Preparation method of copper-iron alloy

A technology of copper-iron alloy and iron powder, applied in the field of preparation of copper-iron alloy, can solve the problems of difficulty in meeting high-strength copper-iron alloys, inability to prepare billets with uniform composition, poor wettability of Cu and Fe, etc., achieve uniform sintering shrinkage deformation, increase solid phase The effect of high diffusion rate and sintered relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

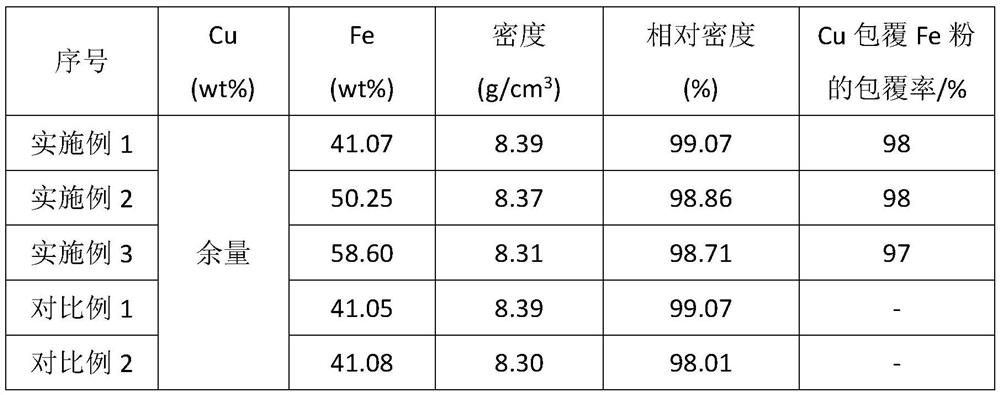

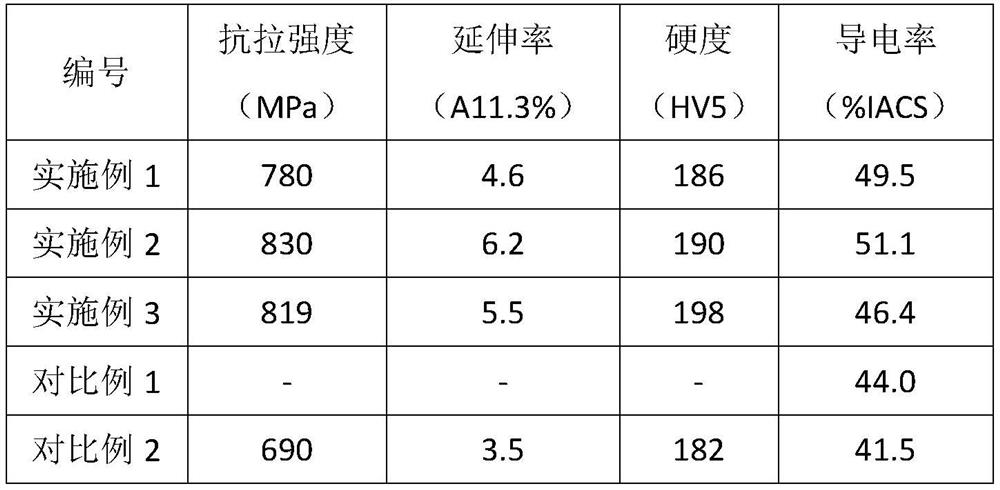

[0035] Example 1 and Example 3 were prepared by the method of the present invention, and the specific ingredients are shown in Table 1.

[0036] Example 1

[0037] The preparation steps of this copper-iron alloy:

[0038] 1) Preparation of Cu-coated Fe powder: According to the target composition, weigh iron powder and copper oxide powder for ball milling, the particle size ratio of iron powder and copper oxide powder is 20, and Fe powder is reduced iron powder, iron powder Particle size ≤ 2μm. The ball-to-material ratio is 5:1, the rotating speed is 300rpm, and the ball milling time is 30min to obtain the mixed powder;

[0039] The mixed powder was first reduced with hydrogen, the reduction temperature was 300°C, and the reduction time was 120 minutes; after the reduction, the temperature was continued to rise to 800°C, and the holding time was 5 hours to obtain Cu-coated Fe powder.

[0040] 2) Cold isostatic pressing: Encapsulate Cu-coated Fe powder in an elastic plastic m...

Embodiment 2

[0047] 1) Preparation of Cu-coated Fe powder: According to the target composition, weigh iron powder and copper oxide powder for ball milling, the particle size ratio of iron powder and copper oxide powder is 30, and Fe powder is reduced iron powder, iron powder Particle size ≤ 2μm. The ball-to-material ratio is 6:1, the rotating speed is 300rpm, and the ball milling time is 20min to obtain the mixed powder;

[0048] The mixed powder was first reduced with hydrogen, the reduction temperature was 250°C, and the reduction time was 80 minutes; after the reduction, the temperature was continued to rise to 750°C, and the holding time was 3 hours to obtain Cu-coated Fe powder.

[0049] 2) Cold isostatic pressing: Encapsulate Cu-coated Fe powder in an elastic rubber mold, seal it and put it into a high-pressure cylinder with a pressing force of 300MPa and a pressing time of 360s.

[0050] 3) Pre-sintering: pre-sintering the blank at 800° C. for 90 minutes in a hydrogen atmosphere. ...

Embodiment 3

[0056] 1) Preparation of Cu-coated Fe powder: According to the target composition, weigh iron powder and copper oxide powder for ball milling, the particle size ratio of iron powder and copper oxide powder is 25, and Fe powder is reduced iron powder, iron powder Particle size ≤ 2μm. The ball-to-material ratio is 7:1, the rotation speed is 250rpm, and the ball milling time is 25min to obtain the mixed powder;

[0057] The mixed powder was first reduced with hydrogen, the reduction temperature was 300°C, and the reduction time was 120 minutes; after the reduction, the temperature was continued to rise to 750°C, and the holding time was 5 hours to obtain Cu-coated Fe powder.

[0058] 2) Cold isostatic pressing: Encapsulate Cu-coated Fe powder in an elastic plastic mold, seal it and put it into a high-pressure cylinder with a pressing force of 200 MPa and a pressing time of 200 s.

[0059] 3) Pre-sintering: Pre-sintering the blank at 850° C. for 100 min in a hydrogen atmosphere. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com