Sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial unit, composite structure and preparation method

A technology of acoustic metamaterials and composite structures, applied in the direction of sounding instruments, stringed instruments, instruments, etc., can solve the problem of airtight working bandwidth, etc., and achieve the effects of enhanced work stability, strong market competitiveness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

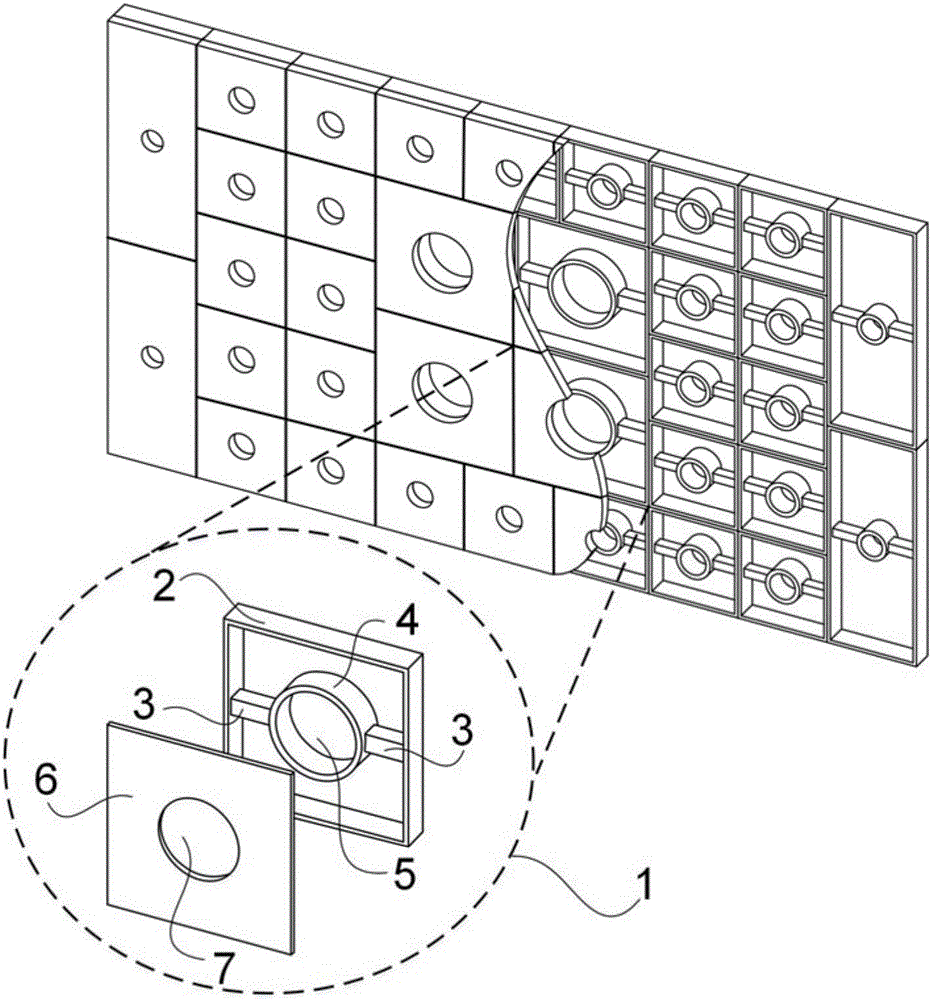

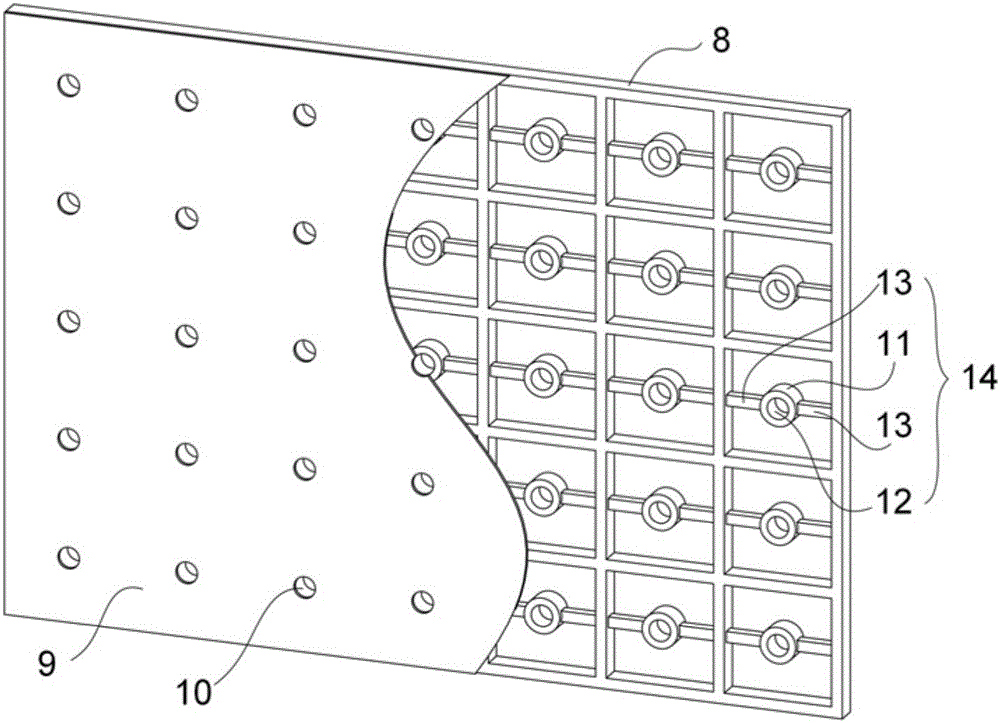

[0142] Example 1 Preparation and Performance Measurement of Basic Acoustic Metamaterial Plate

[0143] Attached below Figure 2-8 The preparation and performance measurement of basic acoustic metamaterial panels are described.

[0144] 1. Preparation of basic acoustic metamaterial plate samples

[0145] Milled using FR-4 fiberglass as figure 2 A frame (8) with a width of 2mm is shown, which contains a series of acoustic metamaterial structural units (14) with the same geometric shape, each unit is a square with an inner side length of 27mm, an outer side length of 29mm, and a thickness of 5mm; also made of FR-4 glass fiber such as figure 2 As shown in the constraining body with holes (11), the frame (8) and the constraining body with holes (11) are rigidly connected by double-arm connecting rods (13), and the specific connection method of the two is integrally formed (milling process) , wherein the diameter of the outer contour of the constrained body (13) with holes is ...

Embodiment 2

[0158] Example 2 Preparation and Performance Measurement of Light and Thin Acoustic Metamaterial Plate

[0159] 1. Preparation of light and thin acoustic metamaterial plate samples

