Construction method of cast-in-place pile passing through karst cave

A construction method and cast-in-place pile technology, which are applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of easy collapse of the cave roof, difficult pouring of concrete, and difficulty in foundation construction, so as to prevent cave collapse and enhance construction adaptability. , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

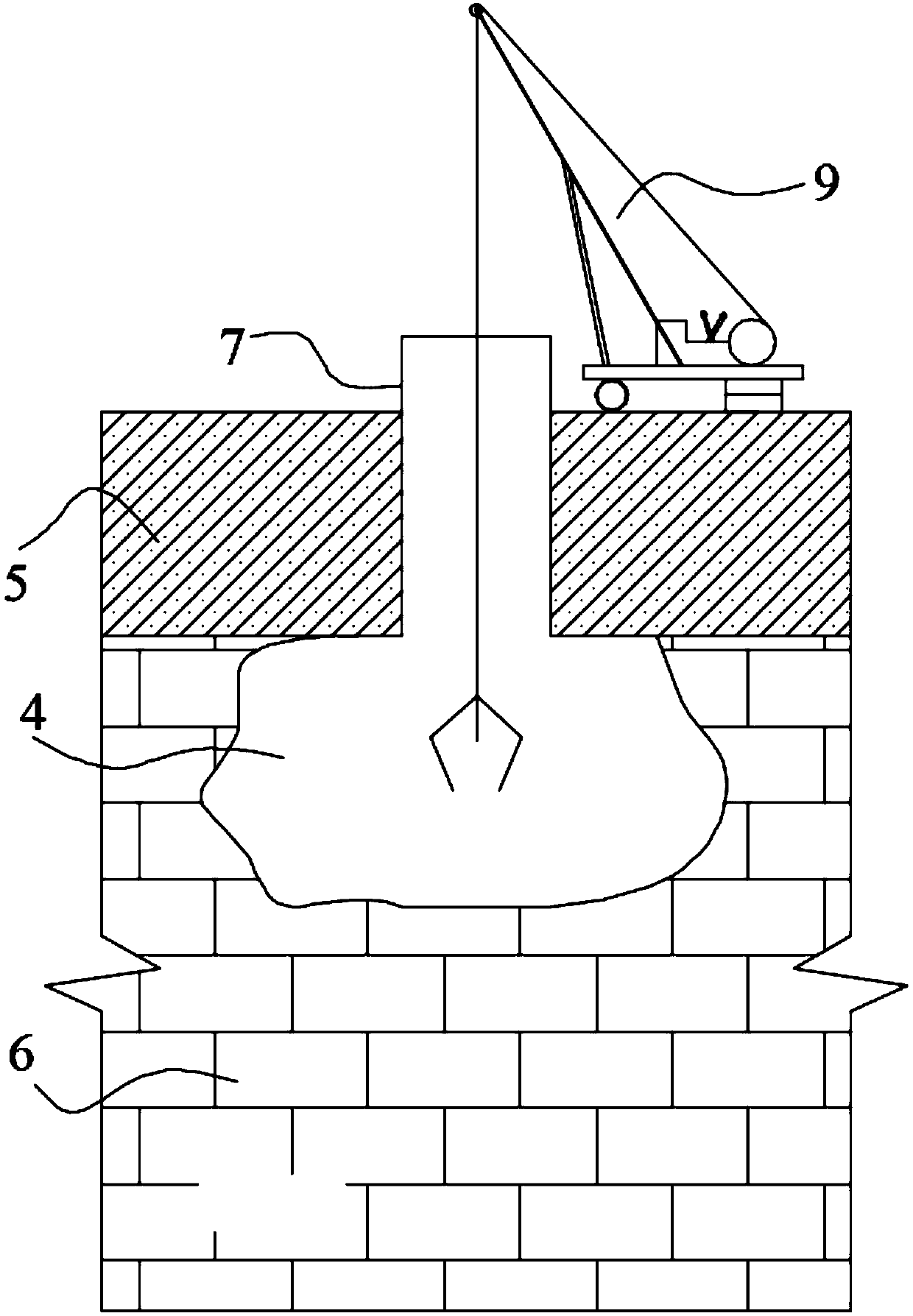

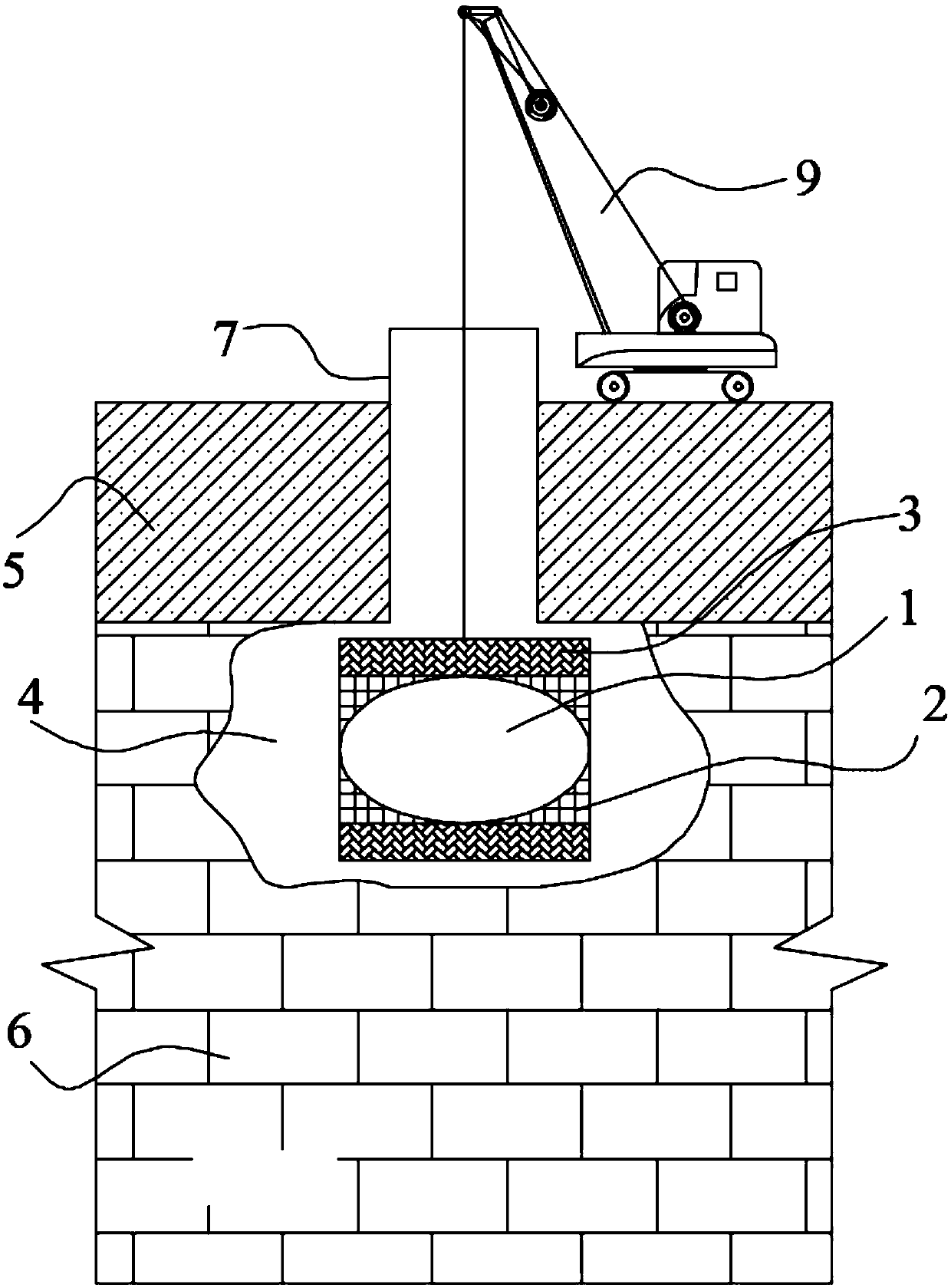

