Mixing and laying device of asphalt mixture for road engineering

A technology for asphalt mixture and road engineering, which is applied in the field of mixing and paving devices for asphalt mixture for road engineering, which can solve the problems of unfinished screed, pits not paved, time-consuming and labor-intensive, etc., and achieves the goal of improving paving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

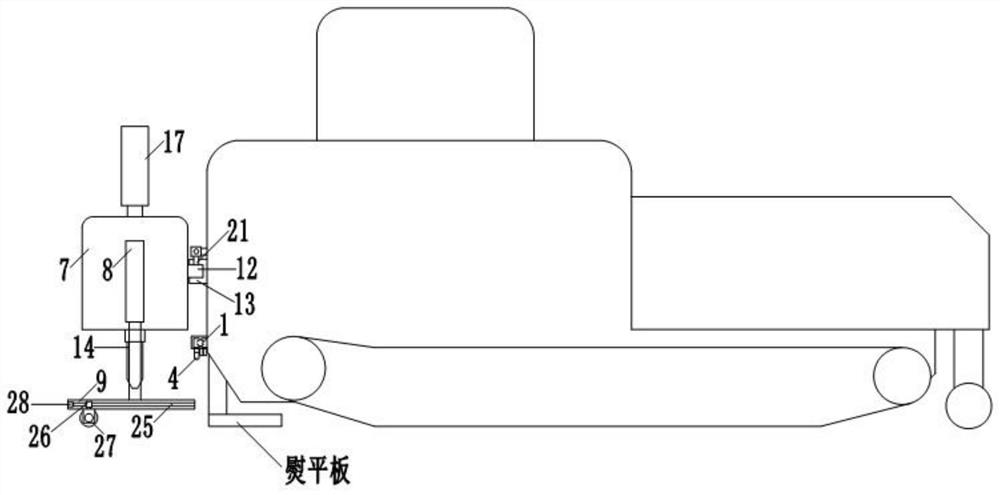

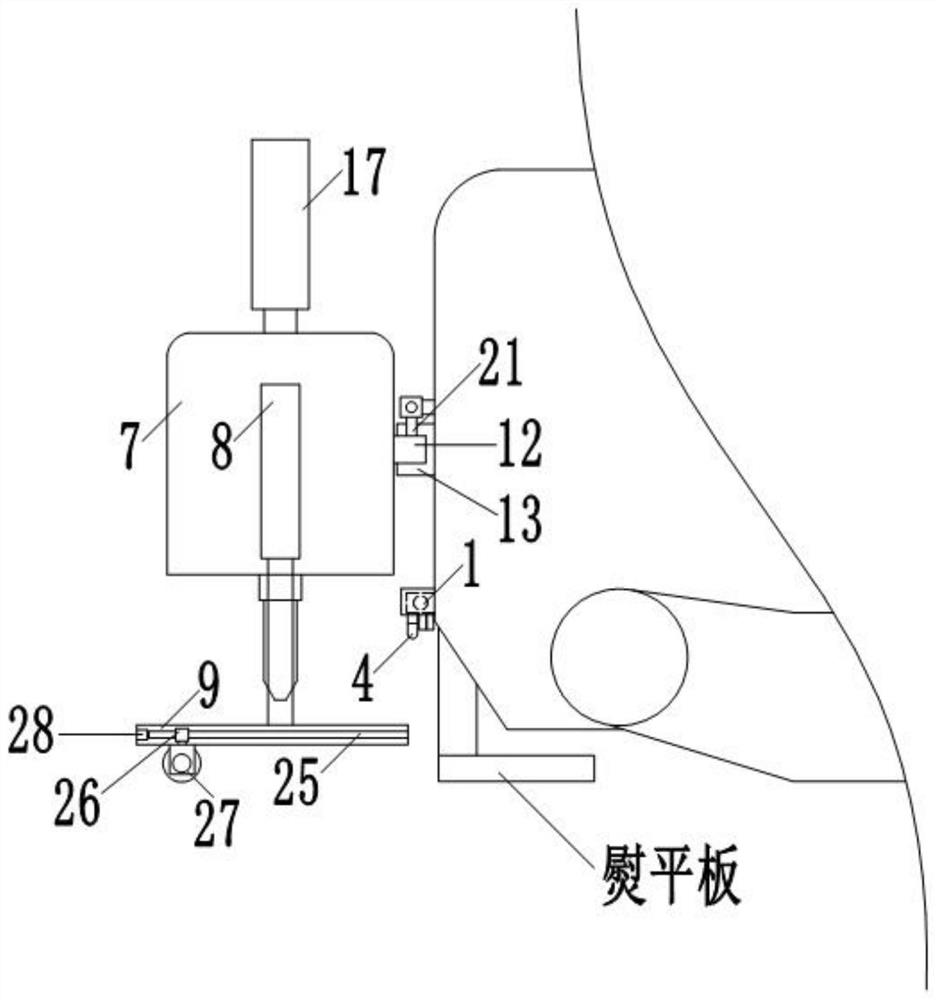

[0042] Such as figure 1As shown, the embodiment of the present invention provides a mixing and paving device for asphalt mixture for road engineering, including a measuring mechanism, a feeding mechanism, a paving mechanism and a controller 11; On the paver, it is located behind the screed of the paver; the nut 2 is screwed to the screw 1; the output shaft of the first motor 3 is connected to one end of the screw 1; the laser rangefinder 4 is fixed on the side of the nut 2 On the wall, the side wall of the nut 2 is also fixed with a camera 5 and a locator 6; the feeding mechanism, including the material storage box 7, is slidably connected with the paver through a sliding assembly; the lateral movement mechanism is fixed on