[0160] Such as Figure 9 As shown, a frame (32) with a width of 3 mm and a thickness of 1.5 mm is made by laser cutting with Q235A grade ordinary carbon steel. The frame contains a series of acoustic metamaterial structural units (38) with the same geometric shape, each The unit is a square with an inner side length of 35 mm; the same Q235A grade ordinary carbon steel is used to make a constraining body (35) with holes through laser cutting, and the frame (32) and the constraining body (35) with holes are connected through the double-arm connecting rod (37) Rigid connection, the specific connection mode of the two is integrally formed, wherein the outer contour diameter of the constrained body (35) with holes is 12mm, and the diameter of the upper hole 36 is 7mm, the constrained body (35) and the...

Embodiment 3

[0163] Example 3 Preparation and Performance Measurement of Acoustic Metamaterial Plates Containing Different Parameter Units

[0164] 1. Fabrication of Acoustic Metamaterial Plates Containing Different Parameter Units

[0165] The structure of the acoustic metamaterial plate formed by the combination of in-plane arrays of different parameter units described in Example 3 is shown as Figure 11 As shown, the structural dimensions of the acoustic metamaterial structural units as the basic elements of the array are not exactly the same, and the diameters of the constrained body with holes inside and the diameter of the holes on the constrained body are different. Taking an acoustic metamaterial structural unit (45) as an example, the double-arm connecting rod (44) used to connect the porous constraining body (42) of the acoustic metamaterial structural unit to the frame (39) is as thick as the frame (39) flat, and the structural form is similar to the light and thin acoustic met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com