Microencapsulated tungsten disulfide dry-film lubricant

A dry film lubricant, tungsten disulfide technology, applied in microcapsule preparations, lubricating compositions, microsphere preparation, etc., to achieve the effect of improving antifriction and antiwear ability, excellent dispersion stability and friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

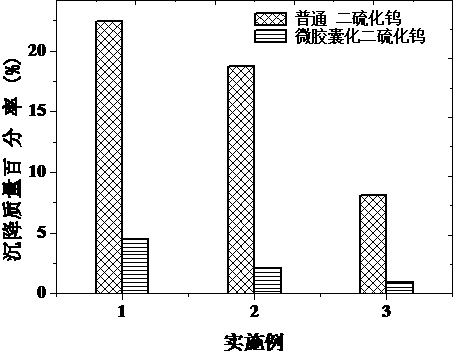

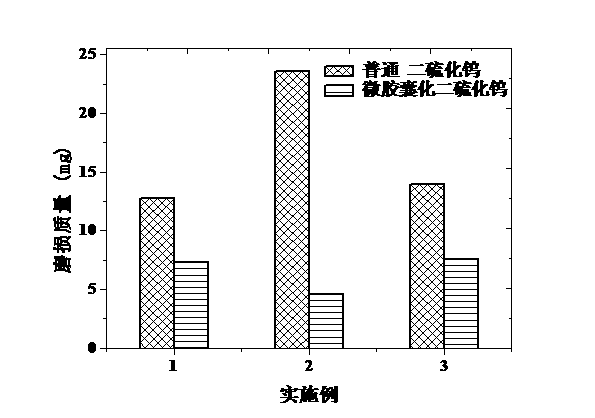

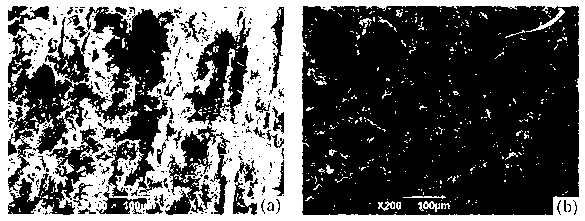

Examples

Embodiment 1

[0028] 1. Microencapsulation treatment of tungsten disulfide

[0029] Select tungsten disulfide particles with an average particle size of 50nm; mix ethyl cellulose and glycerin, stir and heat up to 80°C to completely dissolve ethyl cellulose in glycerin; then add tungsten disulfide particles and thio Semicarbazide, ultrasonically dispersed for 20 minutes, so that the tungsten disulfide particles are evenly dispersed in the solution. As the temperature naturally decreases, the solubility of ethyl cellulose decreases and the tungsten disulfide particles are used as nuclei to condense and precipitate, initially forming tungsten disulfide microcapsules; After cooling to room temperature, the microcapsules were solidified, and finally the tungsten disulfide microcapsules were recovered by filtration, washed with glycerin, and dried naturally at room temperature for later use.

[0030] 2. Preparation of microencapsulated tungsten disulfide dry film lubricant

[0031] Dry film lubr...

Embodiment 2

[0033] 1. Microencapsulation treatment of tungsten disulfide

[0034]Select tungsten disulfide particles with an average particle size of 120nm; mix carboxymethyl cellulose and cyclohexane, stir and heat up to 76°C to completely dissolve carboxymethyl cellulose in cyclohexane; add two Tungsten sulfide particles and thiosemicarbazide were dispersed by ultrasonic waves for 20 minutes, so that tungsten disulfide particles were evenly dispersed in the solution. As the temperature naturally decreased, the solubility of carboxymethyl cellulose decreased and condensed and precipitated with tungsten disulfide particles as nuclei. Tungsten disulfide microcapsules are formed; after cooling to room temperature, the microcapsules solidify, and finally the tungsten disulfide microcapsules are recovered by filtration, washed with cyclohexane, and dried naturally at room temperature for later use.

[0035] 2. Preparation of microencapsulated tungsten disulfide dry film lubricant

[0036] Dr...

Embodiment 3

[0038] 1. Microencapsulation treatment of tungsten disulfide

[0039] Select tungsten disulfide particles with an average particle size of 200nm; mix cellulose acetate phthalate and ethanol, stir and heat up to 80°C to completely dissolve cellulose acetate phthalate in ethanol; add two Tungsten sulfide particles and thiosemicarbazide were dispersed by ultrasonic waves for 20 minutes, so that tungsten disulfide particles were evenly dispersed in the solution. As the temperature naturally decreased, the solubility of cellulose acetate phthalate decreased and condensed and precipitated with tungsten disulfide particles as nuclei , initially formed tungsten disulfide microcapsules; after cooling to room temperature, the microcapsules were solidified, and finally the tungsten disulfide microcapsules were recovered by filtration, washed with ethanol, and dried naturally at room temperature for later use.

[0040] 2. Preparation of microencapsulated tungsten disulfide dry film lubric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com