Production process of soundproof cotton

A production process and technology of sound insulation cotton, which is applied in the field of production technology of sound insulation cotton, can solve the problems such as the need for improvement of sound insulation performance, insufficient light weight, and unsatisfactory strength of sound insulation cotton, and achieve long-term stability and reliability of sound insulation and sound absorption performance, long service life, Clean looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

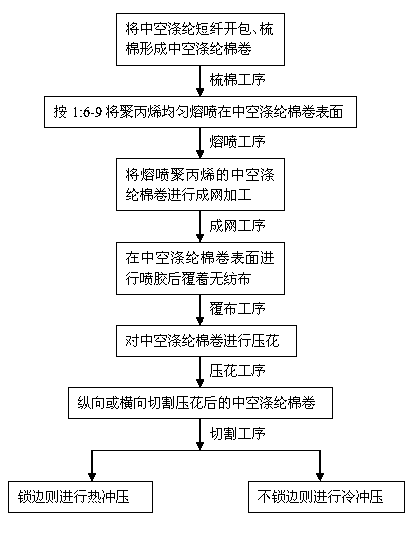

[0018] Such as figure 1 As shown, the present embodiment provides a production process of sound-insulating cotton, comprising the following steps:

[0019] a. Carding process: Unpack the hollow polyester staple fiber through the bale unpacking machine, and arrange it through the cotton feeder and carding machine to form a hollow polyester cotton lap with a width of 1.8m and a thickness of 4.5cm;

[0020] b. Melt-blown web forming process: After liquefying the solid polypropylene, the polypropylene and hollow polyester cotton rolls are evenly melt-blown on the surface of the hollow polyester cotton rolls at a ratio of 1:7, and the hollow polyester cotton rolls after melt-blown polypropylene are melt-blown using a web forming machine. Polyester cotton rolls are processed into webs;

[0021] c. Cloth covering process: liquefy the solid colloid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com