Tapping screw

A self-tapping screw and screw technology, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of poor effect and insufficient fastening force, and achieve good effect, small screwing resistance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Relatively speaking, the pitch of existing self-tapping screws is too wide, and if a small-diameter self-tapping screw is used, the fastening force is not enough.

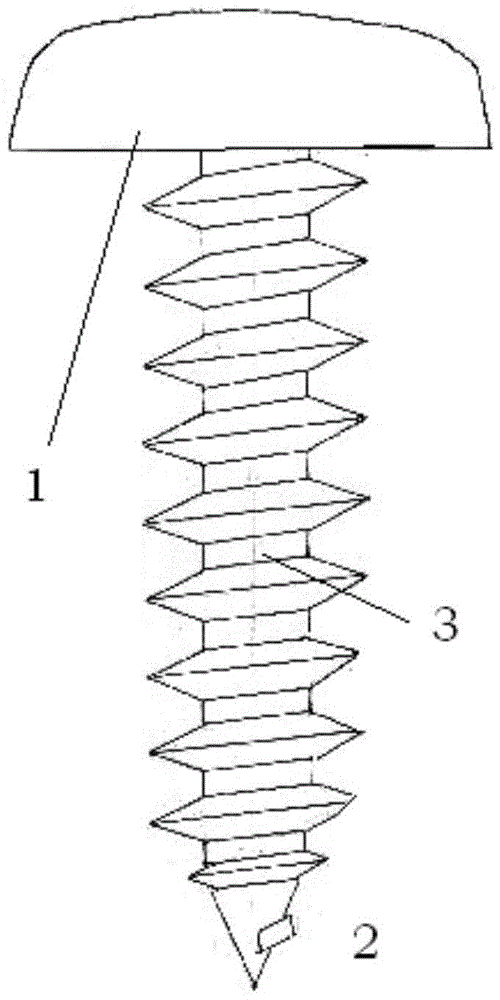

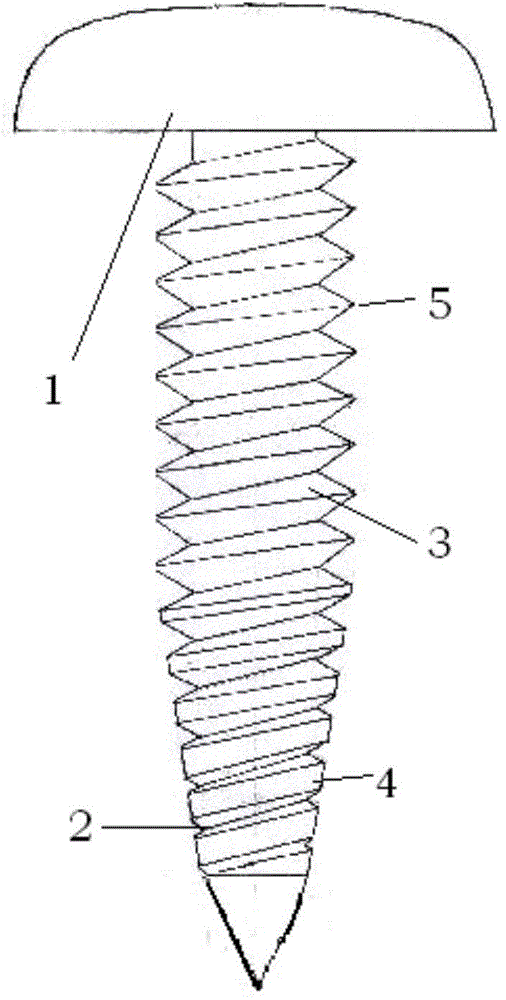

[0017] A self-tapping screw of the present invention, the tip 2 of the screw 1 is extended to reduce the outer diameter, the pitch of the screw thread and the diameter ratio of the middle screw 3 are 1:5.5-9; the tip of the screw is a circular frustum or a conical part. The ratio of the pitch of the screw thread to the diameter of the intermediate screw is especially 1:6-8.

[0018] The cross-section of the tip thread teeth of the screw rod is a bald thread 4 with 2-5 threads, and the thread teeth of the middle screw rod are cutting teeth 5 with 3-7 threads. The cross-section of the tip thread teeth is from bald teeth to the cutting teeth of the middle screw rod. The transition thread with the width of the bald tooth gradually narrows. The transition thread is 2-20, especially 2-8 ( figure 2 Also shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com