Aluminum-based boron carbide composite material and neutron absorption plate

A neutron absorbing plate and composite material technology, which is applied in the field of boron carbide aluminum matrix composite materials and neutron absorbing plates, can solve problems such as safety accidents, rupture of neutron absorbing plates, radiation, etc., so as to improve mechanical properties and prevent breakage , Improve the effect of storage safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The boron carbide aluminum-based composite material is prepared according to the liquid stirring method, and the specific preparation process is carried out according to the following steps:

[0028] 1) Ingredients: Weigh a certain quality of Al, Al-Ti master alloy and B 4 C powder; cleaning pure Al and Al-Ti master alloy; preheating B 4 C powder. When determining the quality of the raw materials here, the respective quality is calculated according to the final design goal. For example, it is hoped to prepare 100 kg of composite material, and it is hoped that the composite material contains 30 kg of B 4 C (30%), and 5 kg of Ti element (5%), 65 kg of Al element (65%), then B 4 C powder takes 30 kg; if Al-Ti-10 alloy is used, the Al-Ti-10 alloy takes 50 kg, so that Ti has 5 kg, Al has 45 kg, and the remaining pure Al raw material is 20 kg, which is 65 kg The Al element. Theoretically, it can be converted according to the above principles. In practice, considering the proble...

Embodiment 2

[0033] Example 2 is different from Example 1 in that the content of each component is changed.

[0034] For specific preparation, only step 1) Weigh a certain quality of Al, Al-Ti master alloy and B 4 The specific quality of the C powder is different, and the rest of the steps are the same as those in Example 1. The boron carbide-aluminum-based composite material in this example is prepared, and the chemical precipitation method is analyzed to obtain 33% B 4 C. It is determined by X-ray fluorescence spectrometry to obtain 3.5% Ti element and 62% Al element. In addition, a small amount (0.5% to 5%) of impurities (Al 3 BC and other impurity elements).

