Method for integrating waste sulfuric acid treatment engineering and gypsum crystal whisker production

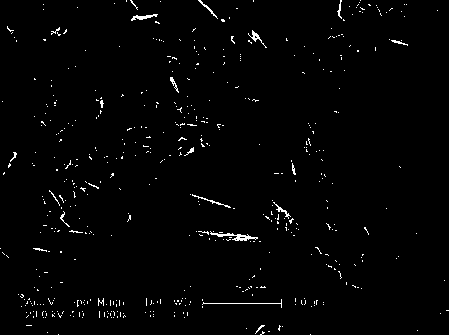

A technology for gypsum whiskers and dihydrate gypsum whiskers is applied in the field of integration of waste sulfuric acid treatment engineering and gypsum whisker production, and achieves the effects of being difficult to break, simple in method, and large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

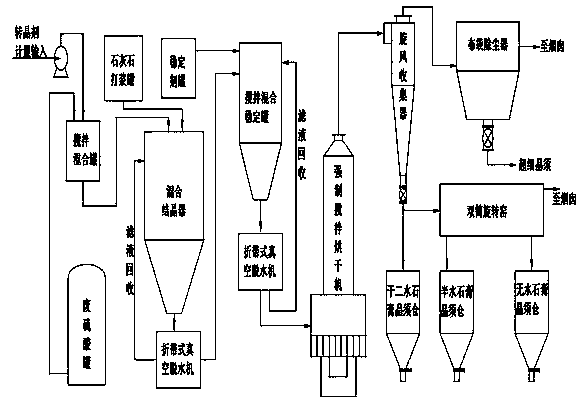

[0025] to combine figure 1 , figure 2 , image 3 , Figure 4 , a method of integrating waste sulfuric acid treatment engineering and gypsum whisker production, collecting waste sulfuric acid discharged from the factory, then filtering to remove solid impurities, diluting the filtered waste sulfuric acid to make a sulfuric acid solution, and putting the waste sulfuric acid into Reserve in the tank. The preferred waste sulfuric acid is diluted to a sulfuric acid solution with a concentration of 5-7%. Grind calcium carbonate and add water to make a calcium carbonate slurry. You can choose the first-grade Ya'an white calcium carbonate, a specialty of Sichuan, with a grade of 90-98. %, whiteness 90-95, finely ground to more than 325 mesh, the concentration of the calcium carbonate slurry is 30-50%; adding a crystal-transforming agent to the sulfuric acid solution, and the crystal-transforming agent is a solution with a concentration of 50% , the solute is one or a combination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com