Excitation force control system and excitation force control method of intelligent steering vibratory roller

A technology of vibratory road roller and control method, applied in the direction of roads, roads, road repair, etc., can solve the problems of overpressure, low compaction efficiency, and single applicable occasions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

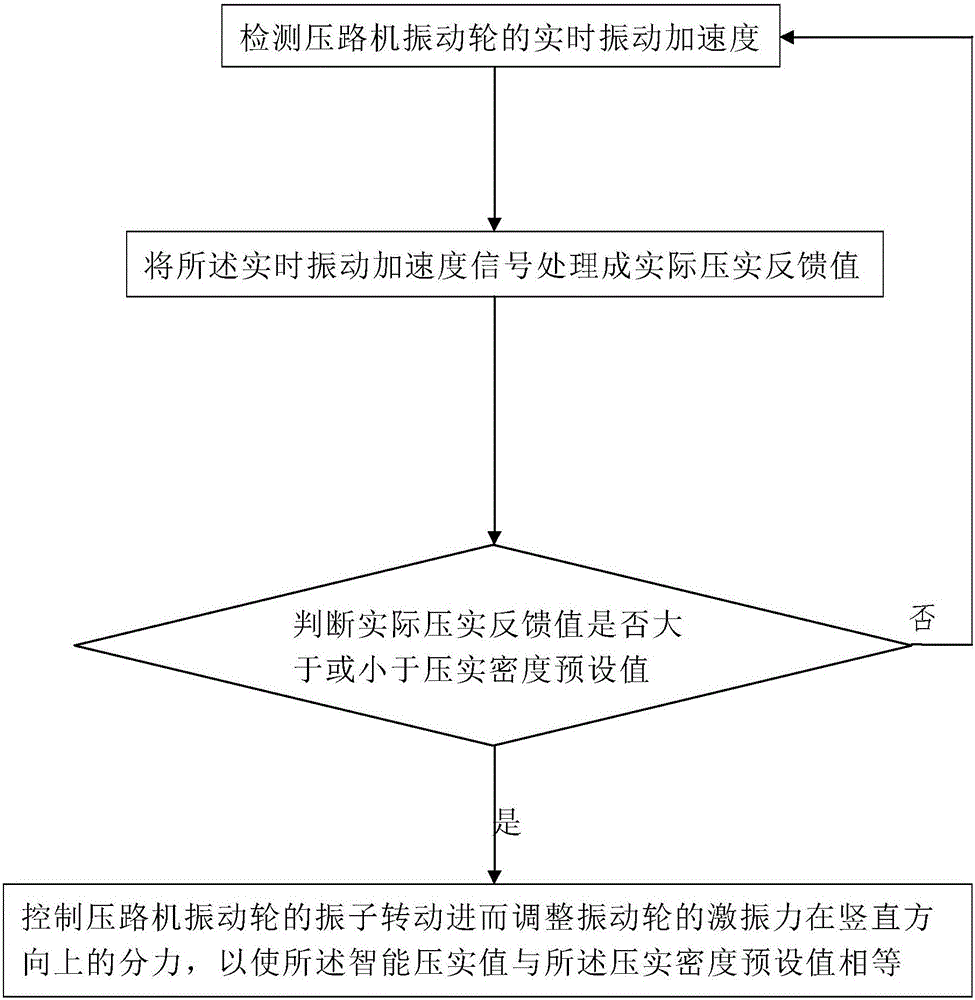

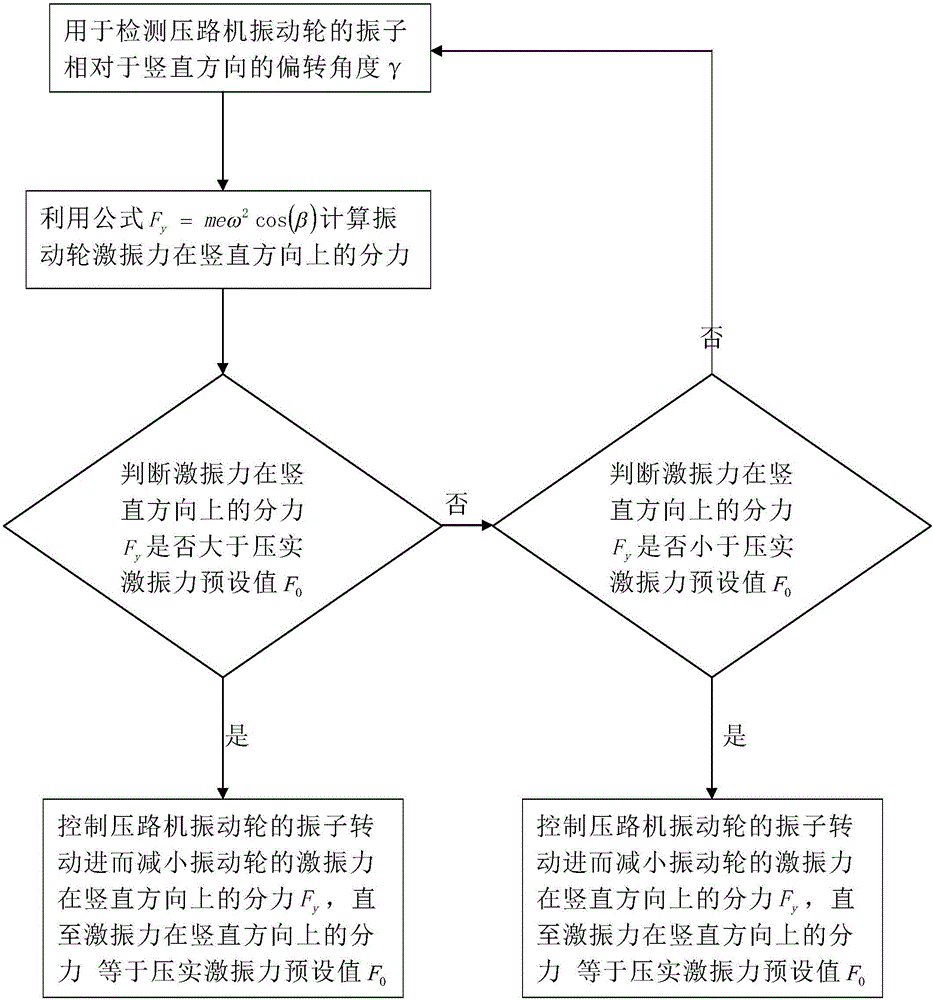

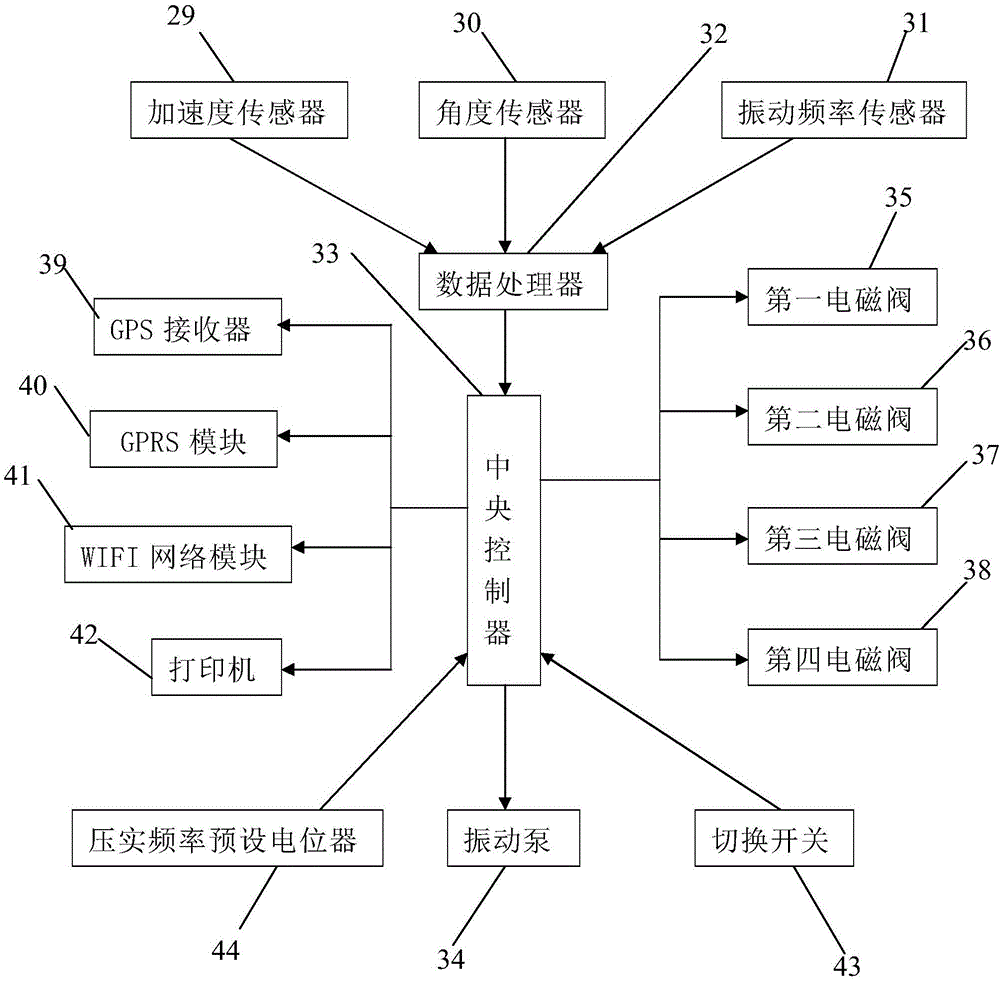

[0091] Such as figure 1 The shown method for controlling the exciting force of an intelligent direction-adjusting vibratory roller includes the following steps:

[0092] Step 1: Detect the real-time vibration acceleration of the vibrating wheel of the roller;

[0093] Step 2: Processing the real-time vibration acceleration signal into an actual compaction feedback value;

[0094] In this embodiment, in step 2, the specific method for processing the vibration acceleration signal into an actual compaction feedback value includes the following steps:

[0095] Step 201: Pass the formula g y (n)=g 1 cos(α)+g 2 cos(α) calculates two vibration acceleration signals g 1 And g 2 Value in the vertical direction, where g y (n) is the acceleration value in the vertical direction, α is the angle between the acceleration sensor used to detect the real-time acceleration signal and the vertical direction, in this embodiment, α=45°;

[0096] Step 202, to g y (n) Perform Fourier transform to obtain an arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com