Corrugated hose with joint jacket and manufacturing method thereof

A corrugated hose, corrugated pipe technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problem of difficult connection between the joint and the main body of the hose, the separation of the main body of the sheathed hose, and the cracking of the sheath. and other problems, to achieve the effect of preventing distortion, connecting firmly, and protecting the bellows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

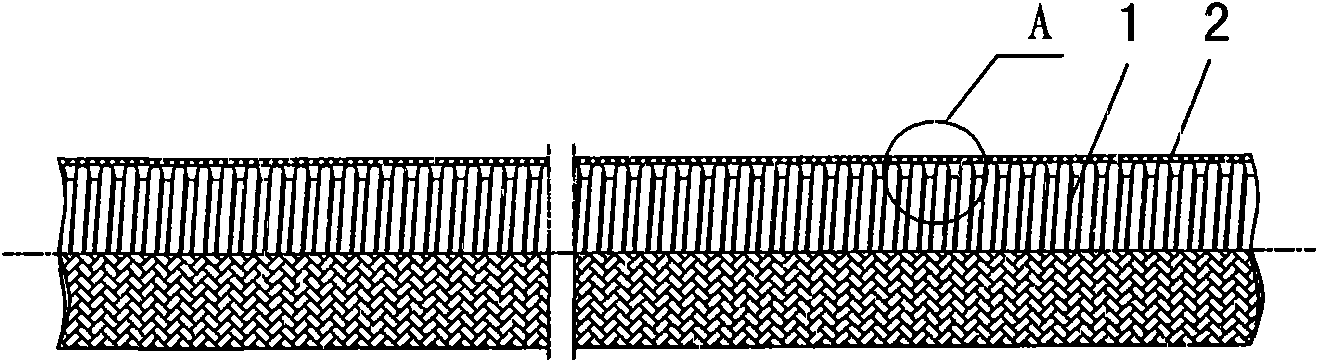

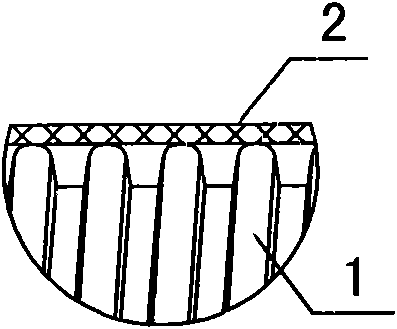

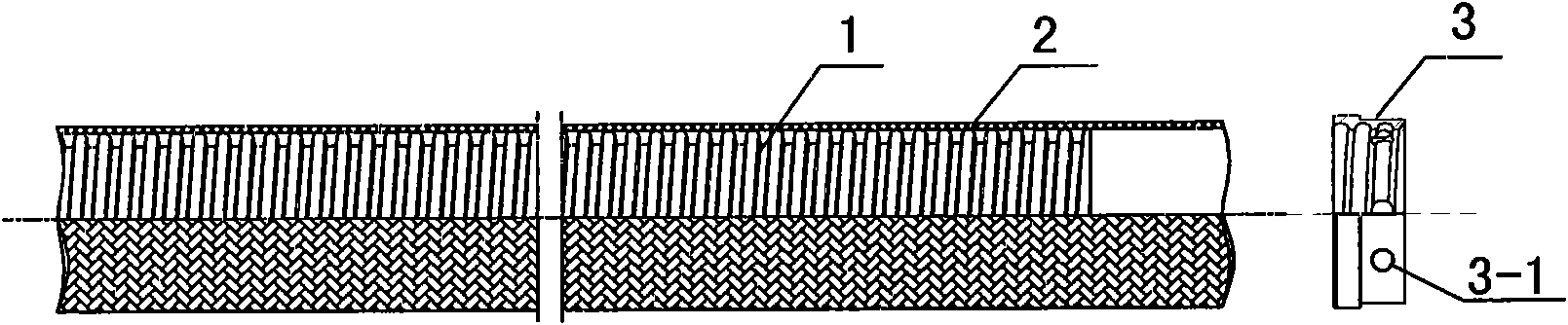

[0020] In this embodiment, the manufacturing process of the corrugated hose with joint sheath is as follows: Figure 1 to Figure 4 Shown:

[0021] 1. Put the braided sheath 2 outside the bellows 1 to form the main body of the hose. The inner diameter of the sheath 2 is adapted to the maximum outer diameter of the bellows 1 (see figure 2 ), the tight sleeve plays a reinforcing role behind the bellows. In order to facilitate the subsequent installation of the collar, the end of the sheath 2 protrudes beyond the end of the bellows 1 (see image 3 );

[0022] 2. Put the collar 3, which has an internal thread matching the corrugation of the bellows, and has radial perforations 3-1 distributed at intervals, on the end of the sheath beyond the bellows, and then screw it to the end of the sheath. onto the hose body of sleeve 1 and the end of the hose body unscrewed from the collar (see Figure 4 ); due to the good shrinkage of the braided sheath, it is easy to pass through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com