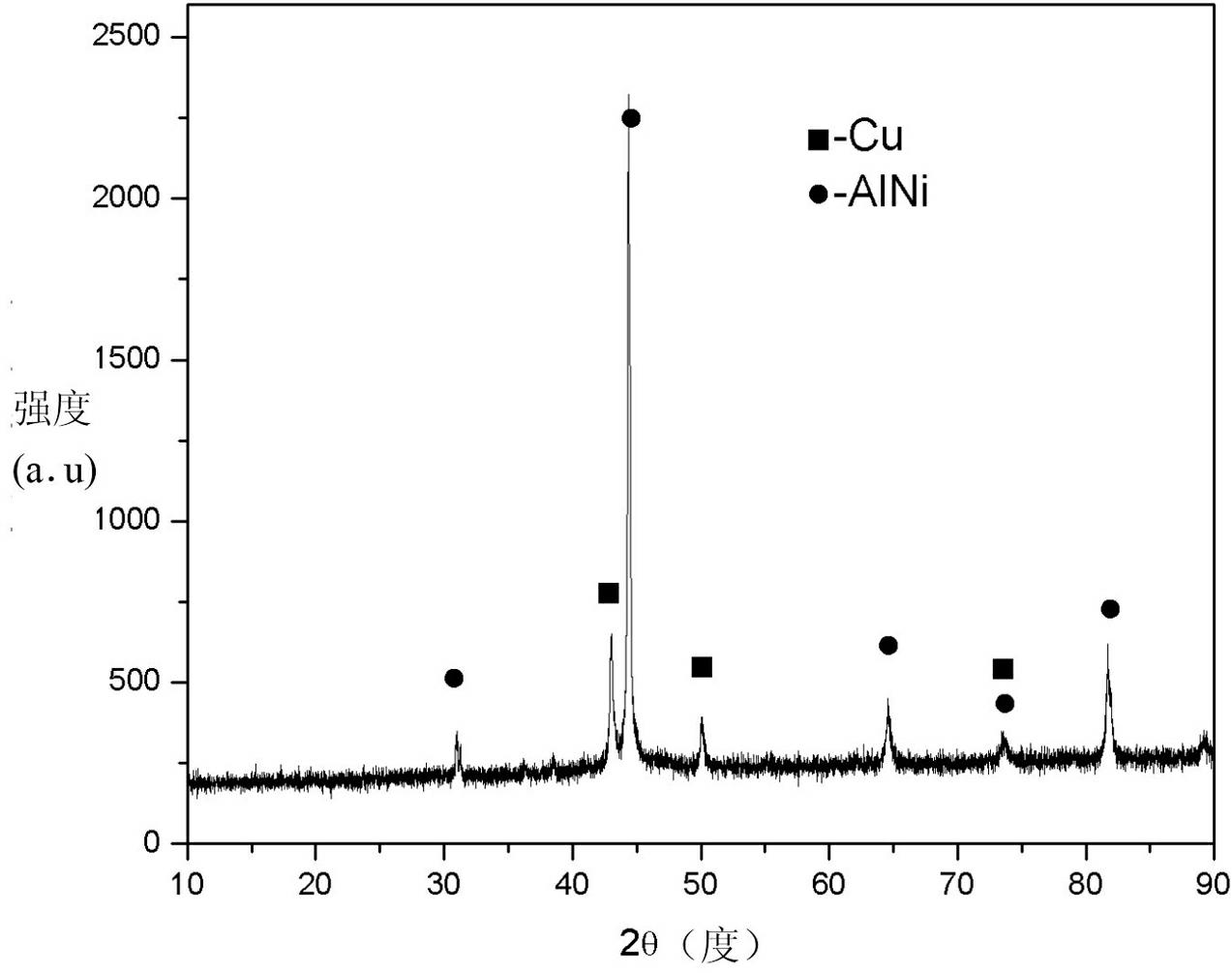

[0030] a kind of like figure 1 Shown Cu-Ni-Al alloy powder of the present invention, the X-ray diffraction pattern of alloy powder is as figure 2 As shown, the alloy powder is composed of metal Cu phase and AlNi intermediate phase, the average particle size of the alloy powder is 40 μm to 50 μm, the alloy powder has no macro-segregation, the oxygen content of the alloy powder is 0.0105%, and the Cu, Ni and The mass fractions of Al are: Cu 55%、 Ni 35% and Al 10% (negligible impurities).

[0031] The Cu-Ni-Al alloy powder of this embodiment is mainly prepared through the following steps:

[0032] (1) Alloy smelting: Put 5.5Kg of electrolytic Cu block with a purity of 99.99% and 3.5Kg of electrolytic Ni block with a purity of 99.96% in an intermediate frequency induction furnace (the process parameters of the intermediate frequency induction furnace are controlled as follows: current 20A, frequency: 30Hz) graphite crucible, after Cu and Ni are melted, add 1.0Kg of electrolytic...

Embodiment 3

[0037] A kind of Cu-Ni-Al alloy powder of the present invention, this alloy powder is made of metallic Cu phase and AlNi interphase, the average particle diameter of alloy powder is 40 μm~50 μm, alloy powder has no macroscopic segregation, and the oxygen content of alloy powder is 0.013%, the mass fractions of Cu, Ni and Al in the alloy powder are: Cu 50% 、 Ni 35% and Al 15% (negligible impurities).

[0038] The Cu-Ni-Al alloy powder of this embodiment is mainly prepared through the following steps:

[0039] (1) Alloy smelting: Put 5.0Kg of electrolytic Cu block with a purity of 99.99% and 3.5Kg of electrolytic Ni block with a purity of 99.96% in an intermediate frequency induction furnace (the process parameters of the intermediate frequency induction furnace are controlled as follows: current 20A, frequency 40Hz ) in a graphite crucible, and after Cu and Ni are melted, add 1.5Kg of electrolytic aluminum ingot with a purity of 99.95% for melting;

[0040] (2) Refining of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com