A kind of pretreatment method of composite electrode for tempo/mv flow battery

A liquid flow battery and composite electrode technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of low electrochemical activity, poor conductivity, and low specific surface area, and achieve increased specific surface area, stable performance, and increased reaction area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

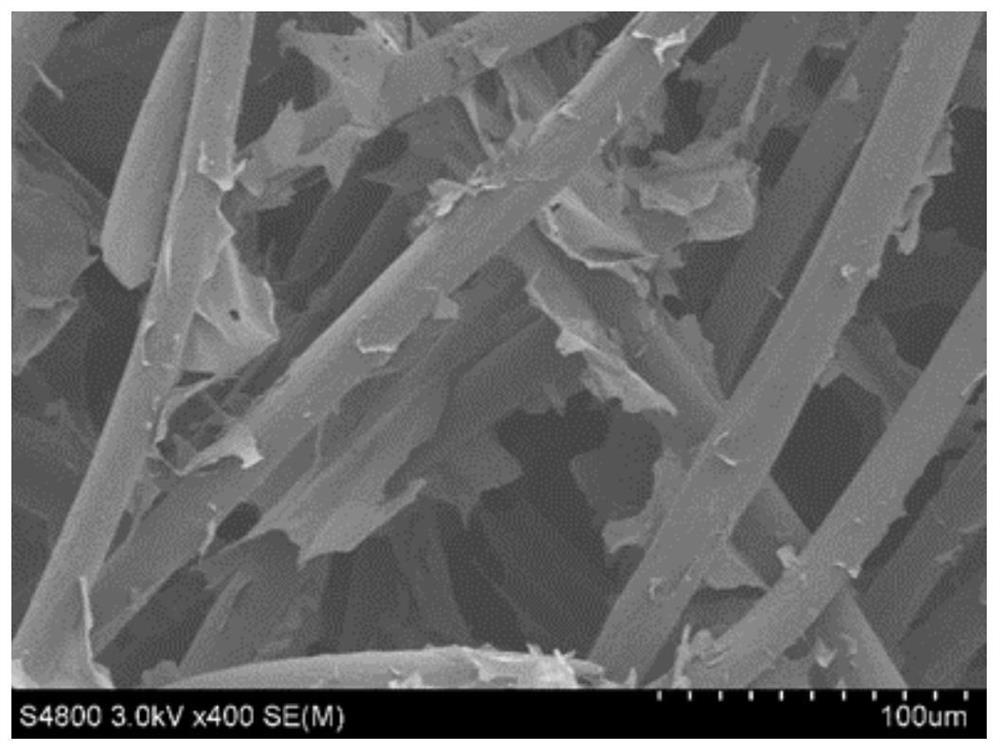

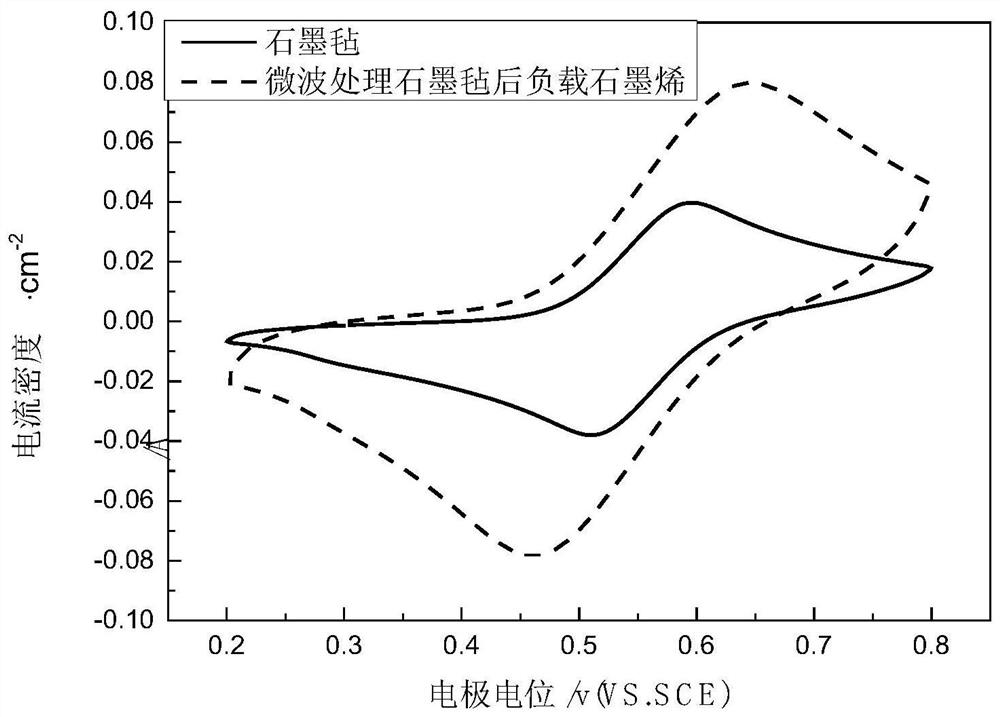

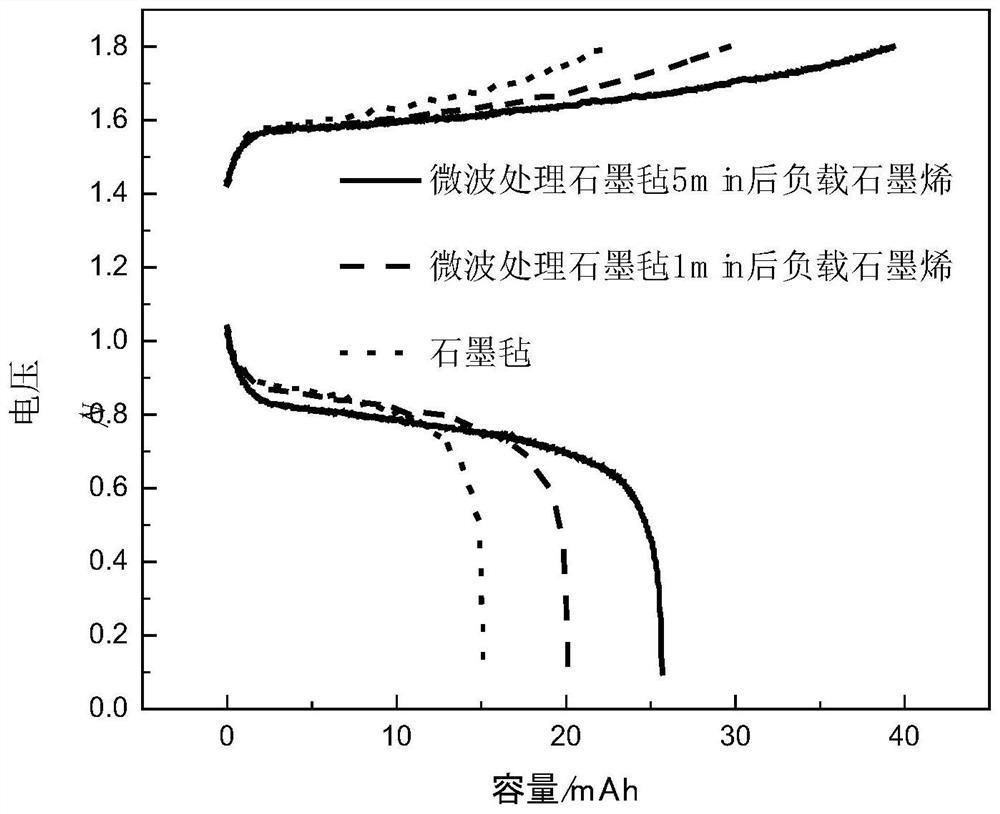

[0030] Heat a graphite felt electrode with a certain area in a 500W microwave oven for 1min, wash it with deionized water, and dry it in an oven at 80°C for 12h. Add 10ml of ethylenediamine to 50ml of deionized water, and completely immerse the dried graphite felt electrode in the aqueous solution of ethylenediamine. After 12 hours, put it into a hydrothermal reaction kettle containing 2mg / L graphene oxide and 10mL ethylenediamine solution, react at 180°C for 12 hours, and then cool to room temperature. Take out the graphite felt with three-dimensional graphene, put it into a freeze dryer and freeze-dry it for 24 hours to obtain the target electrode material. In order to test the electrochemical performance of the electrode, the electrode was assembled into a TEMPO / MV flow battery for charge and discharge tests. At a current density of 100mA / cm2, the voltage efficiency of the battery was 92%, and the energy efficiency was 95%.

Embodiment 2

