Drying equipment for disinfecting medical apparatus and instruments

A technology for drying equipment and medical equipment, applied in the field of medical drying, can solve the problems of difficulty in ensuring the air quality inside the air inlet duct, speeding up the work efficiency of medical staff, shortening the sterilization distance, etc., so as to reduce drying time and labor. the effect of increasing the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

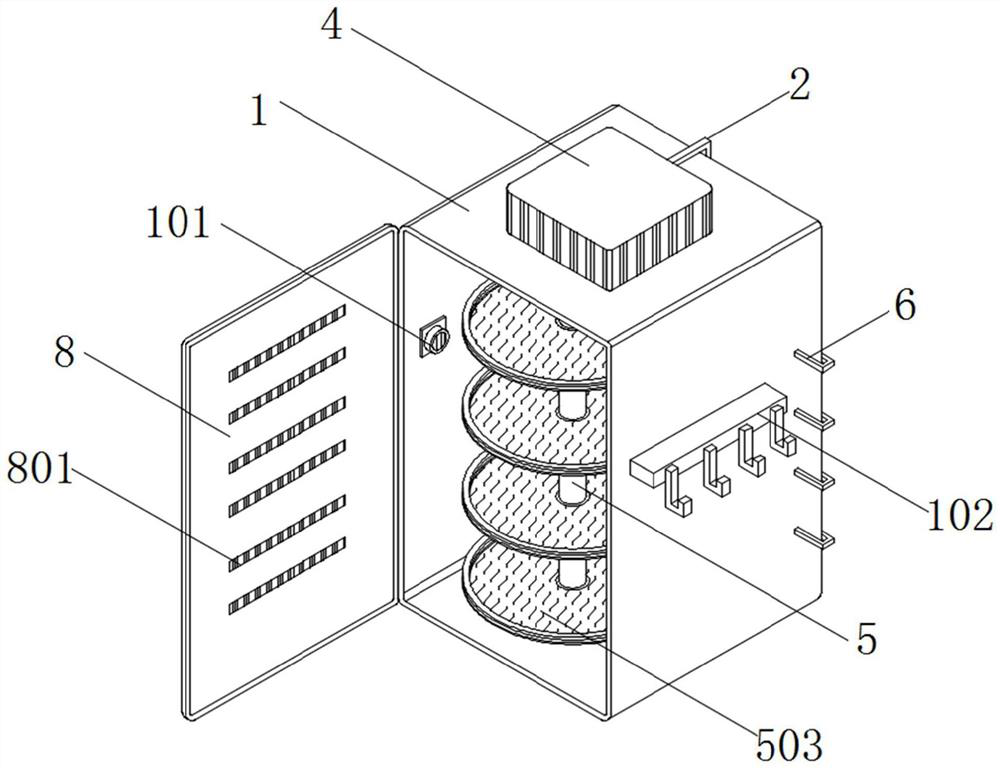

[0056] see figure 1 , figure 2 , image 3 with Figure 4 , an embodiment provided by the present invention: a drying equipment for disinfection of medical instruments, comprising a drying cabinet body 1 and a sterile air inlet pipe 2, the top of the drying cabinet body 1 is equipped with a drying adjustment box 4, an L-shaped sterile air inlet pipe 2 is installed through the back of the drying adjustment box 4;

