Positioning device for X-ray testing equipment

A technology of detection equipment and positioning device, which is applied in the direction of using radiation for material analysis, etc., can solve the problems of damage to the equipment to be tested, the weight of the X-ray machine, the large volume, and the narrow space, and achieves increased height difference, low cost, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

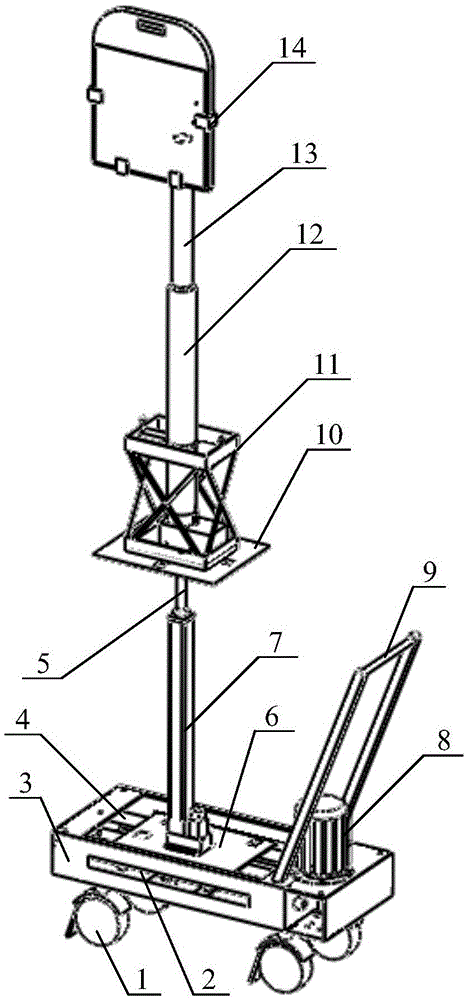

[0030] Such as figure 1 As shown, the positioning device of the present invention includes a base 3, a supporting platform 6 arranged on the base 3, a lifting device arranged on the supporting platform and a clamping part arranged on the lifting device, and the clamping part is used to install X For X-ray detection equipment, the lifting device can be raised and lowered so as to adjust the height of the X-ray detection equipment.

[0031] Specifically, the left and right sides of the base 3 are provided with slots 2 that match the support platform 6, and the left and right ends of the support platform 6 are respectively installed in the slots 2 on the left and right sides of the base 3, And the support platform 6 can slide in the slot 2 . Meanwhile, the base 3 is provided with a slide rail 4 on the lower side of the support platform 6 , and the support platform 6 is located on the slide rail 4 and can slide on the slide rail 4 . Because the X-ray machine is bulky and heavy, ...

Embodiment 2

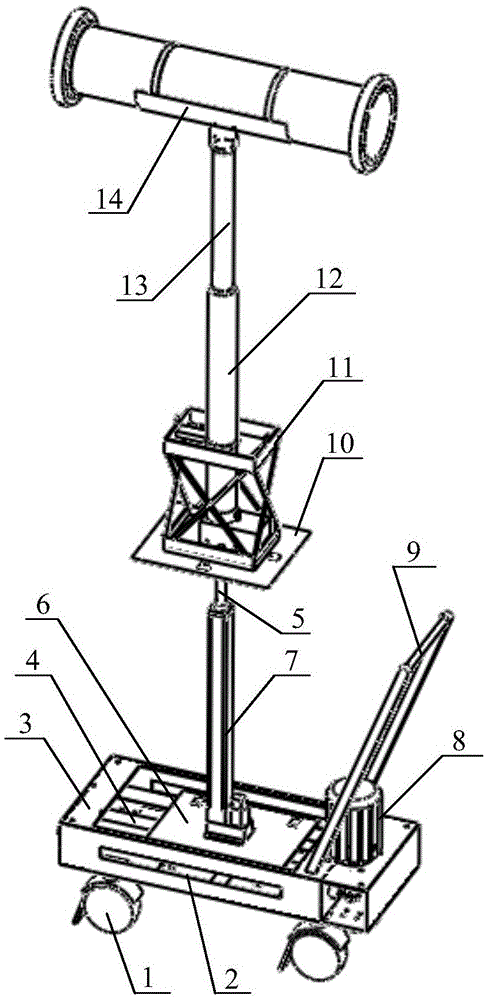

[0036] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the clamping part is the clamping plate 15 for installing the X-ray machine, and the clamping plate 15 is arranged on the top of the second elevating rod 13 . During use, also can use rope such as steel wire rope to fix the ray machine, in case the ray machine rotates. Specifically, use one end of the rope to be fixed on the fixed frame, fix the other end of the rope to one end of the ray machine, and use another rope to fix the other end of the ray machine in the same way, and then raise the second elevating rod 13, so that The two ends of the ray machine can be fixed by the rope when the rope is tightened.

[0037] The positioning device of the present invention can be used to install the imaging board and the X-ray machine at the same time. When installing the imaging board, you only need to select the jaws 14 and the rotating part for clamping the imaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com