Asepsis environment-protecting polycinyl chloride bottle cap sealant and method for preparing same

A polyvinyl chloride, non-toxic and environmentally friendly technology, used in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of high production cost of liquid sealants and expensive plasticizers, and achieve increased dosage and sealing effect. Good, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

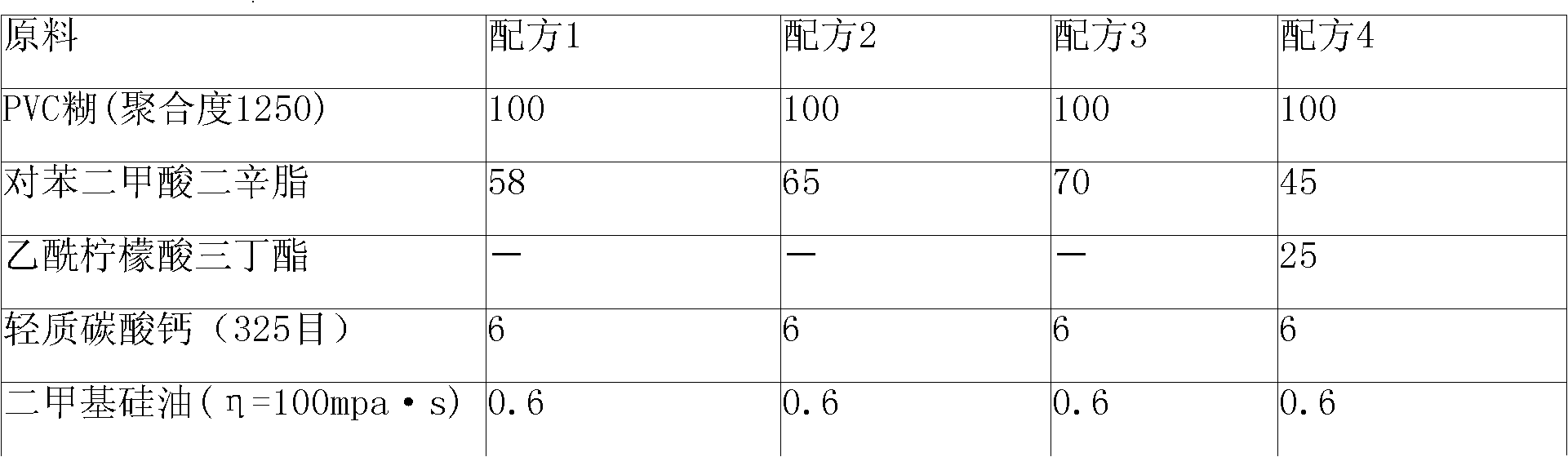

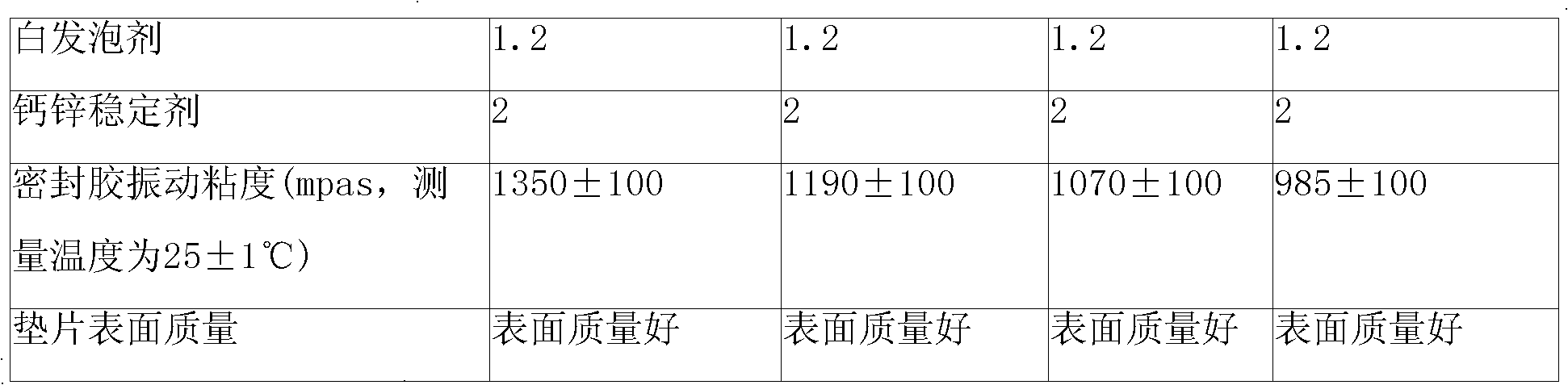

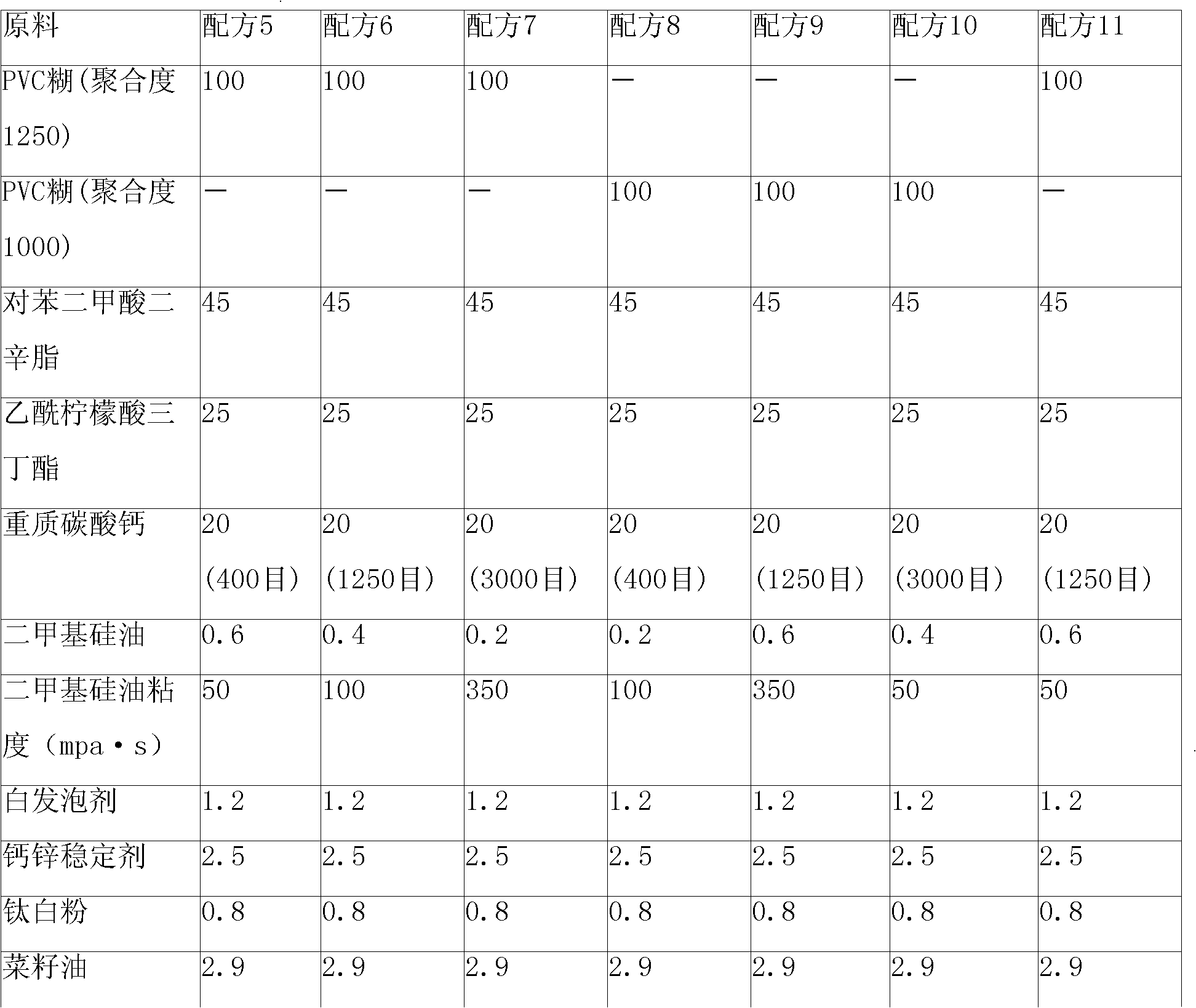

[0023] Embodiment 1: Raw materials: polyvinyl chloride paste resin 100g (polymerization degree 1250), dioctyl terephthalate 45g, acetyl tributyl citrate 25g, heavy calcium carbonate 20g (particle size 1250 orders), calcium-zinc stable Agent 2.5g, white foaming agent: sodium bicarbonate 1.2g, titanium dioxide 0.8g, simethicone oil 0.6g (viscosity: 50mpa s), rapeseed oil 2.9g

[0024] Preparation method: First, dry heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent and titanium dioxide in an environment of 40°C for 2.5 hours, and mix dioctyl terephthalate and acetyl tributyl citrate Uniformly used as a plasticizer, divided into three