Water reducing agent composition for coal mine paste filling and its preparation method and application

A paste filling and composition technology, which is applied in the field of paste filling, can solve the problems of poor slump-preserving effect of gangue gypsum filling materials, unsatisfactory application effect of water-reducing agent, unable to meet construction design requirements, etc., so as to improve the wrapping performance. and flow properties, rapid strength increase, and the effect of promoting water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

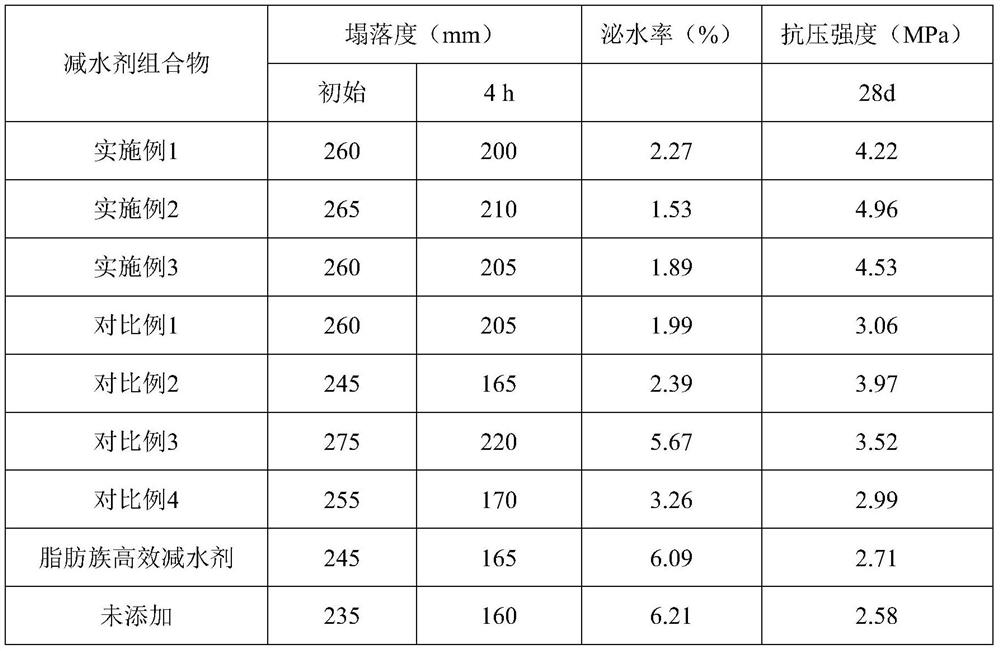

Examples

Embodiment 1

[0036] This embodiment provides a water-reducing agent composition for coal mine paste filling. The proportions of the components are as follows: aliphatic high-efficiency water-reducing agent 45%, reinforcing agent 5%, dispersant 0.2%, water-retaining agent 0.01% , the balance is water.

[0037] Specifically, the above-mentioned reinforcing agent is compounded by ethylene glycol and sodium thiosulfate decahydrate in a mass ratio of 1:9, the above-mentioned dispersing agent is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0038] The preparation method of this water reducing agent composition comprises the following steps:

[0039] Mix the components of the enhancer evenly,

[0040] The water in the prescribed amount is provided, and an aliphatic superplasticizer, a reinforcing agent, a dispersant, and a water-retaining agent are added in sequence, and the mixture is uniformly mixed to obtain the water-reducing agent composition.

Embodiment 2

[0042] This embodiment provides a water-reducing agent composition for coal mine paste filling. The proportions of the components are as follows: aliphatic superplasticizer 55%, reinforcing agent 9%, dispersant 0.4%, water-retaining agent 0.02% , the balance is water.

[0043] Specifically, the above-mentioned reinforcing agent is compounded by ethylene glycol and sodium thiosulfate decahydrate in a mass ratio of 1:9, the above-mentioned dispersing agent is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0044] The preparation method of this water reducing agent composition comprises the following steps:

[0045] Mix the components of the enhancer evenly,

[0046] The water in the prescribed amount is provided, and an aliphatic superplasticizer, a reinforcing agent, a dispersant, and a water-retaining agent are added in sequence, and the mixture is uniformly mixed to obtain the water-reducing agent composition.

Embodiment 3

[0048] This embodiment provides a water-reducing agent composition for coal mine paste filling. The proportions of the components are as follows: aliphatic superplasticizer 53%, reinforcing agent 6%, dispersant 0.3%, water-retaining agent 0.015% , the remainder is water.

[0049] Specifically, the above-mentioned reinforcing agent is compounded by ethylene glycol and sodium thiosulfate decahydrate in a mass ratio of 1:9, the above-mentioned dispersing agent is CPE1500, and the above-mentioned water-retaining agent is HPC.

[0050] The preparation method of this water reducing agent composition comprises the following steps:

[0051] Mix the components of the enhancer evenly,

[0052] The water in the prescribed amount is provided, and an aliphatic superplasticizer, a reinforcing agent, a dispersant, and a water-retaining agent are added in sequence, and the mixture is uniformly mixed to obtain the water-reducing agent composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com