Normal-temperature quick-drying aqueous hydroxy acrylic resin and its preparation method and application

A hydroxy acrylic, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve the effect of improving vividness, low cost and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

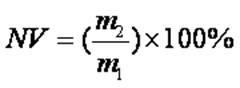

Image

Examples

Embodiment 1

[0078] Example 1 - Product Example

[0079] In the reactor equipped with stirring paddle, thermometer and condenser, add 45 parts by weight of dipropylene glycol monomethyl ether, feed nitrogen to raise the temperature to reflux temperature; add 12 parts by weight of methyl methacrylate dropwise at this temperature , 21 parts by weight of hydroxyethyl methacrylate, 5 to 10 parts by weight of methacrylic acid, 1 to 15 parts by weight of styrene, 1 part by weight of azobisisobutyronitrile and 0.5 parts by weight of mercaptoethanol The mixed solution is added dropwise within 4 hours, kept warm for 0.5~1h, then added 1 part by weight of azobisisobutyronitrile, kept warm for 2h, to obtain the acrylic resin prepolymer; the hydroxyl group obtained in the above step A Part of the solvent is removed by vacuum distillation of the acrylic resin, so that the content of the solvent in the resin is 5%. up to 80%, the neutralization reaction is carried out at 2500r / min under the high-speed ...

Embodiment 2

[0080] Example 2 - Use of the product (application example)

[0081] Get the water-based hydroxyacrylic resin prepared in Example 1, add leveling agent, defoamer, water, pigment, multifunctional auxiliary agent and optional thickener to it, obtain component A, wherein the addition of each component The amount is as follows (100 parts by weight of water-based hydroxyacrylic resin):

[0082] Waterborne hydroxy acrylic resin: 100

[0083] Leveling agent (BYK346 from BYK): 1~5

[0084] Defoamer (BYK028 from BYK): 0.2~1, preferably 0.2~0.6

[0085] Thickener (Borchi Gel PW-25 from Borchers, Germany): 0~0.8, preferably 0.2~0.5

[0086] Pigment (imported rutile titanium dioxide (after mixing, grind to a fineness of 10 microns)): 0~75, preferably 10~74

[0087] Multifunctional additives (BYK’s BYK 191 water-based dispersant, BYK’s BYK WS leveling agent, BYK’s BYK 022 defoamer, BYK’s 0622 polyurethane thickener, propylene glycol methyl ether acetate PMA co-solvent, BCS anti-white ...

Embodiment 7

[0092] Same as Example 6, except that the leveling agent addition in component A is 3 parts by weight of the water-based hydroxyacrylic resin weight, the defoamer addition is 0.4 parts by weight, no thickener is added, and the multifunctional auxiliary agent addition is 0.5 parts by weight, the added amount of water is 45 parts by weight, the ratio of component A to component B is A:B=1.5:1, and the added amount of pigment is 0 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com