the side wall of the paver Drive the storage box 7 to move laterally; the discharge assembly is connected to the outlet of the storage box 7; ; The paving mechanism includes a lifter 8, its fixed end is fixed on the side wall of the storage box 7, and its ...

Embodiment 2

[0046] This embodiment is based on Embodiment 1, the sliding assembly includes a first sliding block 12, the first sliding block 12 is fixed on the side wall of the storage box 7, and the first sliding block 12 is slidably connected with the first chute 13 , the first chute 13 is located above the screw 1 and is fixed laterally on the paver.

Embodiment 3

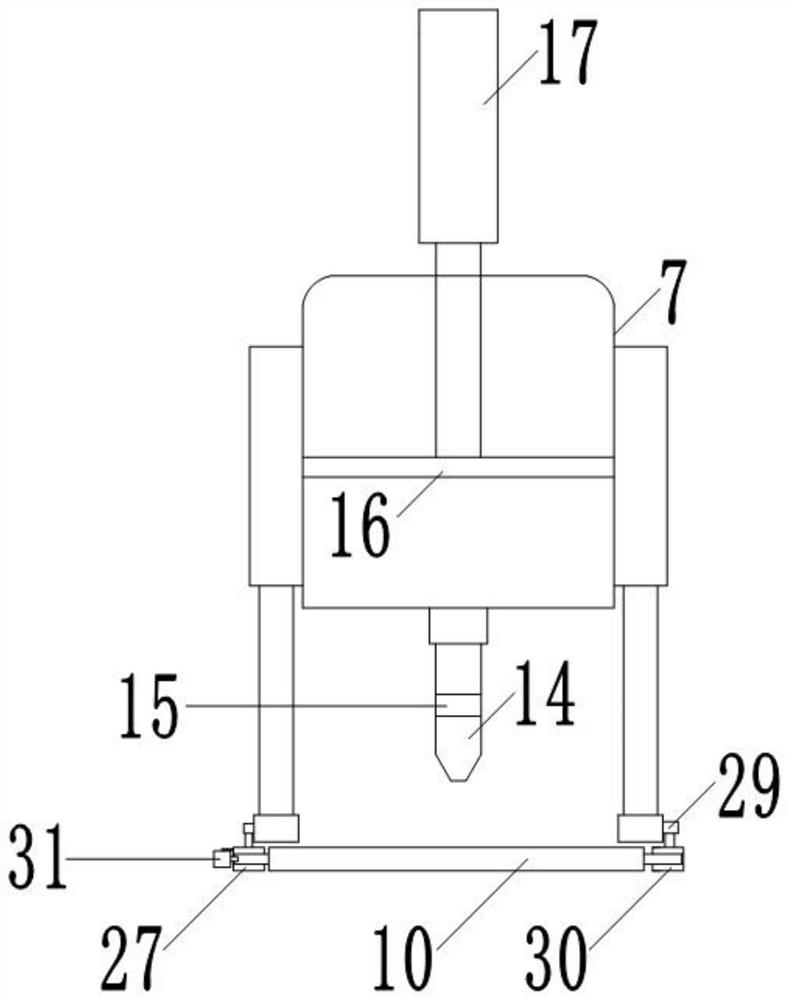

[0048] The present embodiment is based on Embodiment 1, and the discharge assembly includes a discharge pipe 14, placed vertically, its upper end is threadedly connected with the discharge port of the material storage box 7, and its lower end is facing the asphalt ground; the electromagnetic valve 15 is connected with the The controller 11 is connected inside the discharge pipe 14 for controlling the asphalt discharge.

[0049] The present invention utilizes a solenoid valve 15 to control the discharge of asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com