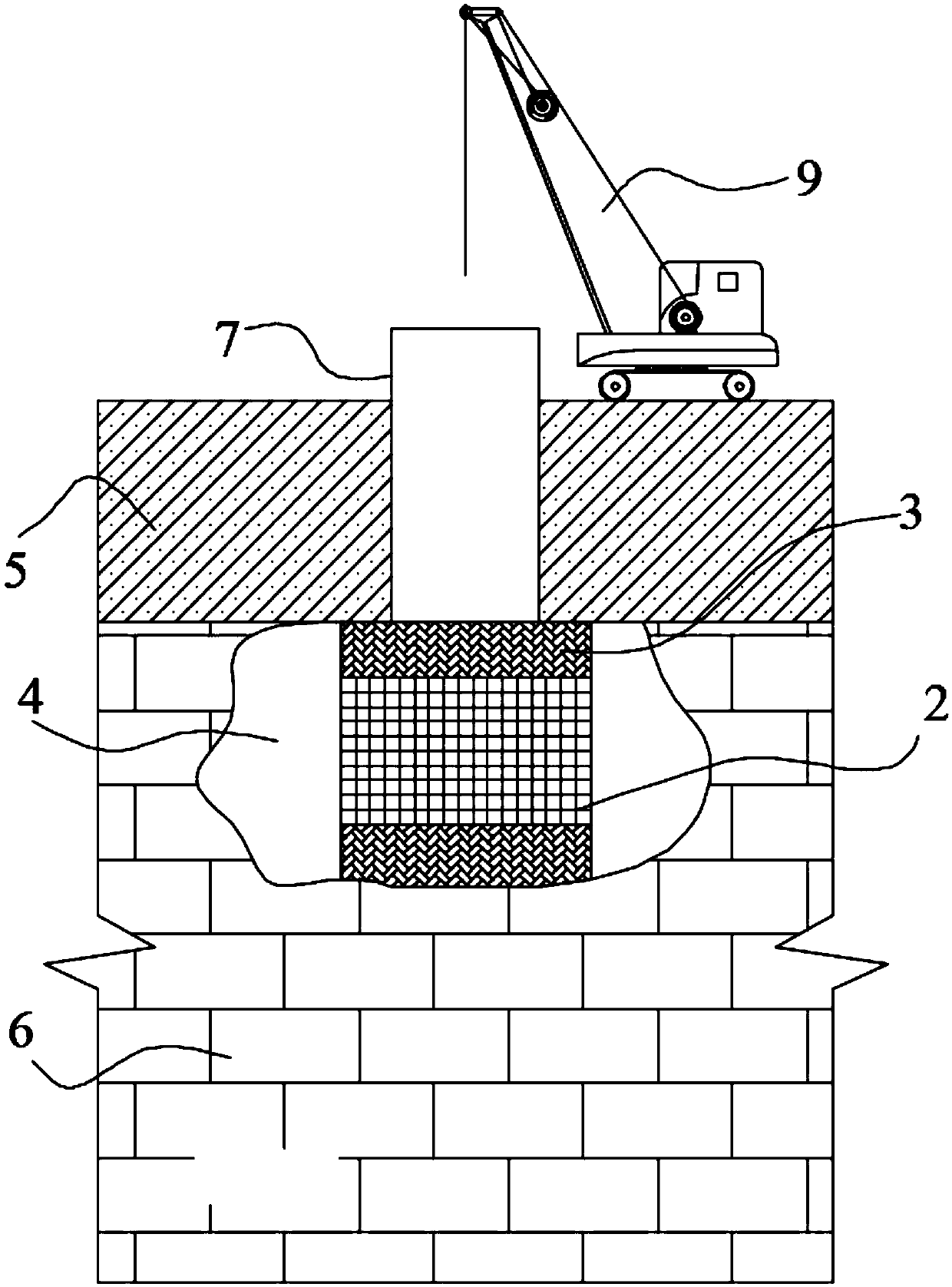

[0037] The mode and implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] Such as Figure 7 and Figure 8 As shown, a pile foundation construction enclosure structure includes a plurality of steel wire meshes and a super-strong geotextile 2.2, and the multi-piece steel wire meshes are sequentially hinged end to end to form an expandable enclosure device 2, and the super-strong geotextile 2.2 Cover the expandable containment device 2 to provide binding force for the expandable containment device 2 and prevent pouring concrete from leaking out. The steel wire mesh is low-carbon steel wire mesh 2.1, which has high strength , high corrosion resistance, high rigidity, and a certain self-stabilization ability to ensure that it will not fall like the inside; low-carbon steel wire mesh 2.1 is covered with super-strong geotextile 2.2 outside, which can ensure the enclosure capacity of the steel wire mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com