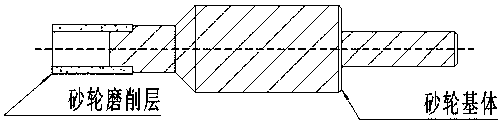

Grinding wheel applied to zirconia ceramic ferrule PC spherical surface and preparation method thereof

A technology of zirconia ceramics and grinding wheels, applied in the direction of grinding/polishing equipment, grinding devices, abrasives, etc., can solve problems such as scratches and vibration marks, low yield, easy to break, etc., to achieve the removal of lines and scratches, High processing efficiency, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0032] In the following examples, the diamond micropowder is purchased MDA type micropowder, the manufacturer is Henan Feimeng Diamond Industry Co., Ltd., and the particle size range is M2 / 4 and M0.5 / 1.5. The auxiliary abrasive boron carbide micropowder was purchased from CDA type micropowder of Luoyang Aoli Fine Chemical Co., Ltd. The technical parameters are required to meet the following table.

[0033]

[0034] In the following examples, the resin binder is a thermosetting polyimide resin powder, which is a commercially available product with a particle size range of 40-60 μm. One of the fillers, polytetrafluoroethylene (PTFE), is a common commercially available product, requiring a moisture content of <0.03%, and an average particle size of <5 μm; the second fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com