Underground coal mine multipurpose overall crawler type full-hydraulic directional drilling machine

A directional drilling rig, multi-purpose technology, applied in directional drilling, drilling equipment, earthwork drilling and mining, etc., can solve the problems of small spindle angle adjustment range, poor process adaptability, inconvenient installation and use of explosion-proof computer, etc., to improve construction adaptability , High drilling efficiency, simple and elegant appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

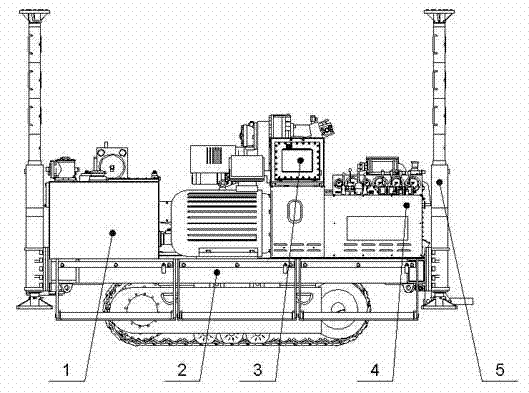

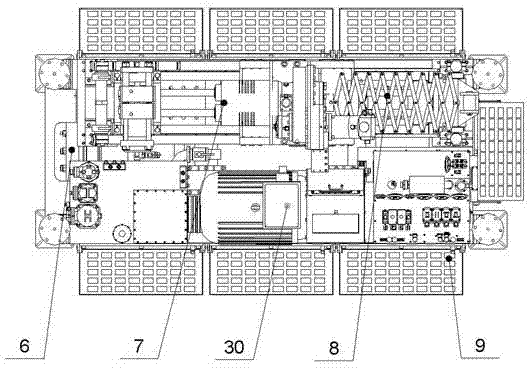

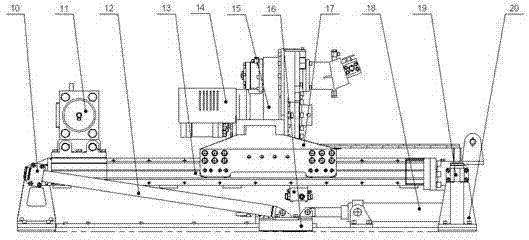

[0024] see figure 1 and figure 2 Its structure of the present invention comprises main engine 7, explosion-proof computer group 3, fuel tank 1, console 4, crawler car body platform 2, cooler 6, stable oil cylinder 5, oil cylinder telescopic protection 8, operating pedal 9, motor pump group 30, described The main engine 7 is arranged on the right side of the crawler body platform 2; the fuel tank 1, the motor pump unit 30 and the console 4 are arranged on the left side of the car body platform 2; side, the cooler 6 is installed on the front side of the crawler body platform 2; the operation platform 9 is installed on both sides and the rear side of the crawler body platform 2, and can be turned over 90° for storage, and is positioned by a latch. It is convenient for the driller to observe the hole situation and control the drilling rig and the explosion-proof pen computer 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com