Device for automatically cleaning and rinsing heavy equipment and parts

An automatic cleaning, heavy-duty technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of inconvenient loading and unloading of workpieces, troublesome loading and unloading of workpieces, and difficult to use mechanical spreaders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

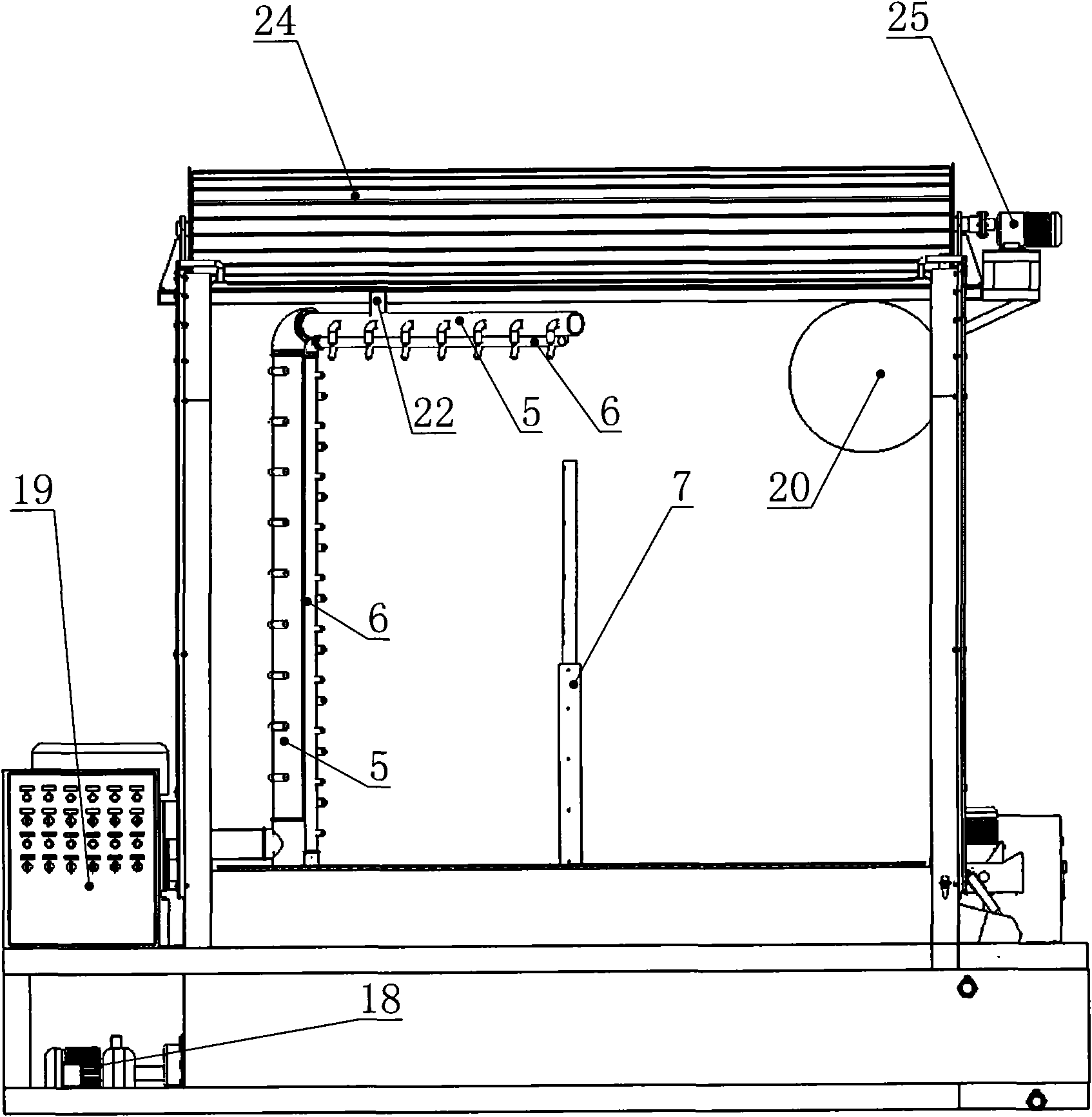

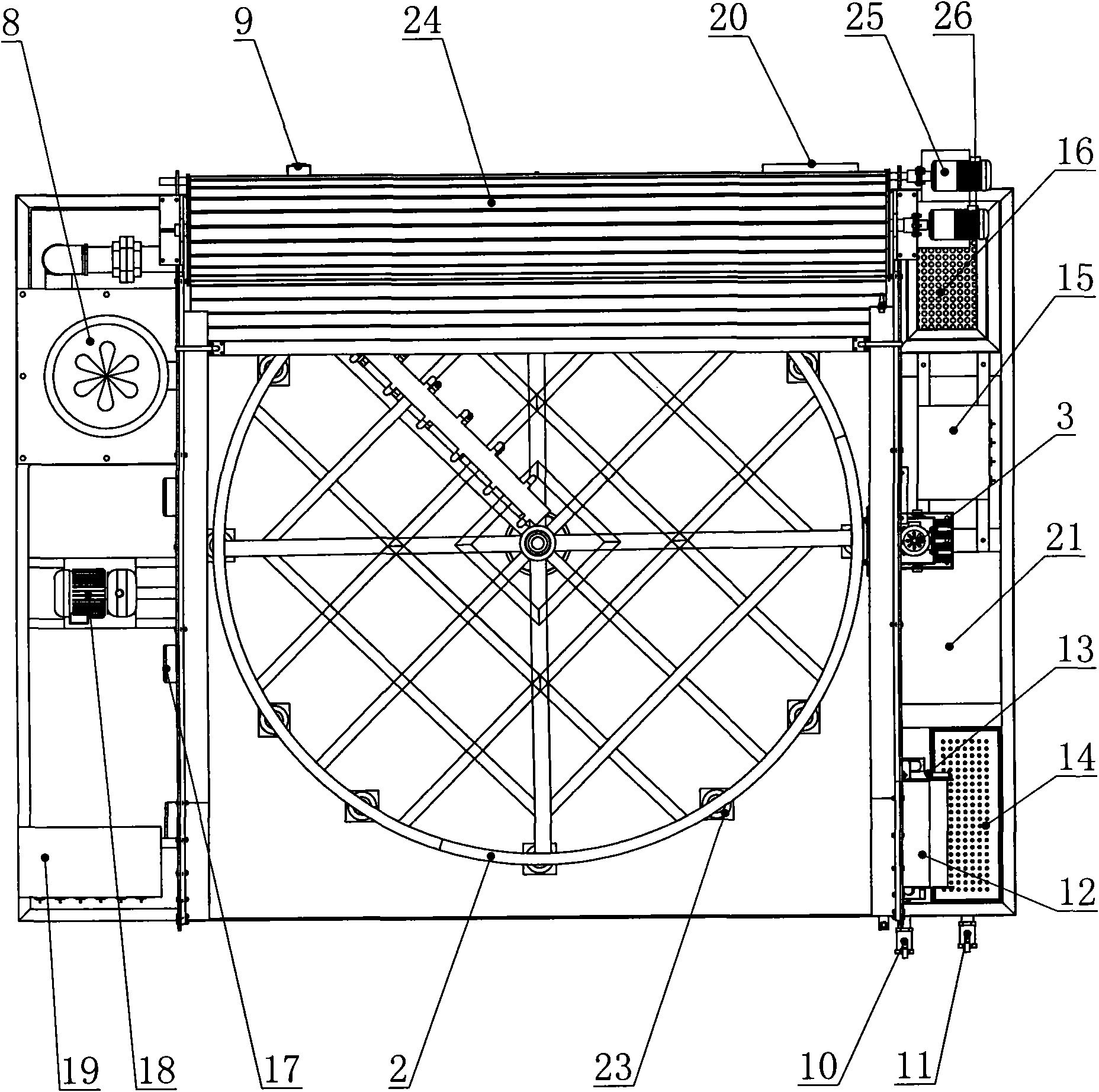

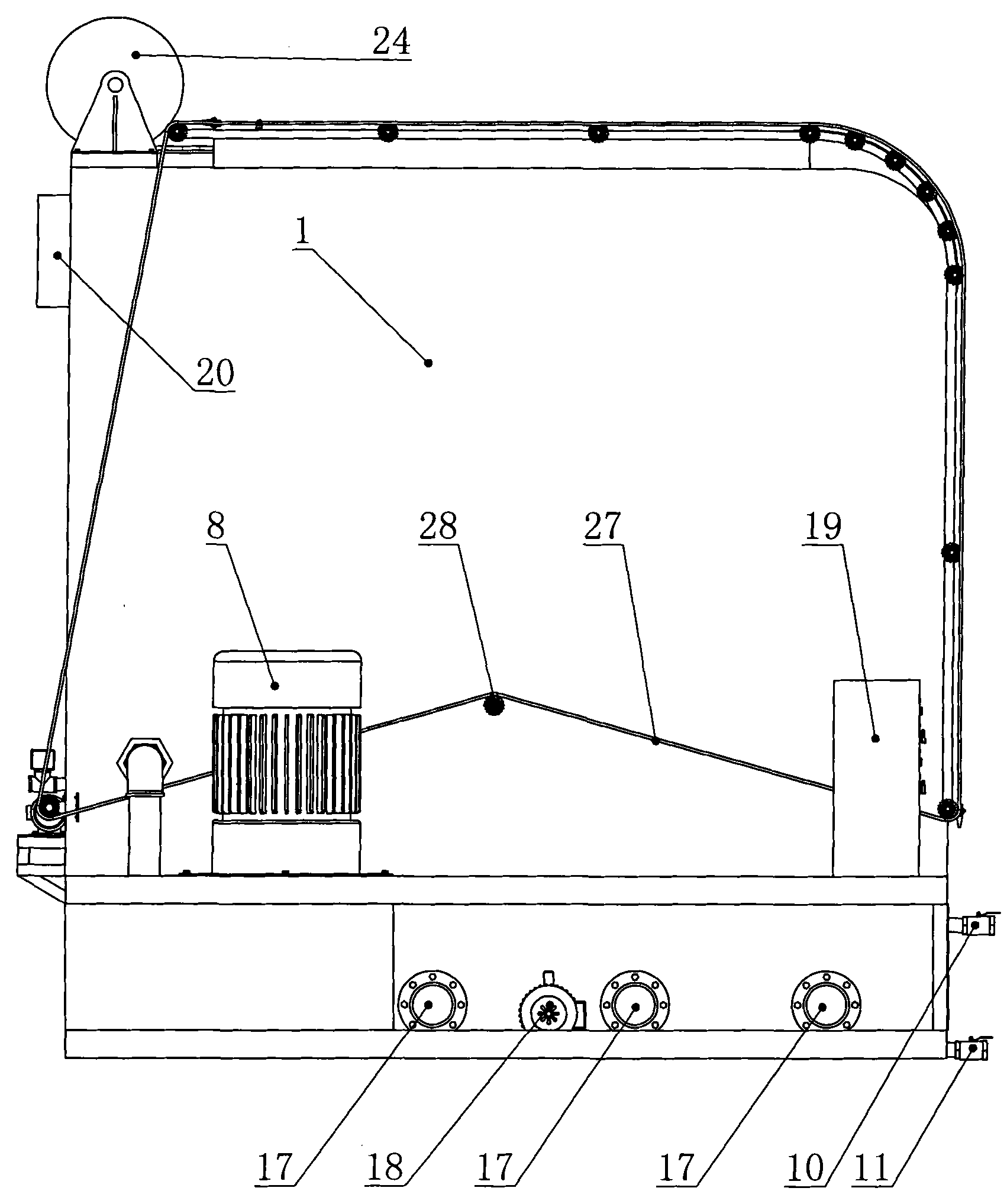

[0017] exist figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, the overall dimensions of the main body of the device (length×width×height) are: 4200mm×3100×3200, the maximum diameter of the object that can be cleaned is 2700mm, and the maximum weight is 30000kg. The main steps of cleaning and rinsing of major equipment and components are as follows:

[0018] 1. Set the heating temperature of the cleaning liquid, start the heating device and the cleaning liquid circulation pump, and when the set temperature is reached, the heating device will automatically stop and keep warm.

[0019] 2. Pour the cleaning agent into the cleaning agent preparation tank in proportion, and the cleaning liquid circulation pump runs to prepare the cleaning liquid.

[0020] 3. Use the mechanical spreader to place the workpiece on the turntable, and start the rolling shutter door to move down and close the device.

[0021] 4. Set the time of cleaning operation and the time of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com