Concrete pouring device for highway construction

A technology for concrete and roads, applied in roads, buildings, roads, etc., can solve the problems of reduced road bearing capacity, affecting molding quality, and large vibrator volume, so as to reduce negative impacts, improve exhaust effects, and improve pouring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

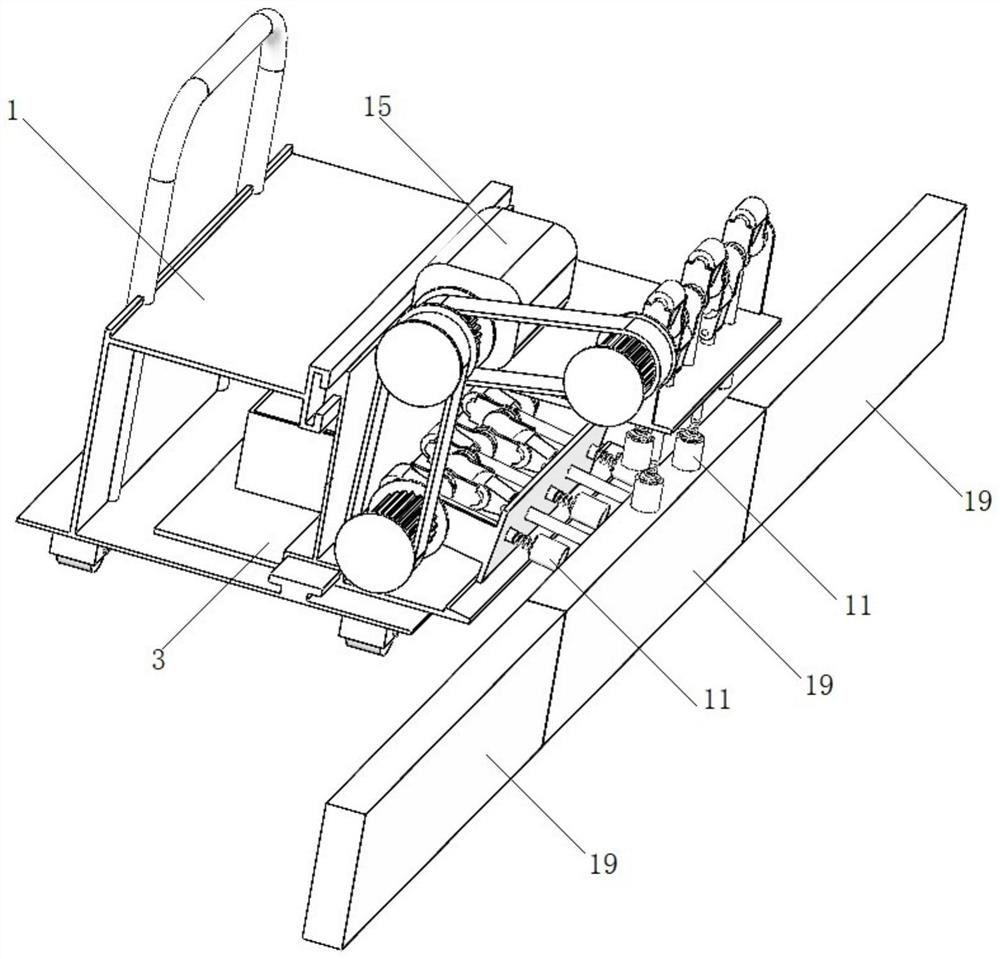

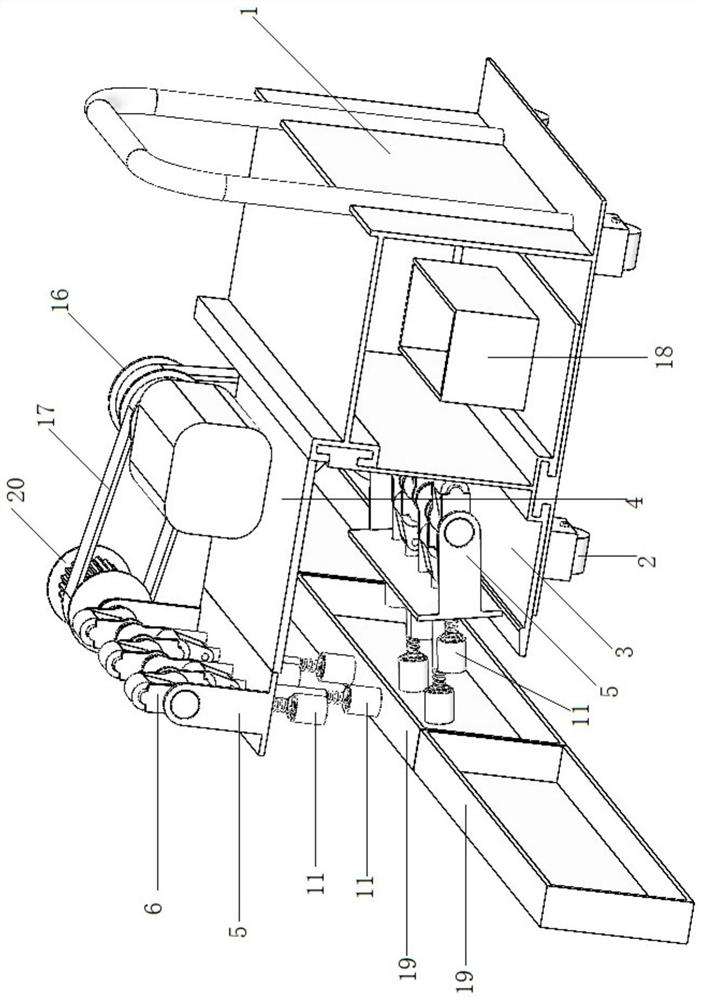

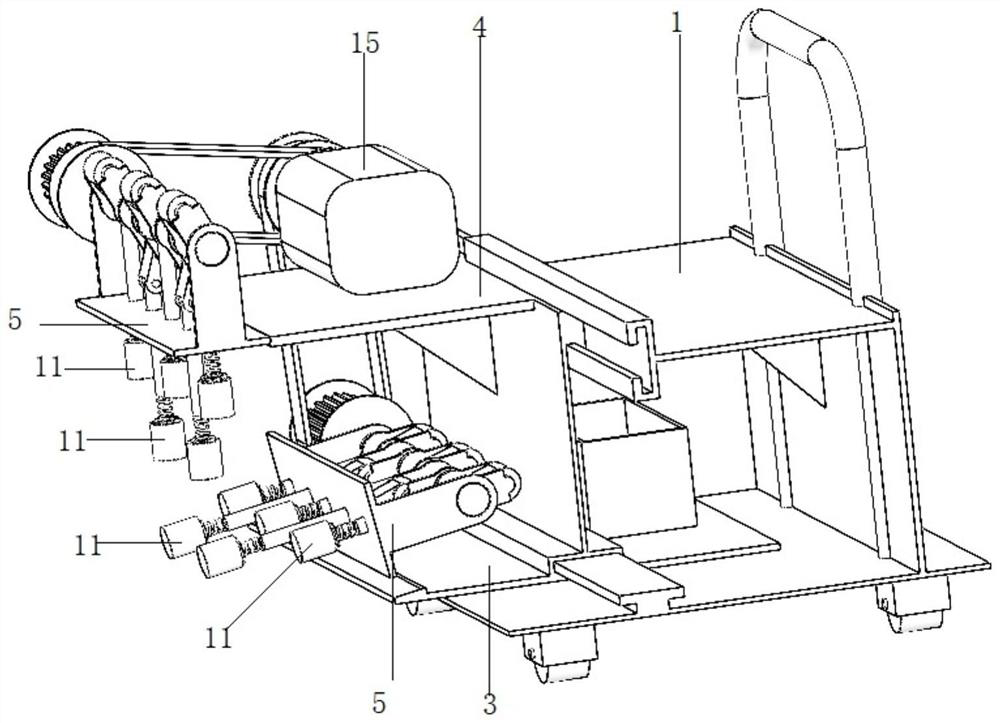

[0026] Such as Figure 1-9 As shown, a concrete pouring device for road construction includes a trolley 1 and a knocking mechanism; a mounting bracket is installed slidingly on the top of the trolley 1 along the left and right directions; the mounting bracket includes a lower bottom plate 3 and an upper top plate 4; the bottom plate 3 and the top plate 4 is equipped with knock mechanism respectively; Described knock mechanism comprises guide bracket 5, crankshaft 6, connecting rod 7, push rod 8, knock head 11 and driven wheel 20; The left and right sides of 5 are rotationally connected; the right end of crankshaft 6 is fixedly installed with driven wheel 20; crankshaft 6 includes a plurality of connecting rod 7 journals; The lower ends are all rotatably connected to a push rod 8; a plurality of guide holes 14 are provided on the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com