Quaternization lignin-base dispersing agent and preparation process and application thereof

The technology of a lignin-based, quaternary ammonium reagent is applied in the fields of environment-friendly materials, dispersants, and fine chemicals, which can solve the problems of inability to change the surface activity of lignosulfonates and high prices, and achieves easy availability of production raw materials and low cost. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

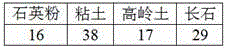

[0062] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0063] Pulping black liquor (wheat straw, Achnatherum splendens, eucalyptus pulp black liquor mixture, mass ratio 3:2:2, solid content 58%): 540.0 kg;

[0064] Sulfamic acid: 52.2 kg;

[0065] Benzoic acid: 16.0 kg;

[0066] Phenol: 34.8 kg;

[0067] Formaldehyde: 53.9 kg;

[0068] Sodium sulfite: 76.3 kg;

[0069] 1-Chloro-2 hydroxypropyltrimethylammonium chloride: 86.3 kg;

[0070] Water: 140.5 kg.

[0071] 2. Preparation process steps and parameters:

[0072] Into the reactor, add 16.0 kg of benzoic acid and 34.8 kg of phenol and 53.9 kg of formaldehyde at 100°C for 0.5 h, add 540.0 kg of pulping black liquor with a solid content of 58%, and heat up to 40°C, add 52.2 kg of sulfamic acid, and adjust the pH value of the reaction system to 12.0, add 76.3 kg of sodium sulfite to react at 110°C for 3 hours, then add 86.3 kg of 1-chloro-2-hydroxypropyl The trimethylammonium ch...

Embodiment 2

[0074] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0075] Pulping black liquor (rice straw, birch, masson pine kraft pulping black liquor mixture, mass ratio 3:2:1, solid content 50%): 495.3 kg;

[0076] p-Sulfuran: 41.3 kg;

[0077] Benzoic acid: 30.0 kg;

[0078] Phenol: 75.0 kg;

[0079] Acetaldehyde: 26.4 kg;

[0080] Sodium bisulfite: 150.0 kg;

[0081] Lauryl dimethyl benzyl ammonium chloride: 22.5 kg;

[0082] Water: 159.5 kg.

[0083] 2. Preparation process steps and parameters:

[0084] In the reactor, add successively 30.0 kilograms of benzoic acid and 75.0 kilograms of phenol, and 26.4 kilograms of acetaldehyde at 90°C for 1 hour, then add 495.3 kilograms of pulping black liquor with a solid content of 58%, and heat up to 60°C, add 41.3 kg of p-aminobenzenesulfonic acid, adjust the pH value of the reaction system to 11.0, add 150.0 kg of sodium bisulfite to react at 90°C for 2 hours, and then add 22.5 kg of dodecy...

Embodiment 3

[0086] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0087] Pulping black liquor (mixture of bamboo, bagasse, and awn stem pulping black liquor, the mass ratio is 7:2:1, and the solid content is 60%): 458.8 kg;

[0088] Amethanesulfonic acid: 45.9 kg;

[0089] Benzoic acid: 4.5 kg;

[0090] Phenol: 8.0 kg;

[0091] Acrolein: 10.0 kg;

[0092] Sodium metabisulfite: 25.0 kg;

[0093] Octadecyl dimethyl hydroxyethyl ammonium nitrate: 40.0 kg;

[0094] Water: 407.8 kg.

[0095] 2. Preparation process steps and parameters:

[0096]Add 4.5 kg of benzoic acid, 8.0 kg of phenol, and 10.0 kg of acrolein to the reactor in sequence, react at 85°C for 1.5 hours, then add 458.8 kg of pulping black liquor with a solid content of 60%, and raise the temperature to 30°C, add 45.9 kg of aminomethanesulfonic acid, and adjust the pH value of the reaction system to 13.0, add 25.0 kg of sodium metabisulfite to react at 110°C for 2.5 hours, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com