Environment-friendly deinking residue recovery and treatment production method

A technology of recycling treatment and production method, which is applied in paper recycling, fiber raw material processing, recycling technology, etc., can solve the problems of low recovery efficiency of deinking slag, high processing cost, and non-environmental protection, so as to save environmental protection management costs and improve environmental protection. Paper strength and the effect of saving paper production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of environment-friendly deinking slag recovery treatment production method, comprises the following steps:

[0052] Deinking residue collection:

[0053] The deinking slag produced in the deinking pulp line flotation tank and defoaming tank equipment is sent to the deinking slag collection tank through water flow gravity or pumped; the deinking slag collection tank is controlled by liquid level and sent to the next process for deinking The flow of slag is automatically adjusted according to the liquid level. Keep the liquid level of the collection tank stable and effectively prevent leakage caused by excessive liquid level.

[0054] In the present embodiment, the volume of the deinking slag collection tank is 25m 3 , the collected deinking slag has a flow rate of 2500-4000L / min and a concentration of 1-2%. Select a suitable centrifugal pulp pump to transport the deinking slag to the chemical reactor and mix it with the flocculant.

[0055] Flocculation pretrea...

Embodiment 2

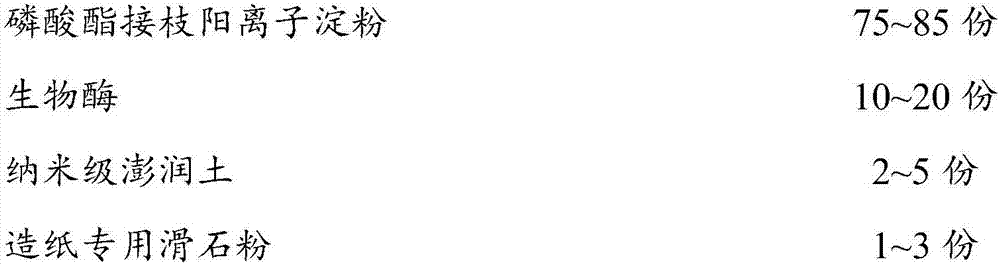

[0096] The difference between the environmentally friendly deinking slag recovery and processing production method disclosed in this embodiment and the first embodiment is that the composition of phosphate grafted cationic starch in the deinking sludge backfill agent A is 75 parts;

Embodiment 3

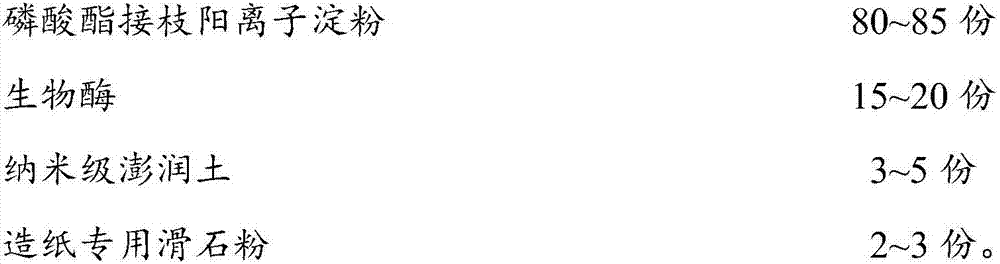

[0098] The difference between the environmentally friendly deinking slag recovery and processing production method disclosed in this embodiment and the first embodiment is that the composition of phosphate ester grafted cationic starch in the deinking sludge backfill agent A is 85 parts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com