Method for preparing lithium-ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, battery electrodes, electrode manufacturing, etc., can solve the problem of easy detachment of porous membranes, and achieve the effect of preventing agglomeration or sedimentation, improving dispersibility, and not being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

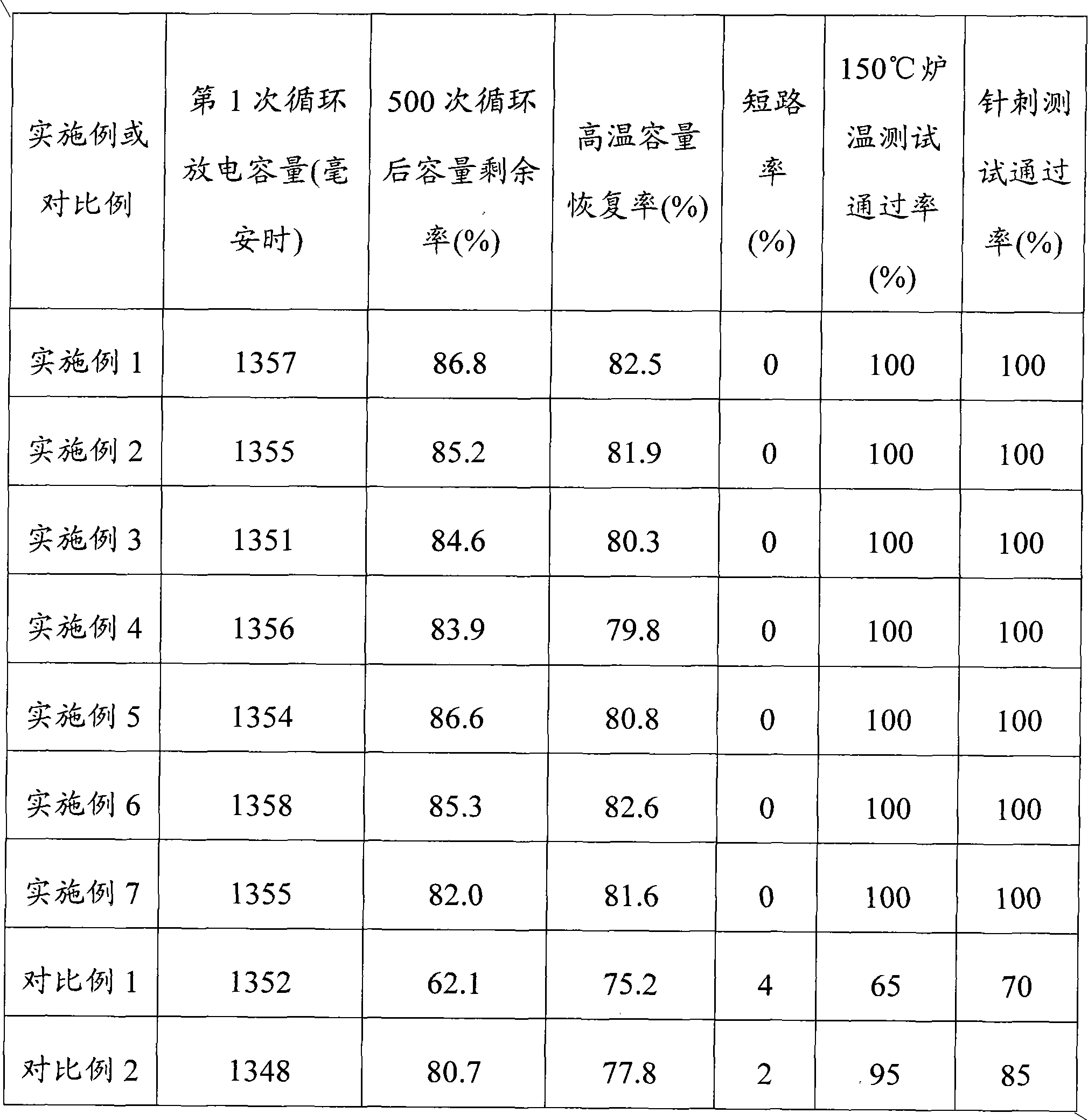

Examples

preparation example Construction

[0027] Various methods known in the art can be used for the preparation of the positive electrode sheet and the negative electrode sheet.

[0028] According to the lithium ion secondary battery provided by the present invention, the electrolytic solution is a non-aqueous electrolytic solution. The non-aqueous electrolytic solution is a solution formed of an electrolyte lithium salt in a non-aqueous solvent, and conventional non-aqueous electrolytic solutions known to those skilled in the art can be used. For example, the electrolyte lithium salt can be selected from lithium hexafluorophosphate (LiPF6), lithium perchlorate (LiClO4), lithium tetrafluoroborate (LiBF4), lithium hexafluoroarsenate (LiAsF6), lithium hexafluorosilicate (LiSiF6), tetraphenylboronic acid Lithium (LiB(C6H5)4), lithium chloride (LiCl), lithium bromide (LiBr), lithium chloroaluminate (LiAlCl4) and lithium fluorocarbonate (LiC(SO2CF3)3), LiCH3SO3, LiN(SO2CF3)2 one or more of. Non-aqueous solvent can be s...

Embodiment 1

[0032] This example is used to illustrate the preparation of the lithium ion secondary battery provided by the present invention.

[0033] 1. Preparation of positive electrode

[0034] 60 grams of polyvinylidene fluoride (PVDF) was dissolved in 770 grams of N-methyl-2-pyrrolidone (NMP) solvent to prepare a binder solution, and then 2000 grams of positive electrode active material lithium cobaltate (LiCoO2) and 40 Add 1 gram of acetylene black powder into the above solution, then add 200 grams of N-methyl-2-pyrrolidone (NMP), fully stir and mix to make positive electrode slurry; Both sides of the aluminum foil were heated and dried under vacuum at 125°C for 2 hours, rolled, and cut into pieces to obtain a positive electrode of 750 mm (length) × 55.5 mm (width) × 83 microns (thickness). Each positive electrode contained 10 grams of positive active material LiCoO2.

[0035] 2. Preparation of negative electrode

[0036] 990 grams of graphite P15B-CH (Nippon Carbon NIPPON CARBON...

Embodiment 2

[0044] This example is used to illustrate the preparation of the lithium ion secondary battery provided by the present invention.

[0045] Lithium-ion secondary batteries were prepared according to the method of Example 1, except that the additive mixture used to prepare the porous membrane slurry was prepared using 7 grams of 20% ethylamine solution, and the pH value of the slurry was adjusted to 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com