A kind of offset printing ink resin

A technology of offset printing ink and resin, which is applied in the field of ink resin, can solve difficult problems, and achieve the effects of high viscoelasticity, good pigment wettability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

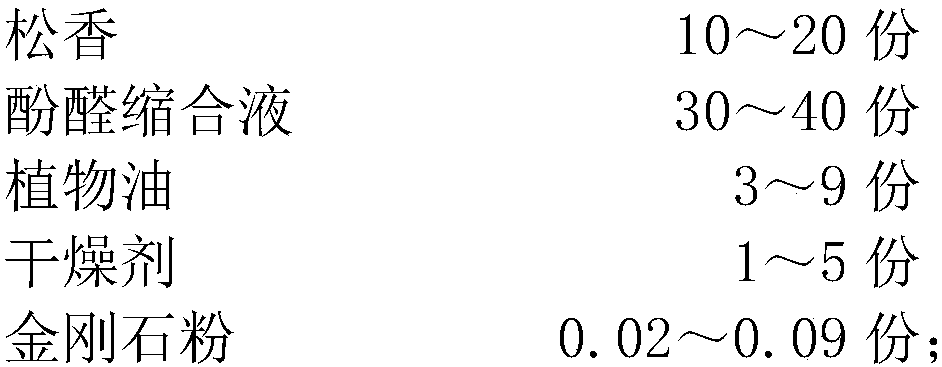

[0026] 1) Take the raw material by the following parts by weight:

[0027]

[0028] 2) Add the proportioned amount of rosin into the microwave reactor, adjust the microwave power to 480W, and keep it warm for 10 minutes until it completely melts;

[0029] 3) Add phenolic condensation solution, mix and stir evenly with the melted rosin in step 2), adjust the microwave power to 530W, and keep warm for 25 minutes;

[0030] 4) Continue to add desiccant and vegetable oil, adjust the microwave power to 530W, and keep it for 10 minutes;

[0031] 5) Finally, add diamond powder, stir mechanically for 20 minutes, take out the product, and dry it in vacuum.

[0032] The above desiccant is a mixture of 20 parts by weight of starch, 5 parts by weight of methylcellulose and 5 parts by weight of calcium chloride.

[0033] The above-mentioned vegetable oil is a mixture of 20 parts by weight of linseed oil and 20 parts by weight of soybean oil.

[0034] The preparation method of above-me...

Embodiment 2

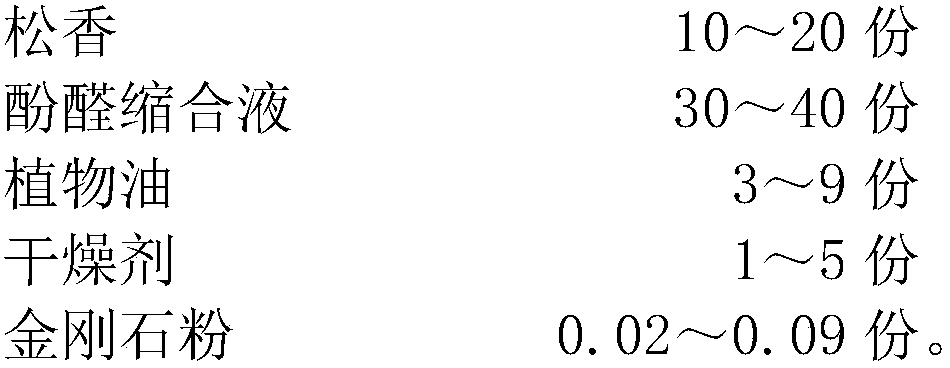

[0038] 1) Take the raw material by the following parts by weight:

[0039]

[0040] 2) Add the proportioned amount of rosin into the microwave reactor, adjust the microwave power to 470W, and keep it warm for 13 minutes until it completely melts;

[0041] 3) Add phenolic condensation solution, mix and stir evenly with the melted rosin in step 2), adjust the microwave power to 535W, and keep warm for 22 minutes;

[0042] 4) Continue to add desiccant and vegetable oil, adjust the microwave power to 540W, and keep it for 8 minutes;

[0043] 5) Finally, add diamond powder, stir mechanically for 22 minutes, take out the product, and dry it in vacuum.

[0044] The above desiccant is a mixture of 17 parts by weight of starch, 6 parts by weight of methylcellulose and 6 parts by weight of calcium chloride.

[0045] The above-mentioned vegetable oil is a mixture of 22 parts by weight of linseed oil and 18 parts by weight of soybean oil.

[0046] The preparation method of above-men...

Embodiment 3

[0050] 1) Take the raw material by the following parts by weight:

[0051]

[0052] 2) Add the proportioned amount of rosin into the microwave reactor, adjust the microwave power to 465W, and keep it warm for 15 minutes until it completely melts;

[0053] 3) Add phenolic condensation liquid, mix and stir evenly with the melted rosin in step 2), adjust the microwave power to 545W, and keep warm for 20 minutes;

[0054] 4) Continue to add desiccant and vegetable oil, adjust the microwave power to 545W, and keep it for 7 minutes;

[0055] 5) Finally, add diamond powder, stir mechanically for 25 minutes, take out the product, and dry it in vacuum.

[0056] The above desiccant is a mixture of 15 parts by weight of starch, 7 parts by weight of methylcellulose and 7 parts by weight of calcium chloride.

[0057] The above-mentioned vegetable oil is a mixture of 25 parts by weight of linseed oil and 15 parts by weight of soybean oil.

[0058] The preparation method of above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com