High-throughput multilayer composite nano-filtration membrane and preparation method thereof

A multi-layer composite, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low water flux, damage, and uneven surface of porous support membranes. To achieve the effect of less defects and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Get 2g of microcrystalline cellulose and place it in a container, add 20mL of sulfuric acid aqueous solution with a mass concentration of 64% dropwise into the microcrystalline cellulose, keep the temperature of the mixture at 0°C in an ice bath, and cool the mixture with a constant temperature water bath after the addition is completed. The temperature was raised to 45°C, and the reaction was stirred for 4h.

[0043]The above reacted mixture is slowly poured into ten times the volume of ultrapure water for dilution, and centrifuged and washed three times. The obtained product is dialyzed through a dialysis bag until the solution is neutral, and finally freeze-dried to obtain nanocrystalline cellulose powder.

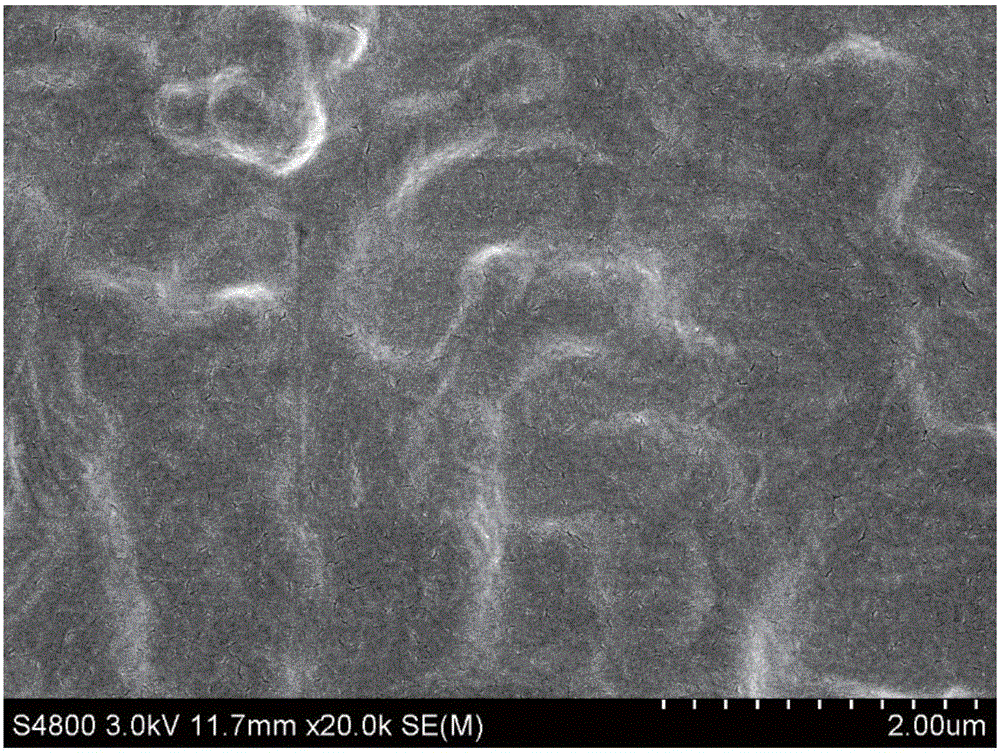

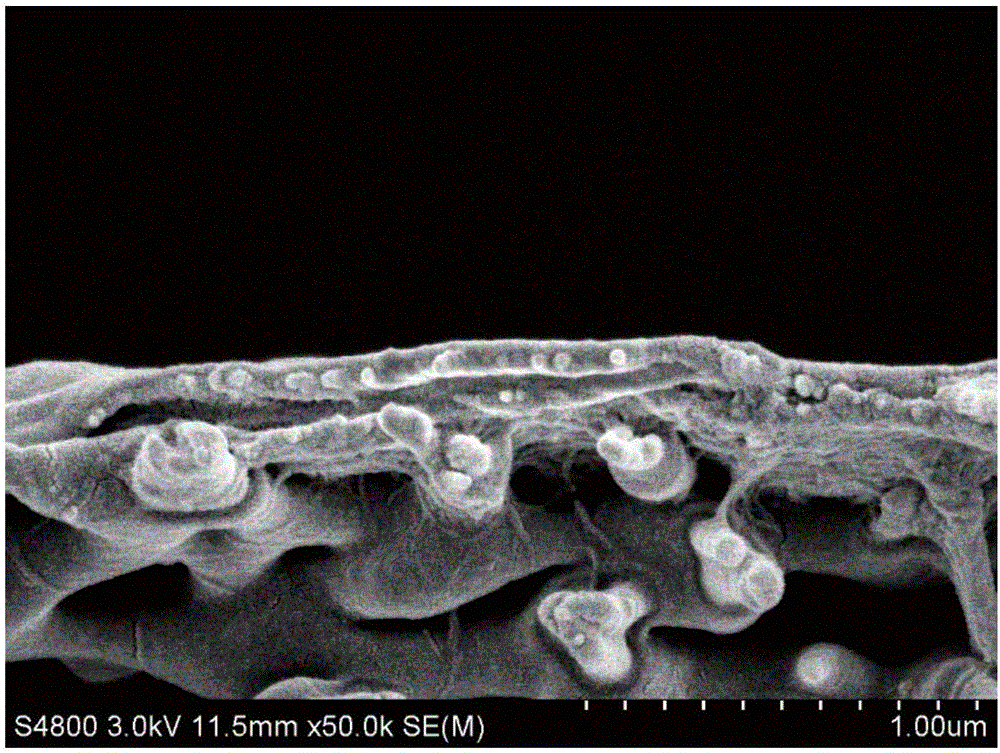

[0044] The nanoscale cellulose powder was dispersed in water and ultrasonically dispersed for 2 h to obtain a 0.08 g / L nanocrystalline cellulose suspension.

[0045] Lay the polysulfone ultrafiltration membrane on the Buchner funnel, pour 10mL of nanocrystalline ...

Embodiment 2~4

[0048] Adjust the concentration of the water phase monomer piperazine and the oil phase monomer trimesoyl chloride, and the rest of the conditions are the same as in Example 1.

Embodiment 5~8

[0052] By adjusting the amount of nanocrystalline cellulose suspension used in the suction filtration process to adjust the loading capacity of nanocrystalline cellulose on the surface of the porous membrane, the concentration of piperazine in the aqueous phase solution is 0.3g / L, and the concentration of trimesoyl chloride in the oil phase solution Be 0.3g / L, all the other conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com