Production mixing mechanism for industrial intelligent manufacturing

An intelligent manufacturing and industrial technology, applied in the direction of mixers, mixing methods, mixer accessories, etc., can solve problems such as unfavorable rapid production, difficult liquid mixing and dissolution, etc., to avoid damage to parts, avoid waste of raw materials, and reduce resistance.

Active Publication Date: 2022-06-21

肯拓(天津)工业自动化技术有限公司 +1

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the process of industrial production, it is necessary to mix and stir the solid powder and liquid. During the process of adding liquid and stirring, the solid powder on the inner wall of the mixing drum is easy to stick to the inner wall of the mixing drum, but the stirring in the prior art Most of the rods are not in contact with the inner wall of the mixing drum. During the mixing process, the solid powder sticking to the inner wall of the mixing drum is difficult to mix and dissolve with the liquid in time, which is not conducive to rapid production. In view of this, we propose an industrial intelligent manufacturing. production mixing mechanism

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

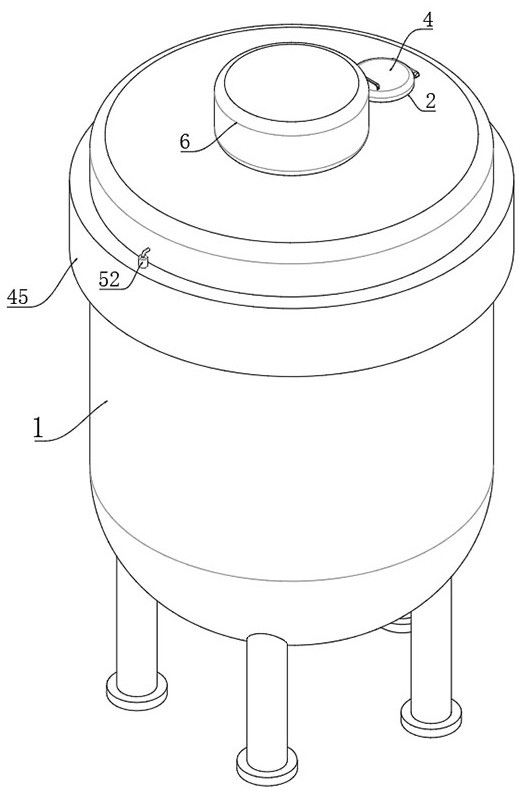

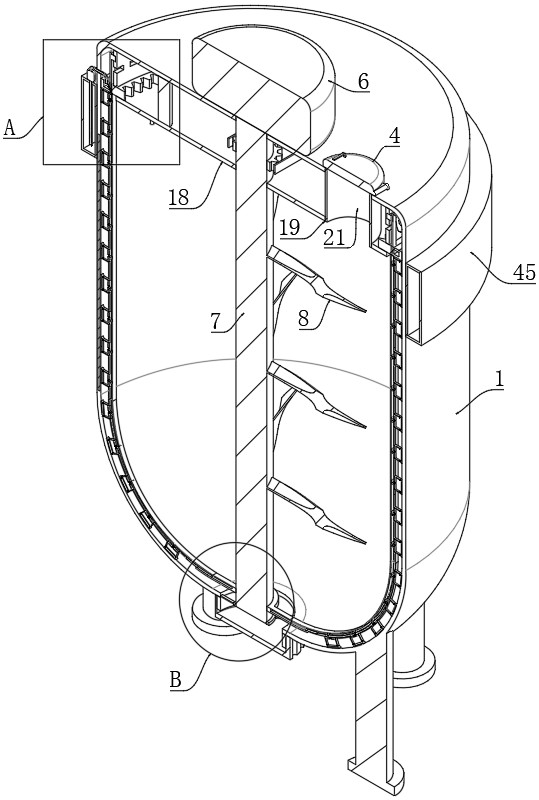

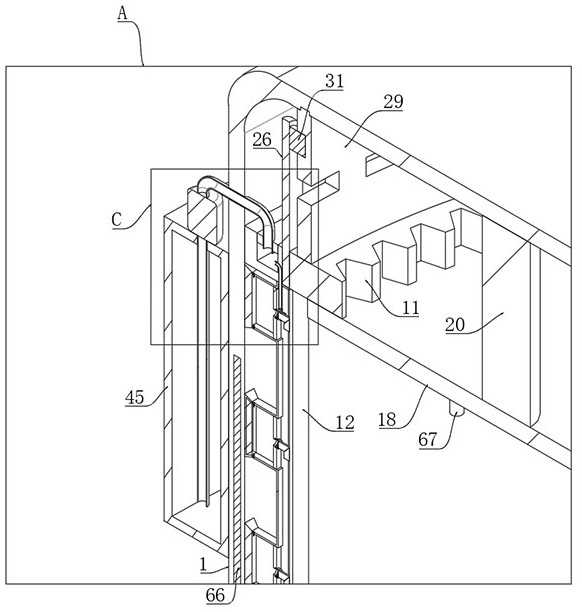

The invention relates to the technical field of production mixing, in particular to an industrial intelligent manufacturing production mixing mechanism which comprises a stirring barrel, a feeding port is formed in the top surface of the stirring barrel, a discharging pipe is fixedly communicated with the bottom surface of the stirring barrel, a sealing door is hinged to the edge of the feeding port, a sealing cover is in threaded connection with the discharging pipe, and the sealing cover is in threaded connection with the stirring barrel. A motor is fixed on the top surface of the stirring barrel, the tail end of an output shaft of the motor penetrates through the top surface of the stirring barrel, extends into the stirring barrel and then is fixedly provided with a stirring rod, and a plurality of stirring blades are fixed on the stirring rod; according to the multi-point scraping device, the resistance of a mixture to the multi-point scraping mechanism is reduced by setting up and down scraping of multiple point positions and reducing the scraping distance, and the stirring rod is linked with the transmission mechanism to drive the inner gear to rotate, so that the rotation directions of the multi-point scraping mechanism and the mixture are the same, and in the movement process of the multi-point scraping mechanism, the stirring effect is improved. And the resistance of the mixture to the multi-point scraping mechanism is further reduced.

Description

technical field [0001] The invention relates to the field of production mixing, in particular to a production mixing mechanism for industrial intelligent manufacturing. Background technique [0002] A mixer is a mechanical device that uses mechanical force and gravity to evenly mix two or more materials. In the process of mixing, it can also increase the contact surface area of materials to promote chemical reactions; it can also accelerate physical changes. [0003] Some invention patents related to production mixing are disclosed in the prior art. The Chinese patent application number is 201120243442.0, which discloses a solid-liquid mixing equipment, including material crushing equipment and pulping mixing tank. The material crushing equipment is installed in the feeding funnel ; The material crushing equipment includes a motor, a small pulley, a transmission belt, a large pulley, a crushing stirring shaft and an auger. [0004] In the process of industrial production...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F35/12B01F35/53B01F35/71B01F23/53

Inventor 陈玉峰王雨舟葛云涛叶晓明李明轩

Owner 肯拓(天津)工业自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com