Single component air-drying water-based rust inhibiting primer with curtaining capacity and used for electrical equipment housing as well as preparation method of primer

A technology for electrical equipment and anti-rust primers, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor performance, hinder the promotion of water-based coating products, and cannot use the curtain coating process, and achieve strong construction. The effect of adaptability, short construction interval and good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

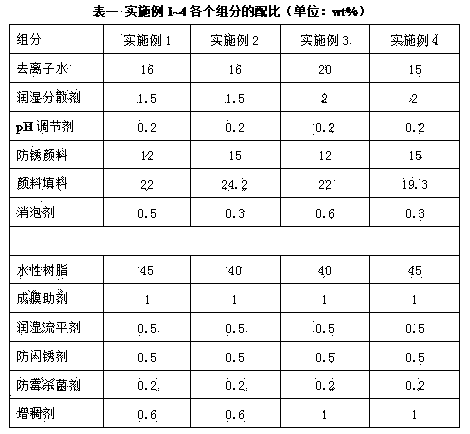

Embodiment 1

[0044] (1) Preparation of water-based color paste: Combine all deionized water, wetting and dispersing agent TEGO-760w, pH regulator 2-amino-2-methyl-1-propanol (AMP95) and 1 / 3 defoamer Add TEGO-901w into the stirring tank, stir at 1500~2500rpm / min for 10~20 minutes, after the dispersion is uniform, add the antirust pigment domestic zinc phosphate (HT-12), zinc silicate mixture (SZP- 391), aluminum tripolyphosphate (APW-Ⅱ), water molecule barrier, composite iron titanium powder (808), pigment filler precipitated barium sulfate, talc, ceramic beads and the remaining defoamer TEGO-901w, after uniform dispersion Transfer to a sand mill, grind at 3000~5000 rpm / min for 1~3 hours until the slurry fineness is less than or equal to 25 microns, then add mica iron oxide red and mica powder at a speed of 2500~3500 rpm / Disperse at high speed for 25~35min to obtain water-based color paste;

[0045] (2) Preparation of water-based anti-rust primer: Add water-based acrylate emulsion MC-105 and...

Embodiment 2

[0047] (1) Preparation of water-based color paste: Combine all deionized water, wetting and dispersing agent TEGO-760w, pH regulator 2-amino-2-methyl-1-propanol (AMP95) and 1 / 3 defoamer Add TEGO-901w into the stirring tank, stir at 1500~2500rpm / min for 10~20 minutes, after the dispersion is uniform, add the anti-rust pigment imported zinc phosphate (Nubirox N2) and aluminum tripolyphosphate (APW-Ⅱ) under stirring conditions ), the pigment filler precipitated barium sulfate, calcium carbonate and the remaining defoamer TEGO-901w, dispersed uniformly, transferred to a sand mill, grind at 3000~5000 rpm / min for 1~3 hours until the slurry fineness is less than or It is equal to 25 microns, then add the anti-rust pigment zinc aluminum phosphate (ZPA) and pigment filler mica iron oxide red, mica powder and glass powder, and disperse at a high speed of 2500~3500 rpm / min for 25~35min to obtain water-based color paste;

[0048] (2) Preparation of water-based anti-rust primer: Add water-bas...

Embodiment 3

[0050] (1) Preparation of water-based color paste: combine all deionized water, wetting and dispersing agent Dispersogen DIP, pH regulator 2-amino-2-methyl-1-propanol (AMP95) and 1 / 3 of defoamer TEGO -810 is added to the stirring tank, stirred at 1000~1500rpm / min for 10~20 minutes, and dispersed evenly. Under stirring conditions, add imported zinc phosphate (Nubirox N2) and aluminum tripolyphosphate (APW-Ⅱ), Pigment filler precipitates barium sulfate, calcium carbonate and the remaining defoamer TEGO-810, dispersed uniformly, transfer to sand mill, grind at 3000~5000 rpm / min for 1~3 hours to grind to slurry fineness less than Or equal to 25 microns, then add anti-rust pigment zinc aluminum phosphate (ZPA), pigment filler mica iron oxide red, glass powder, and disperse at a high speed of 2500~3500 rpm / min for 25~35min to obtain a water-based anti-rust color paste;

[0051] (2) Preparation of water-based anti-rust primer: Add water-based acrylate emulsion Antkote-0618, film-forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com