Anti-pricking and anti-stabbing type electric car cover tyre and processing method thereof

A puncture-resistant type and processing method technology, which is applied to tires, vehicle parts, tire parts, etc., can solve the problems of loss, danger, leak-trapping glue corroding the paint surface of the wheel hub, etc., to prevent corrosion, and the device is convenient and convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

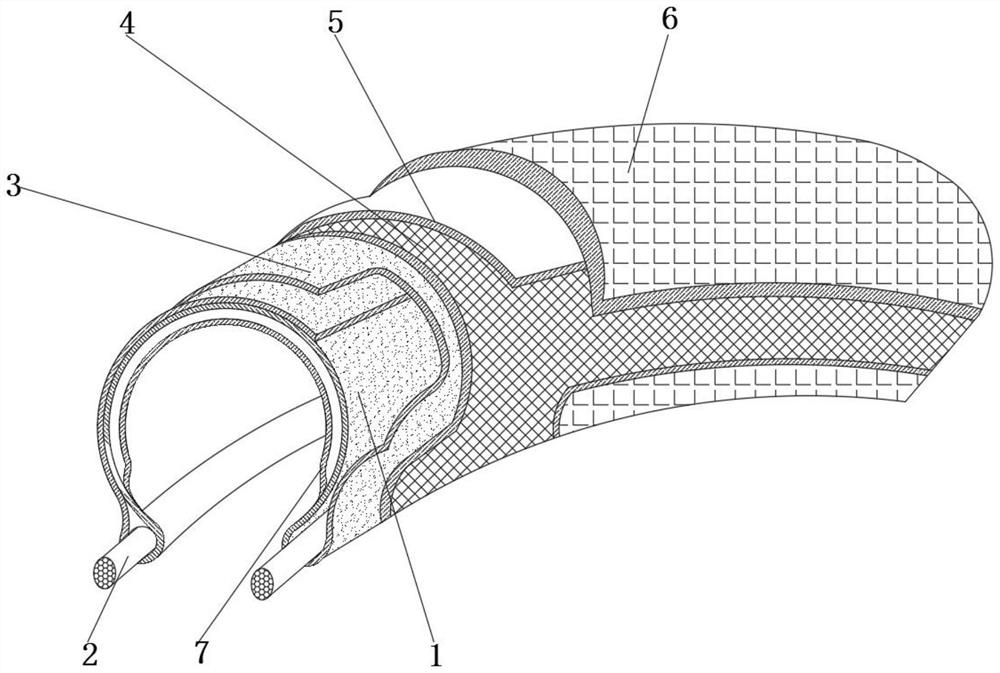

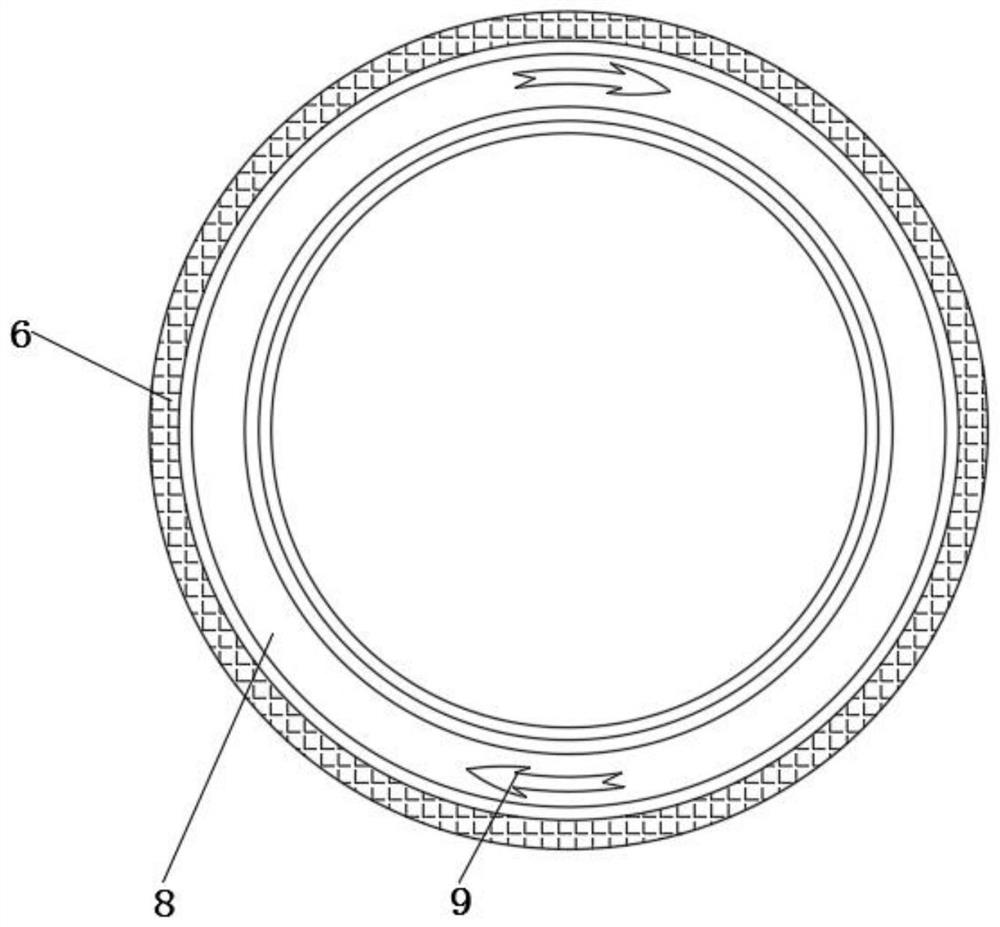

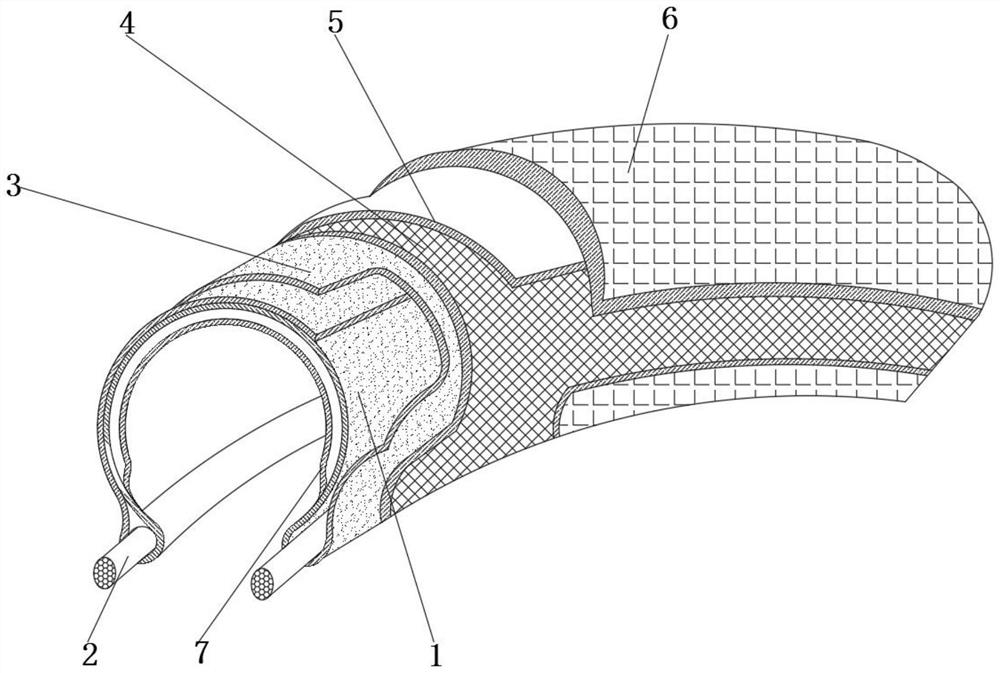

[0027] see Figure 1-2 , the present invention provides a technical solution: a puncture-resistant and stab-resistant tram tire, comprising an inner liner 1, a bead wire 2, a carcass layer 3, a ply 4, a protective layer 5, a tread rubber layer 6, injection Rubber 7, side rubber layer 8 and guide arrow 9, bead wire 2 is arranged under the inner liner 1, and a carcass layer 3 is arranged above the inner liner 1, and a carcass layer is arranged above the carcass layer 3 4, and a protective layer 5 is provided above the ply 4, a tread rubber layer 6 is arranged on the protective layer 5, and a rubber injection 7 is installed inside the inner liner layer 1, and a side rubber layer is provided on the side of the inner liner layer 1 layer 8, and guide arrows 9 are arranged on the side adhesive layer 8.

[0028] A method for processing an anti-puncture and anti-stab electric car tire, comprising the following steps in sequence:

[0029] (A) Production steps of injection foaming: add...

Embodiment 2

