Connecting process of far infrared nano electrothermal film electrode blind holes and wire

A far-infrared nano-wire connection technology, which is applied to ohmic resistance electrodes and ohmic resistance heating parts, can solve the problems of easy loosening and falling off of the connection between the wire and the electric heating film, so as to improve stability, increase service life and reduce looseness The effect of the probability of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

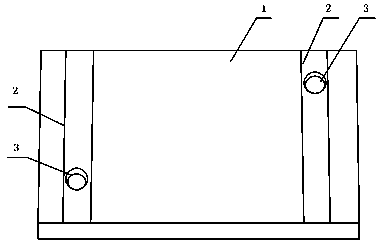

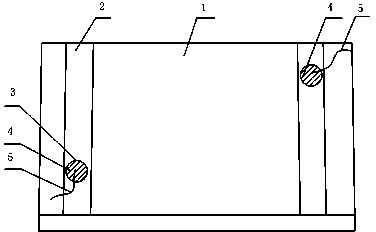

[0025] At both ends of the base material 1 with glass-ceramic as the far-infrared nano-electric heating film, use a φ6 hole opener to drill two blind holes 3 with a depth of 2mm, and use a 250-mesh screen on the position of the blind hole 3 of the base material 1. Print the electrode silver paste strips 2 at both ends, set the power to be below 1000w, and the width of the electrode silver paste strip 2 is 7mm, and then embed a φ0.93 silver wire 5 in the blind hole 3, and then use a temperature of 90°C to low temperature The substrate 1 and the electrode silver paste belt 2 are heated for 6 minutes. The heated substrate 1 is taken out, and the high-temperature silver paste 4 with a silver content of 75% is injected into the blind hole 3 . Then put it into a low-temperature oven at 90° C. for drying for 15 minutes. After taking it out, put it into a high-temperature oven at 600°C for the first sintering, and the sintering time is 6 minutes. After high-temperature sintering, wh...

Embodiment 2

[0027] At both ends of the substrate 1 with ceramics as the far-infrared nano-electric heating film, use a φ6 hole opener to drill two blind holes 3, the depth of which is 2mm, and use 300 mesh screen printing on the position of the blind holes 3 of the substrate 1. Electrode silver paste strips 2 at both ends, the set power is above 2000w, the width of the electrode silver paste strip 2 is 12mm, and φ0.93 silver wire 5 is embedded in the blind hole 3, and then heated at a low temperature of 120°C Substrate 1 and electrode silver paste belt 2, the heating time is 7 minutes. The heated substrate 1 is taken out, and the high-temperature silver paste 4 with a silver content of 75% is injected into the blind hole 3 . Then put it into a low-temperature oven at 120° C. for drying, and the drying time is 15 minutes. After taking it out, put it into a high-temperature oven at 620°C for the first sintering, and the sintering time is 6 minutes. After high-temperature sintering, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com