HBSY-KL type temperature-inhibiting, anti-cracking, anti-corrosion and waterproof additive for concrete

A technology of concrete and additives, applied in the field of concrete admixtures, can solve the problems of not being able to improve the waterproof and anti-corrosion performance and mechanical strength of concrete, refine capillary gaps, and reduce the heat of hydration at the same time, so as to achieve good waterproof effect, simple feeding method, The effect of preventing erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

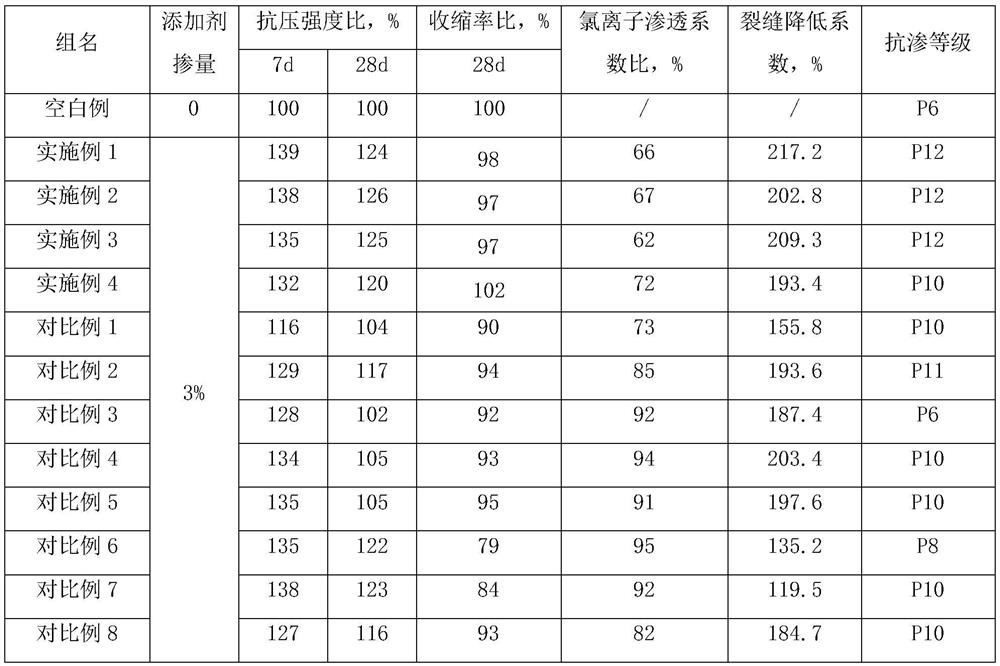

Examples

Embodiment 1

[0024] The HBSY-KL-001 type temperature-suppressing, anti-cracking, anti-corrosion, and waterproof additive for concrete provided in this embodiment includes the following raw materials in mass percentages: 2% of nano-calcium silicate hydrate crystal seeds, 3% of modified nano-silicon dioxide, polyethylene 2.5% diol, 1.5% citric acid, 0.5% modified polystyrene, 1.2% triisopropanolamine, 5% sodium metasilicate, 2% sodium hexametaphosphate, 0.7% boric acid ester coupling agent, remaining for water;

[0025]The preparation method of the nano-calcium silicate hydrate crystal seed is as follows: add uncalcined diatomite to the quicklime first, then add uncalcined diatomite, and the weight ratio of quicklime to non-calcined diatomite is 1:1 according to the respective active ingredient contents; Add water and stir to prepare a uniform solution; then boil the solution under normal pressure for 4 hours, add 0.5% aluminum sulfate with an amount of quicklime, and continue boiling for 1 ...

Embodiment 2

[0031] The HBSY-KL-001 type temperature-suppressing, anti-cracking, anti-corrosion, and waterproof additive for concrete provided in this example is basically the same as that of Example 1, except that the raw materials used include: 4% of nano-calcium silicate hydrate seed solution, Modified nano-silica 1%, polyethylene glycol 1.5%, sorbitol 0.5%, modified polystyrene 0.5%, triisopropanolamine 0.8%, sodium metasilicate 3%, sodium hexametaphosphate 5% , borate coupling agent 0.8%, the rest is water.

Embodiment 3

[0033] The HBSY-KL-001 type temperature-suppressing, anti-cracking, anti-corrosion, and waterproof additive for concrete provided in this example is basically the same as that of Example 1, except that the raw materials used include: 5% nano-calcium silicate hydrate seed crystals, modified Non-toxic nano silicon dioxide 5%, polyethylene glycol 1%, citric acid 0.5%, modified polystyrene 0.5%, triisopropanolamine 2%, sodium metasilicate 1%, sugar 2%, boric acid ester The coupling agent is 0.5%, and the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com