Insertion grouted reinforcing steel bar connecting sleeve and construction method thereof

A steel connecting sleeve and plug-in technology, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of unassembled construction and complicated steel connection construction, and achieve the effect of reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

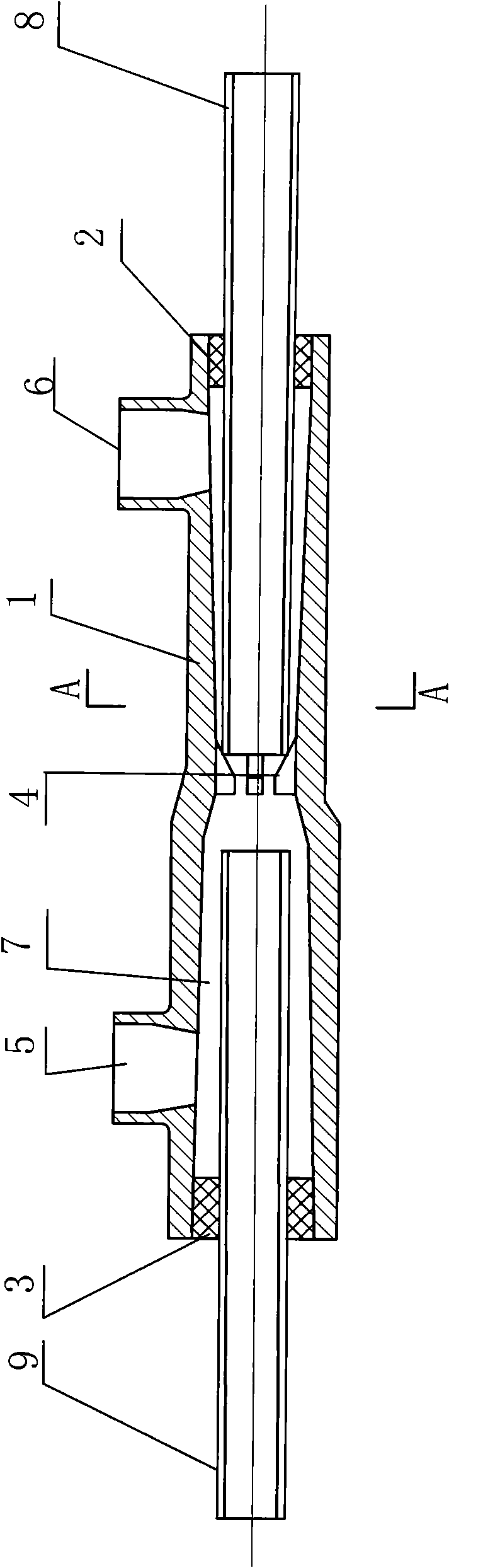

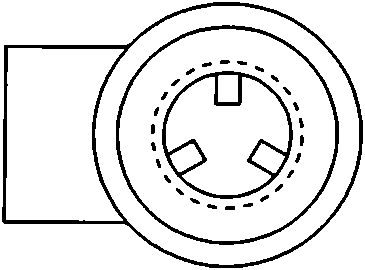

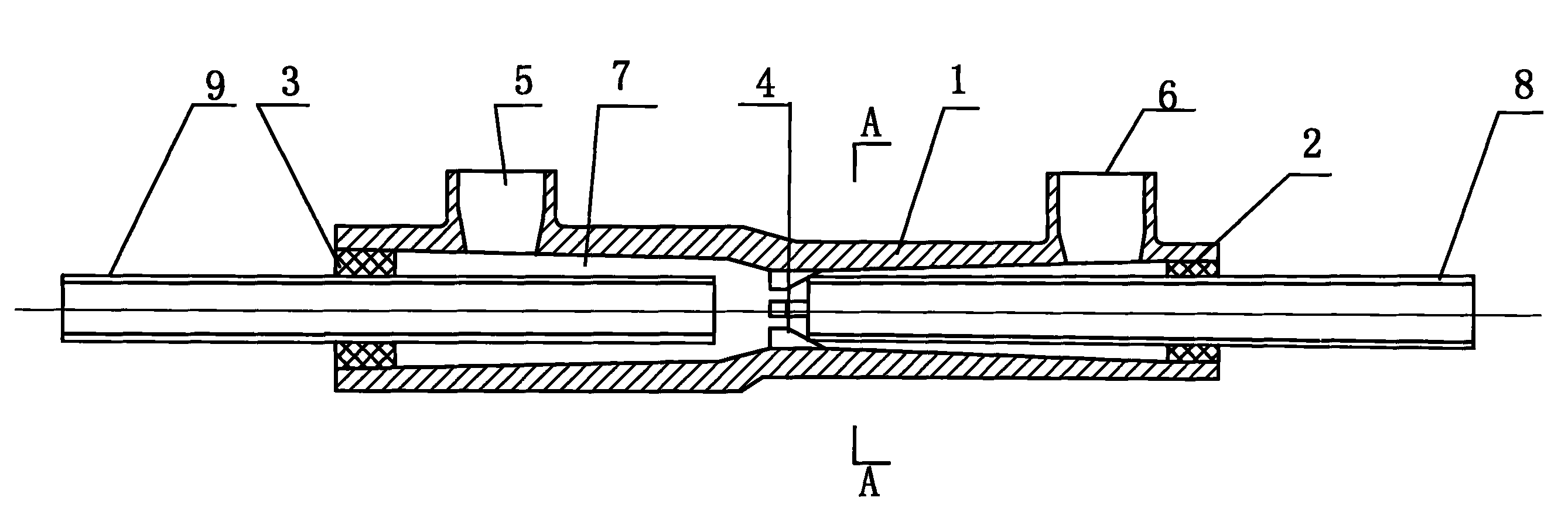

[0020] Plug-in grouting reinforcement connection sleeve, which consists of: sleeve body 1, with a through hole 2 inside the sleeve body 1, elastic rubber sealing rings 3 are installed at both ends of the through hole 2 in the sleeve body, The size of the two ends of the through hole in the sleeve body is different, one end is small and the other end is large, and a group of limit blocks 4 distributed along the inner wall are arranged in the middle of the sleeve body, and the limit block 4 is inserted toward the steel bar There is a slope in the direction, the top of the sleeve body 1 is provided with a grouting hole 5 and an exhaust hole 6 communicating with the inside, the inside ends of the sleeve body have tapered threads, and the sleeve body has a small size The end is connected with the pre-embedded steel bar 8, and the large-size end of the sleeve body is connected and inserted into the steel bar 9.

Embodiment 2

[0022] For the plug-in grouting steel bar connection sleeve described in Example 1, the diameters in the sleeve body are different, the small-sized end is equipped with a small-sized tapered thread, and the large-sized end is equipped with a large-sized tapered thread. Tapered thread, the positions of the limit blocks in the sleeve body are spaced at 120°, and the limit blocks and the sleeve body are integrally cast.

Embodiment 3

[0024] As for the plug-in grouting steel bar connecting sleeve, the circumferential thickness of the elastic rubber sealing ring is larger than the gap between the sleeve and the steel bar, and the inner diameter of the elastic rubber sealing ring is smaller than the outer diameter of the steel bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com