[0038] see Figure 1-2 , the present invention provides a technical solution: a puncture-resistant and stab-resistant tram tire, comprising an inner liner 1, a bead wire 2, a carcass layer 3, a ply 4, a protective layer 5, a tread rubber layer 6, injection Rubber 7, side rubber layer 8 and guide arrow 9, bead wire 2 is arranged under the inner liner 1, and a carcass layer 3 is arranged above the inner liner 1, and a carcass layer is arranged above the carcass layer 3 4, and a protective layer 5 is provided above the ply 4, a tread rubber layer 6 is arranged on the protective layer 5, and a rubber injection 7 is installed inside the inner liner layer 1, and a side rubber layer is provided on the side of the inner liner layer 1 layer 8, and guide arrows 9 are arranged on the side adhesive layer 8.

[0039] A method for processing an anti-puncture and anti-stab electric car tire, comprising the following steps in sequence:

[0040] (A) Production steps of injection foaming: add t...

Embodiment 3

[0049] see Figure 1-2 , the present invention provides a technical solution: a puncture-resistant and stab-resistant tram tire, comprising an inner liner 1, a bead wire 2, a carcass layer 3, a ply 4, a protective layer 5, a tread rubber layer 6, injection Rubber 7, side rubber layer 8 and guide arrow 9, bead wire 2 is arranged under the inner liner 1, and a carcass layer 3 is arranged above the inner liner 1, and a carcass layer is arranged above the carcass layer 3 4, and a protective layer 5 is provided above the ply 4, a tread rubber layer 6 is arranged on the protective layer 5, and a rubber injection 7 is installed inside the inner liner layer 1, and a side rubber layer is provided on the side of the inner liner layer 1 layer 8, and guide arrows 9 are arranged on the side adhesive layer 8.

[0050] A method for processing an anti-puncture and anti-stab electric car tire, comprising the following steps in sequence:

[0051] (A) Production steps of injection foaming: add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com