[0032] Heat a graphite felt electrode with a certain area in a 500W microwave oven for 5min, wash it with deionized water, and dry it in an oven at 100°C for 6h. Add 8ml of ethylenediamine to 50ml of deionized water, and completely immerse the dried graphite felt electrode in the aqueous solution of ethylenediamine. After 10 hours, put it into a hydrothermal reaction kettle containing 2mg / L graphene oxide and 8mL ethylenediamine solution, react at 165°C for 15 hours, and then cool to room temperature. Take out the graphite felt with three-dimensional graphene, put it into a freeze dryer and freeze-dry it for 24 hours to obtain the target electrode material. In order to test the electrochemical performance of the electrode, the electrode was assembled into a TEMPO / MV flow battery for charge and discharge tests, at 150mA / cm 2 Under the current density, the voltage efficiency of the battery is 93%, and the energy efficiency is 94%.

Embodiment 3

[0034] Heat a carbon paper electrode with a certain area in a 500W microwave oven for 1min, wash it with deionized water, and dry it in an oven at 80°C for 6h. Add 4ml of ethylenediamine to 50ml of deionized water, and completely immerse the dried carbon paper electrode in the aqueous solution of ethylenediamine. After 6 hours, put it into a hydrothermal reaction kettle containing 2mg / L graphene oxide and 8mL ethylenediamine solution, react at 165°C for 15 hours, and then cool to room temperature. Take out the carbon paper electrode with three-dimensional graphene, and put it into a freeze dryer for 24 hours to freeze-dry to obtain the target electrode material. In order to test the electrochemical performance of the electrode, the electrode was assembled into a TEMPO / MV flow battery for charge and discharge tests, at 50mA / cm 2 Under the current density, the battery has a voltage efficiency of 90% and an energy efficiency of 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com