Detection sampling device for petroleum fermentation treatment

A technology of petroleum fermentation and sampling devices, which is applied in the direction of sampling devices, measuring devices, sampling, etc., can solve the problems of incomplete sampling, affecting accuracy, and microbial entry, etc., and achieve the effect of fast fixing and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

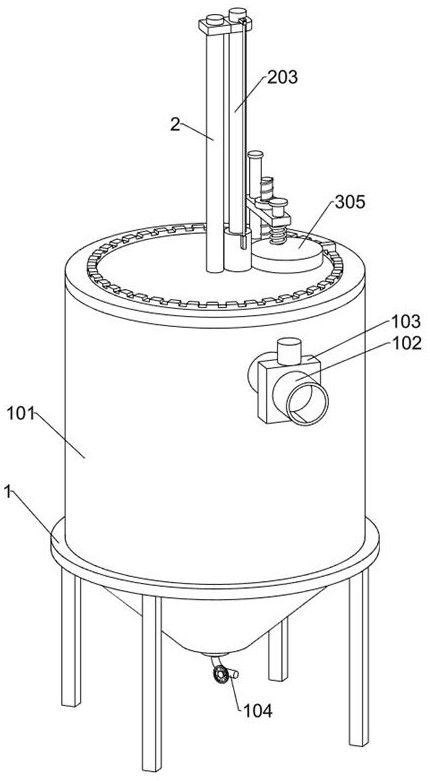

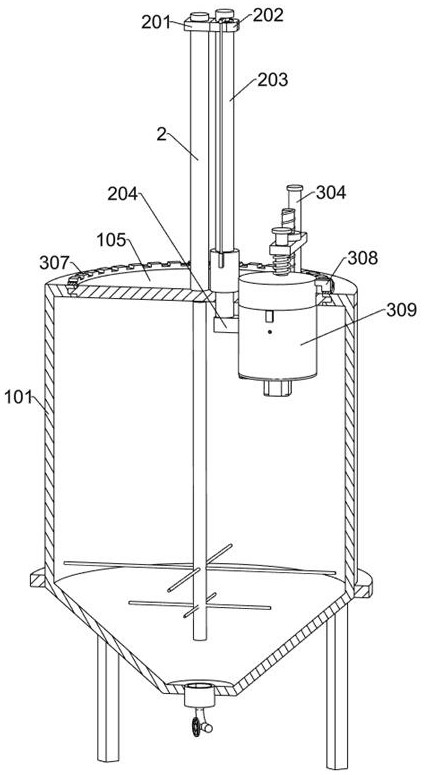

[0033] A detection and sampling device for petroleum fermentation treatment, such as figure 1 with figure 2 As shown, it includes a support 1, a tank body 101, a feed pipe 102, a solenoid valve 103, a discharge pipe 104, a first turntable 105, a telescoping mechanism, a sealing mechanism, a sampling mechanism, an overturning mechanism, a fixing mechanism, a collecting mechanism and To open the mechanism, a tank body 101 is fixedly connected to the support 1, a feed pipe 102 is communicated with the front side wall of the tank body 101, a solenoid valve 103 is arranged on the feed pipe 102, and a discharge pipe 104 is fixedly connected to the lower end of the tank body 101. The discharge pipe 104 is provided with a ball valve, and the upper end of the tank body 101 is rotated with a first turntable 105 for sampling the petroleum fermentation liquid in different regions. The right part of the telescopic mechanism is provided with a sealing mechanism, which is used to isolate t...

Embodiment 2

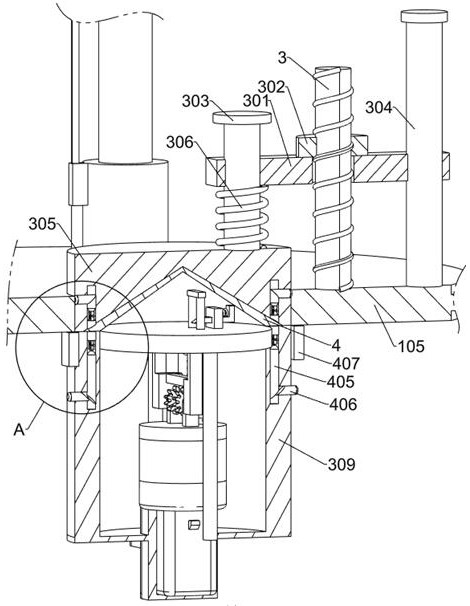

[0037] On the basis of Example 1, such as figure 2 with image 3 As shown, the sealing mechanism includes a threaded post 3, a first slider 301, a threaded block 302, a first guide post 303, a second guide post 304, a cover 305, a first spring 306, a serrated ring 307 and a block 308, The upper surface of the right part of the first turntable 105 is fixedly connected with a threaded column 3 and a second guide column 304, the second guide column 304 is slidably provided with a first slider 301, the middle part of the first slider 301 is provided with a through hole, and the threaded column 3 Located in the through hole of the first slider 301, the diameter of the through hole of the first slider 301 is larger than the diameter of the threaded post 3, the threaded post 3 is threaded with a threaded block 302, the threaded block 302 is located above the first slider 301, the second A sliding block 301 front is provided with a first guide post 303, the bottom of the first guide...

Embodiment 3

[0048] On the basis of Example 2, such as figure 2 As shown, the telescopic mechanism includes an electric slide rail 2, an electric slide block 201, a first fixed block 202, a sliding rod 203, and a second fixed block 204. 2 The upper end is slidably provided with an electric slider 201, and the right end of the electric slider 201 is fixedly connected with a first fixed block 202, and the first fixed block 202 is fixedly connected with the upper part of the sliding rod 203, and the upper part of the sliding rod 203 is provided with an arc-shaped groove for sliding The arc-shaped groove of the rod 203 is located above the first fixed block 202, the lower part of the sliding rod 203 penetrates the first turntable 105, and the lower end of the sliding rod 203 is fixedly connected with the second fixed block 204, which is used to place the sampling mechanism in different positions of the petroleum fermentation liquid. high.

[0049] Such as Figure 11 with Figure 12 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com