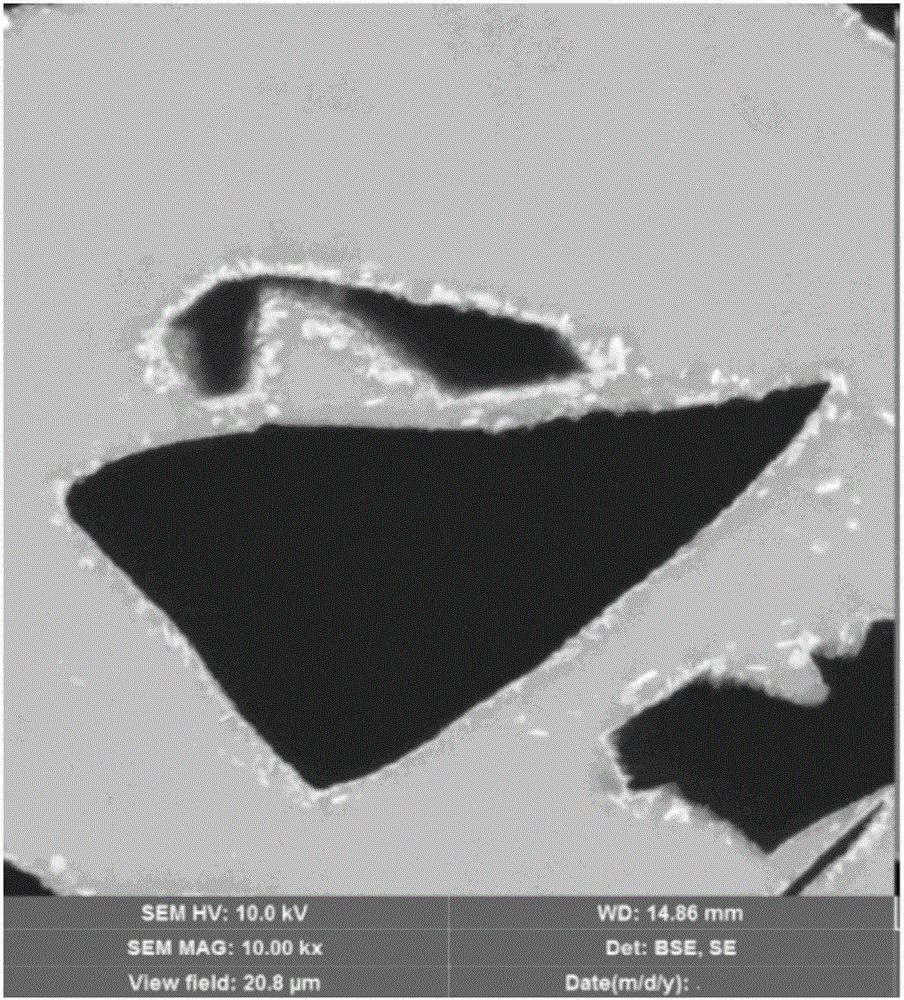

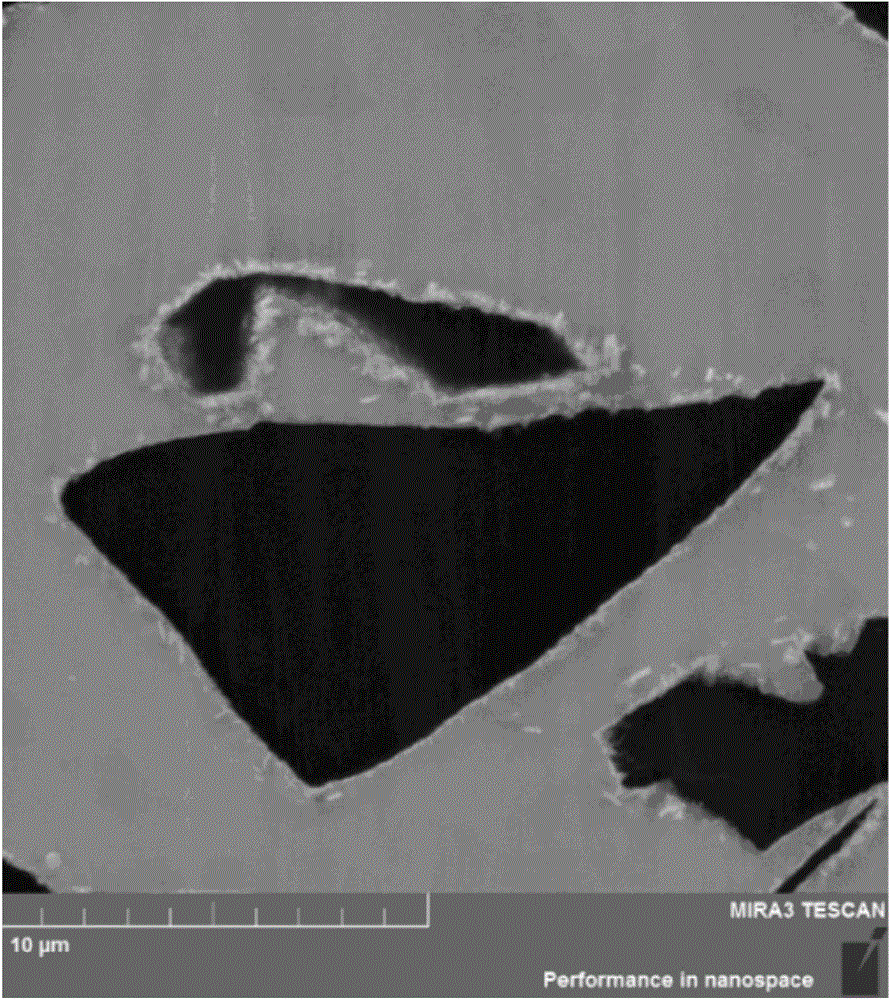

[0035] Such as figure 1 with 2 Shown are the scanning electron microscope topography and backscattering images of the boron carbide aluminum-based composite material in this embodiment, respectively. It can be found from the microstructure photo that in B 4 The surface of C particles is coated with a dense layer of Ti-B reaction produc...

