Oil separation prime coat for long-acting anti-corrosion system and preparation method thereof

A long-term anti-corrosion and production method technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of anti-corrosion components leakage, corrosion, and mold growth on the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

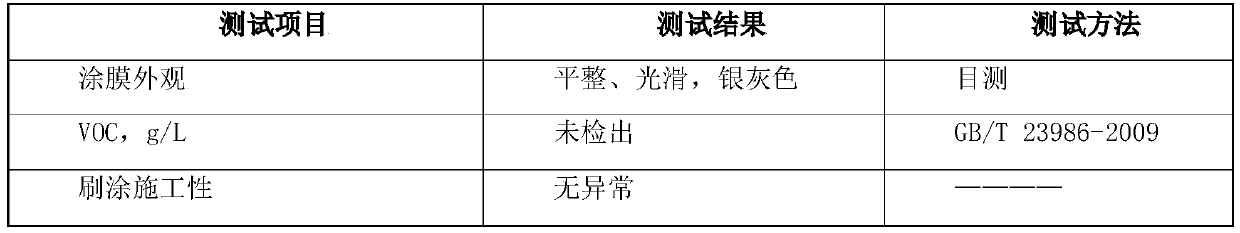

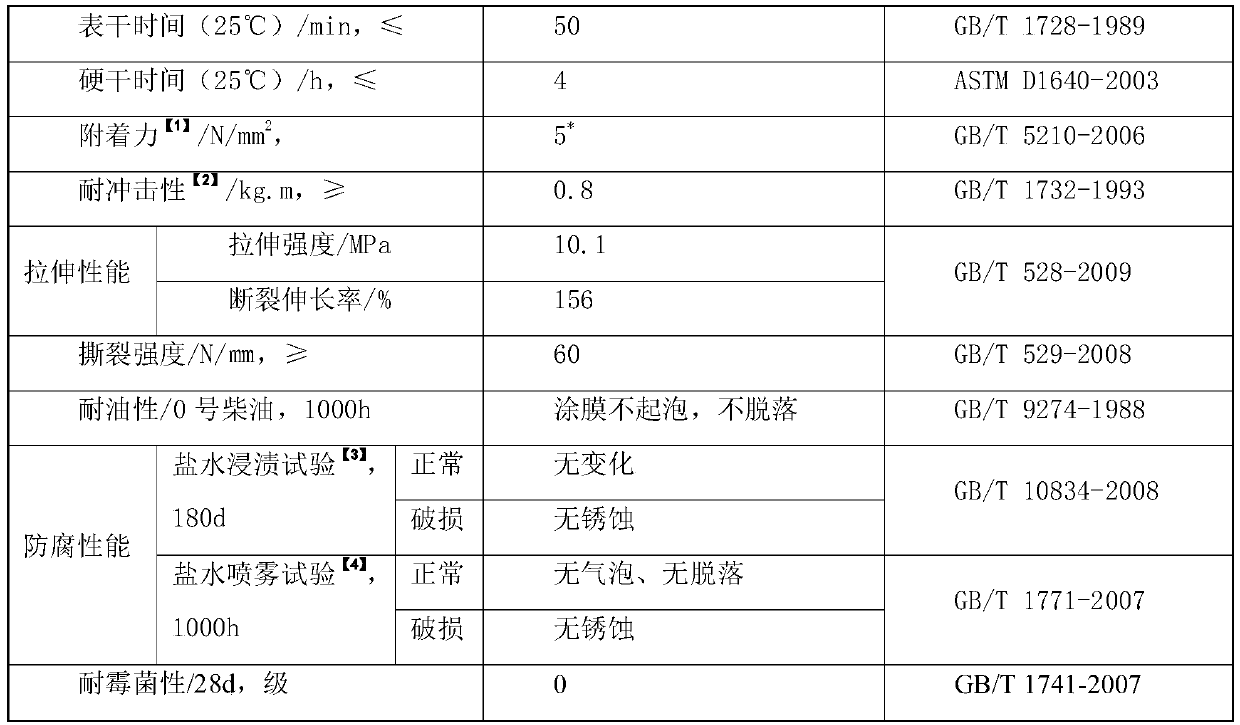

Embodiment 1

[0027]The first embodiment of the present invention provides an oil-separating primer for long-acting anti-corrosion systems, which is applied to the surface of the anti-corrosion belt layer and the steel surface of the extension part, so that it can be closely combined with the surface of the soft anti-corrosion belt, and at the same time It also has strong adhesion to the steel surface. In addition, in order to adapt to the complexity of multi-layer construction, the curing time of the oil-separating primer is extremely short, and the next process can be carried out within 2 to 3 hours, and it can be combined with the outer coating Layer or resin composite shell has excellent adaptability. After curing, it can completely seal the surface of the anti-corrosion tape, and the effect of anti-corrosion protection on the steel surface of the extension part of the anti-corrosion area is also outstanding. The coating film after completion is not easy to be damaged. Mold erosion can a...

Embodiment 2

[0053] Based on the same inventive concept, the embodiment 2 of the present invention provides a method for making an oil-separating primer for a long-acting anticorrosion system, the method for making the above-mentioned oil-separating primer, the Oil primer production methods include:

[0054] (1) Add liquid epoxy resin and polypropylene glycol diglycidyl ether into the planetary stirring reactor, turn on the planetary stirring reactor for stirring, slowly raise the temperature to 110°C during the stirring process, and control the temperature within the range of 110±5°C, After vacuum dehydration for 1-2 hours, cool to below 40°C to obtain polyether-terminated MDI prepolymer;

[0055] (2) Add pentaerythritol tetra-3-mercaptopropionate to the reaction kettle, start the planetary stirring reaction kettle to stir, slowly add the mixture of dehydrated liquid epoxy resin and polypropylene glycol diglycidyl ether during the stirring process, and slowly heat up to 90 ℃, control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com