Belt wheel disc

A pulley and wheel disc technology, applied in the field of mechanical parts, can solve the problems of inconvenient installation and transportation, affect the transmission effect, and the pulley is easy to fall off, etc., and achieve good application prospects, convenient transportation and installation, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

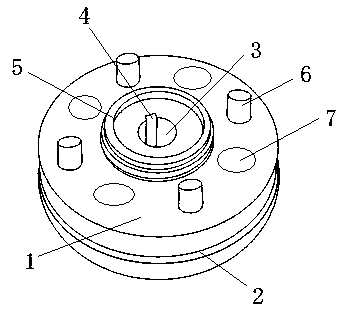

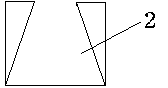

[0015] Such as figure 1 and figure 2 As shown, a belt pulley includes a pulley body 1, a ring-shaped belt placement groove 2 is provided in the middle of the outer wall of the pulley body 1, the cross section of the belt placement groove 2 is an isosceles trapezoid, and the short side is the belt placement groove 2 Opening, the width of the belt is slightly larger than the width of the short side of the isosceles trapezoid, which is the same as the width of the long side of the isosceles trapezoid. Due to the elasticity of the belt, it can be placed in the belt placement groove 2 by force. This design can prevent the belt from rotating at high speed. In case of falling off, to improve the reliability, the middle part of the mounting surface of the roulette body 1 is provided with a driving bearing mounting hole 3, and the hole wall of the driving bearing mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com