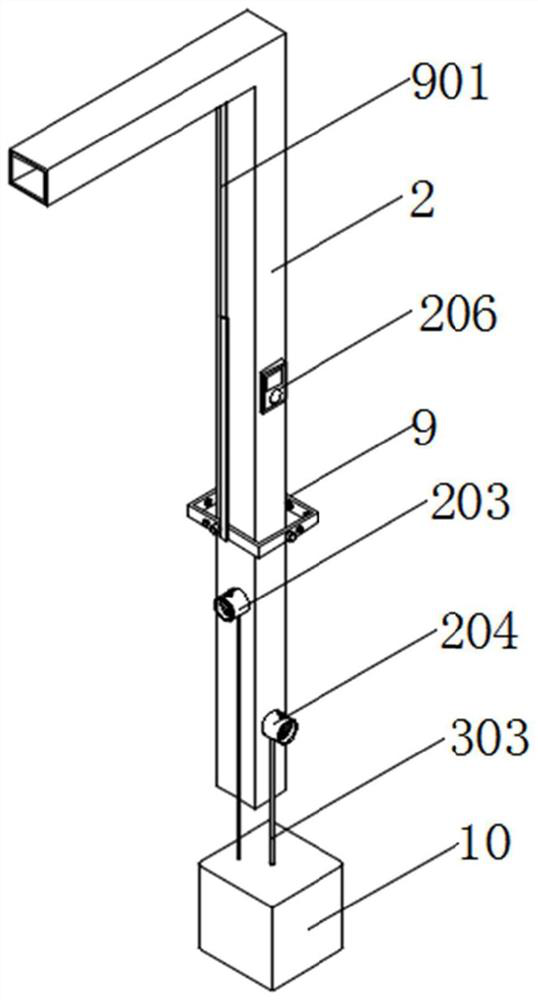

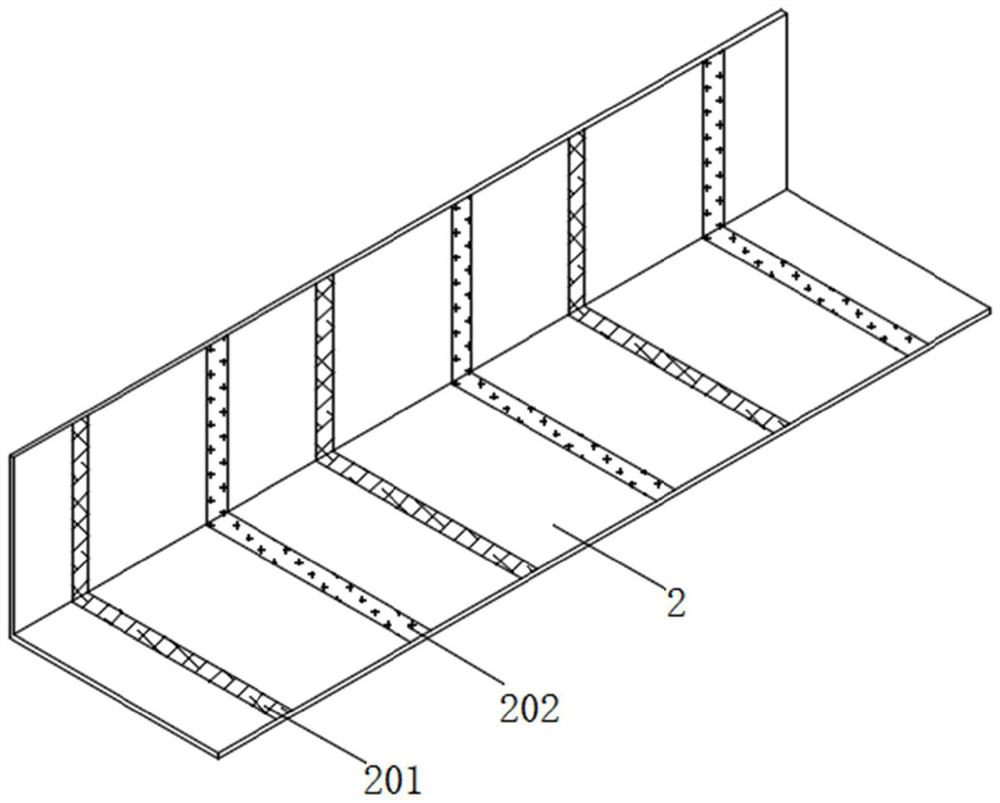

[0057] The inner wall of the sterile air inlet pipe 2 is equidistantly arranged with ultraviolet lamp circles 201 and heating mesh circles 202, and the ultraviolet lamp circles 201 and heating mesh circles 202 are arranged at intervals, and the tail end of the sterile air inlet pipe 2 is a closed structure, sterile The surface of the air inlet pipe 2 is equipped with No. 1 air inlet pipe 203 and No. 2 air inlet pipe 204 arranged up and down, and No. 1 air inlet pipe 203 and No. 2 air inlet pipe 204 are respectively in two mutually perpendicular planes. An electro...

Embodiment 2

[0067] see figure 1 , Figure 5 with Image 6 , an embodiment provided by the present invention: a drying equipment for medical device disinfection, comprising a drying cabinet body 1 and a drying adjustment box 4, a heating frame 402 is installed on the inner wall of the drying adjustment box 4, and the drying The bottom wall of the dry adjustment box 4 is installed with a regulating pipe 401, and the tail end of the regulating pipe 401 extends to the inside of the drying cabinet body 1. The inner wall of the regulating pipe 401 is equipped with a one-way valve 404, and the inner wall of the regulating pipe 401 A support frame 406 is installed, the bottom of the support frame 406 is connected with a miniature electric telescopic rod 405, the tail end of the miniature electric telescopic rod 405 is connected with a tapered air outlet pipe 403 through the support frame 406, and the inner support frame 406 of the tapered air outlet pipe 403 The size is smaller than the size of...

Embodiment 3

[0075] see figure 1 , Figure 7 with Figure 8 , an embodiment provided by the present invention: a drying equipment for medical device disinfection, comprising a drying cabinet body 1 and a support rod 5, the top wall of the drying cabinet body 1 is equipped with a support rod 5, and The length of the support rod 5 is less than the internal height of the drying cabinet cabinet 1, the surface of the support rod 5 is equipped with a drying rack 501 through the bearing sleeve, and the inside of the drying rack 501 is provided with a storage tank 502, and the inside of the storage tank 502 is embedded A semicircular net plate 503 is installed together, and a protruding strip 504 is installed on the surface of the net plate 503 , and the cross-sectional dimension of the protruding strip 504 is larger than that of the receiving groove 502 .

[0076] Specifically, after drying, in order to prevent medical personnel from manually picking up the dried medical equipment, the accepted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com