Polylactic acid porous microspheres as well as preparation method and application thereof

A technology of polylactic acid microspheres and porous microspheres, which is applied in the fields of pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of inconvenience to consumers, short action time, etc., to improve the recovery rate, facilitate volatilization, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of polylactic acid porous microspheres, comprising the following steps:

[0043] Step S10, dissolving polylactic acid in methylene chloride to form a polylactic acid solution, and then adding polyethylene glycol as a porogen and mixing evenly to obtain an oil phase solution;

[0044] Specifically, in order to make polylactic acid dissolve better, polylactic acid is dissolved in methylene chloride through a vortex mixer, and the concentration of polylactic acid in methylene chloride is 10% to 30%; the amount of polyethylene glycol and The dosage ratio of the polylactic acid is 0.1:1-3:1, and the molecular weight of the polylactic acid is 3W-10W.

[0045] Step S20, pour the polyvinyl alcohol raw material into a beaker, add deionized water, and stir at 97°C using a magnetic stirring water bath until the polyvinyl alcohol is completely dissolved, and the solution is colorless and transparent, and the concentration is prepared to be 4.0%~ 6.0% polyvinyl...

Embodiment 1

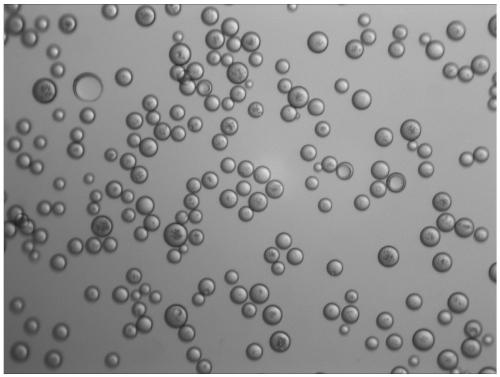

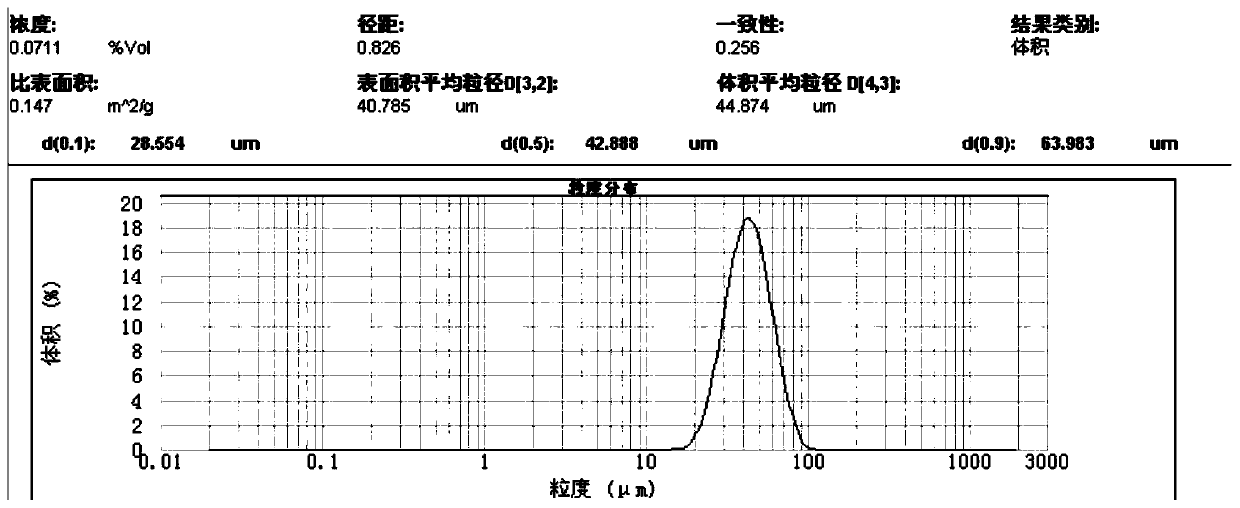

[0069] Dissolve racemic polylactic acid (PDLLA) with a molecular weight of 50,000 in dichloromethane to prepare a polylactic acid solution with a concentration of 15 wt%, and then add polyethylene glycol (PEG- 400) as a porogen, and then the polylactic acid solution was mixed with the prepared 4.8wt% polyvinyl alcohol aqueous solution (the volume ratio of the polylactic acid solution to the polyvinyl alcohol solution was 1:25), at 20 °C The emulsification stirring was carried out under the following conditions, the stirring rate was 500 r / min, and the stirring time was 40 min to obtain an O / W emulsion. Then the emulsion water bath was heated to 40 °C, and after stirring at a low speed (60 rpm) for 12 h, the dichloromethane was basically completely volatilized, and the emulsion solidified into microspheres and precipitated. After the solidification of the microspheres is completed, the polylactic acid microsphere suspension is wet-screened through a sieve with a specific mesh n...

Embodiment 2

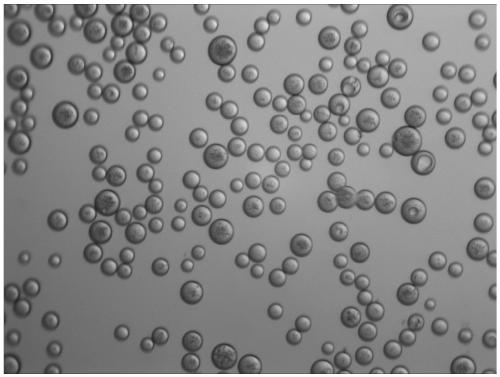

[0071] Dissolve racemic polylactic acid (PDLLA) with a molecular weight of 80,000 in dichloromethane to prepare a polylactic acid solution with a concentration of 25 wt%, and then add polyethylene glycol (PEG- 400) as a porogen, and then mixed the polylactic acid solution with the prepared 5.0wt% polyvinyl alcohol aqueous solution (the volume ratio of the polylactic acid solution to the polyvinyl alcohol solution was 1:40), at 20 °C The emulsification and stirring were carried out at a temperature of 400 r / min and the stirring time was 30 min to obtain an O / W emulsion. Then the emulsion water bath was heated to 40 °C, and after stirring at a low speed (60 rpm) for 16 h, the dichloromethane was basically completely volatilized, and the emulsion solidified into microspheres and precipitated. After the solidification of the microspheres is completed, the polylactic acid microsphere suspension is wet-screened through a sieve with a specific mesh number, and the microspheres with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com