parts according to 30%, 50% and 20% of the total plasticizer, take 30% of the plasticizer, stir for 1 minute at a speed of 230 rpm, and then stir at a speed of 140 rpm Minute speed, while stirring, add white foaming agent, titanium dioxide, calcium-zinc stabilizer, heavy calcium carbonate, then stir at 860 rpm for 20min, at 140 rp...

Embodiment 2

[0032] Embodiment 2: raw material: polyvinyl chloride paste resin 90g (polymerization degree 1200), dioctyl terephthalate 50g, acetyl tributyl citrate 30g, heavy calcium carbonate 15g (particle size 1250 orders), calcium-zinc stable 3g agent, 1.2g white foaming agent, 0.6g titanium dioxide, 0.5g simethicone oil (viscosity: 50mpa·s) and 2.5g rapeseed oil

[0033]Preparation method: First, dry heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent and titanium dioxide in an environment of 40°C for 3 hours, and mix dioctyl terephthalate and acetyl tributyl citrate Uniformly used as a plasticizer, divided into three parts according to 30%, 40% and 30% of the total plasticizer, take 30% of the plasticizer, stir at a speed of 250 rpm for 0.5 minutes, and then stir at a speed of 120 rpm Minute speed, while stirring, add white foaming agent, titanium dioxide, calcium-zinc stabilizer, heavy calcium carbonate, then stir at a speed of 900 rpm for 15 minutes, at a speed of ...

Embodiment 3

[0034] Embodiment 3: Raw materials: polyvinyl chloride paste resin 110g (polymerization degree 1200), dioctyl terephthalate 40g, acetyl tributyl citrate 20g, heavy calcium carbonate 25g (particle size 1250 orders), calcium-zinc stable Agent 2g, white foaming agent 1g, titanium dioxide 1g, simethicone 0.8g (viscosity: 50mpa·s) and rapeseed oil 3.5g

[0035] Preparation method: First, dry heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent and titanium dioxide in an environment of 40°C for 4 hours, and mix dioctyl terephthalate and acetyl tributyl citrate Uniformly used as a plasticizer, divided into three parts by 20%, 60% and 20% of the total amount of plasticizer, get 20% plasticizer, stir at 200 rpm for 1.5 minutes, then stir at 160 rpm Minute speed, while stirring, add white foaming agent, titanium dioxide, calcium-zinc stabilizer, heavy calcium carbonate, then stir at 800 rpm for 25 minutes, at 160 rpm, while stirring Add polyvinyl chloride paste resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com