Embodiment 3

[0037] The difference between Example 3 and Example 1 is: the content of each component has changed, the key change is the increase in Ti content, and a part of Ti is coated on B in the form of Ti-B compound. 4 C particle surface, the rest Ti is Al 3 The Ti form is dispersed in the aluminum matrix.

[0038] For specific preparation, only step 1) Weigh a certain quality of Al, Al-Ti master alloy and B 4 The specific quality of the C powder is different, and the rest of the steps are the same as those in Example 1. The boron carbide-aluminum-based composite material in this example was prepared, and analyzed by the chemical precipitation method to obtain 31% B 4 C. It is determined by X-ray fluorescence spectrometry to obtain 6% Ti element and 61% Al element. In addition, some trace amounts (0.5% to 5%) of impurities (Al 3 BC and other impurity elements).

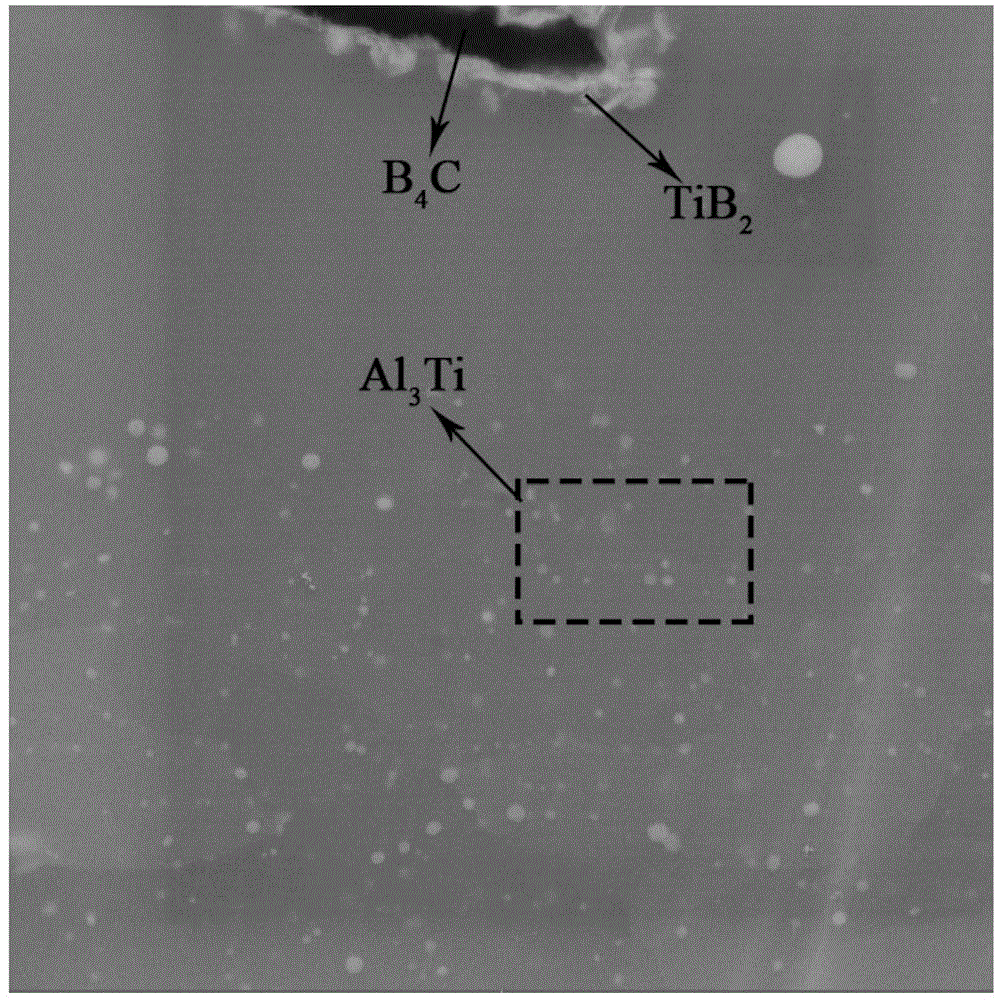

[0039] Such as image 3 Shown is the scanning electron microscope topography of the boron carbide aluminum-based composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com