Patents

Literature

31results about How to "Shorten the renovation period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

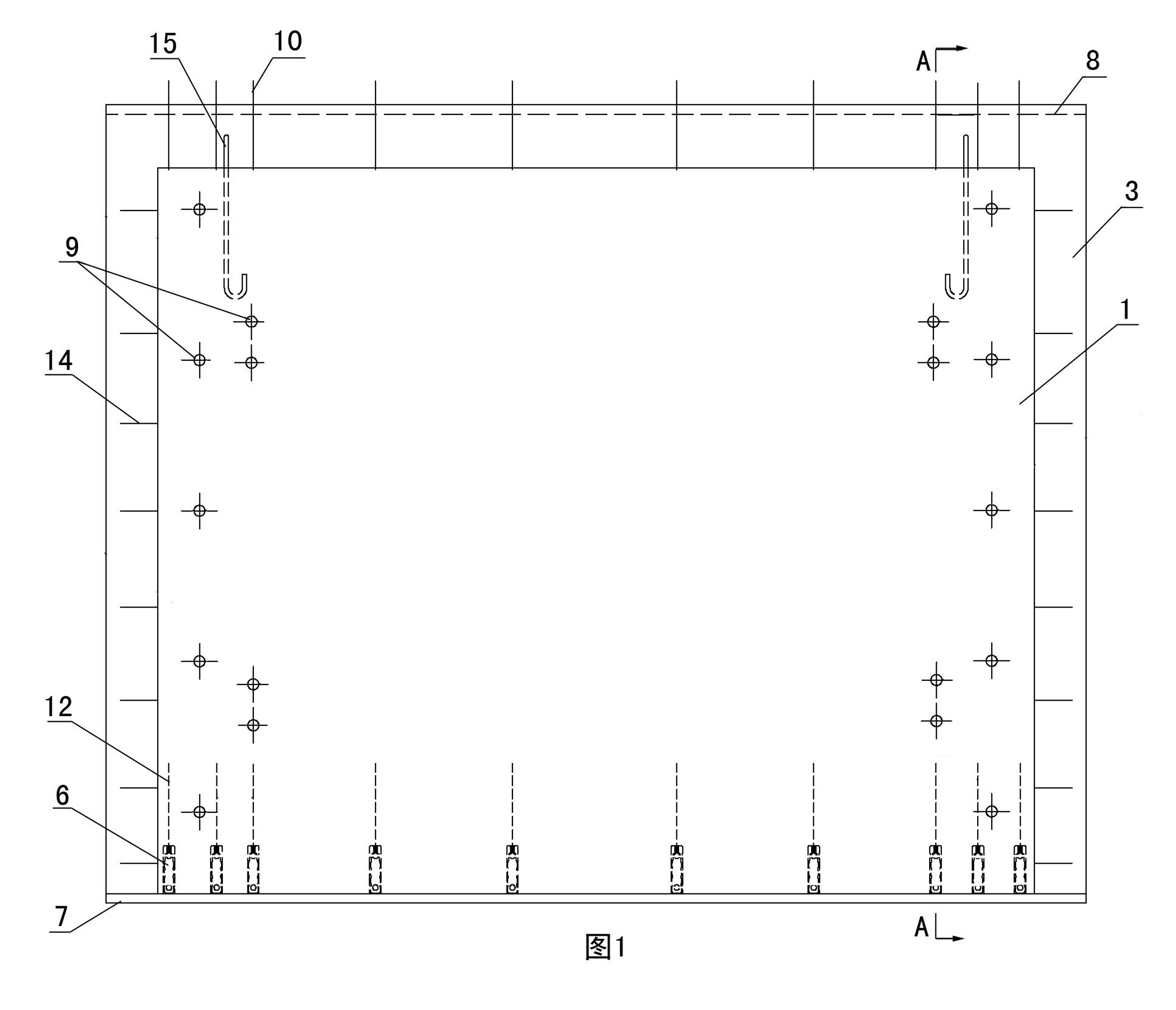

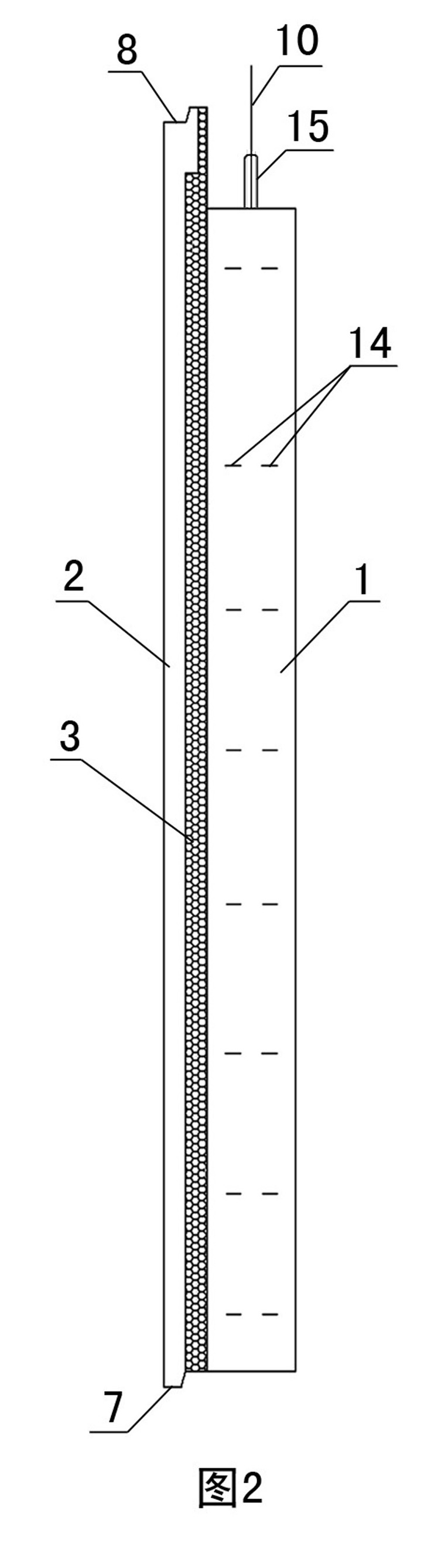

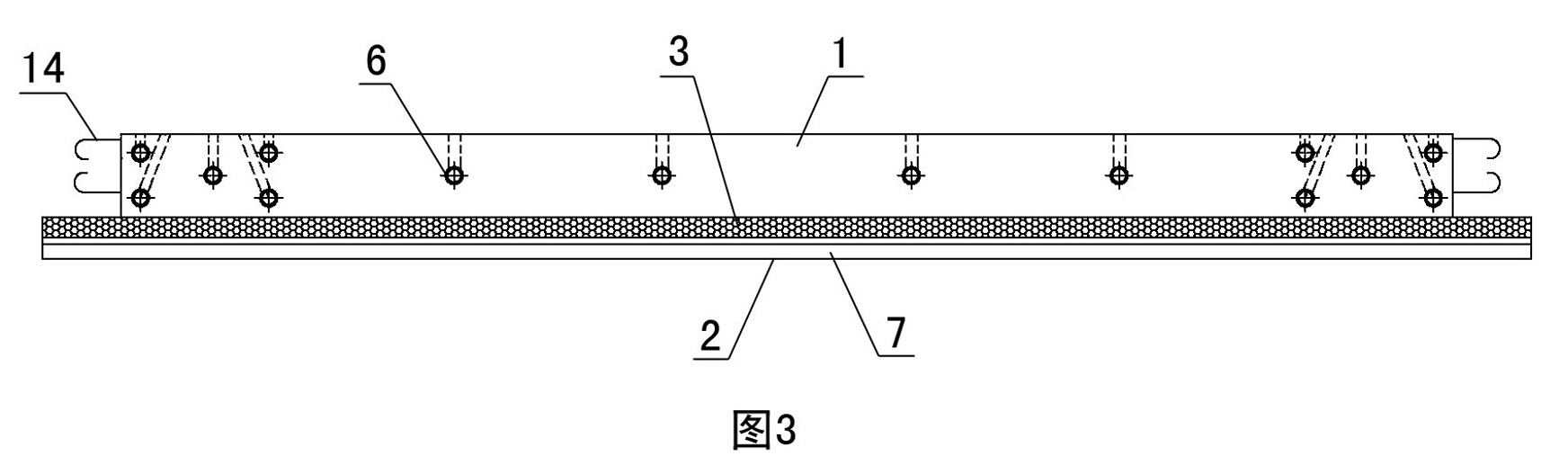

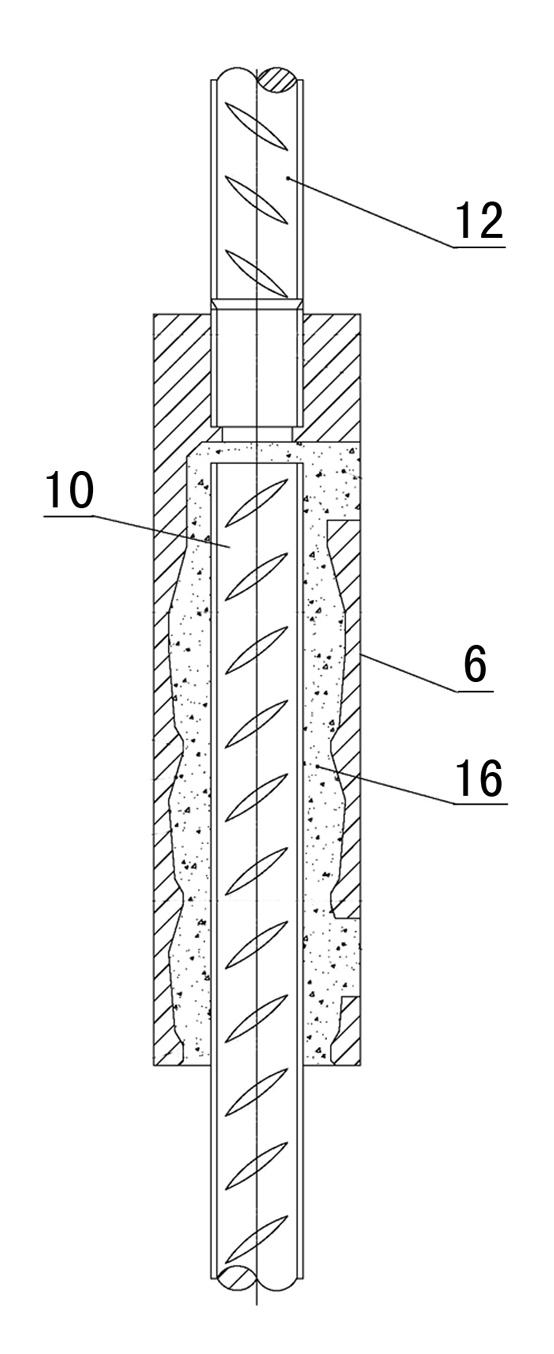

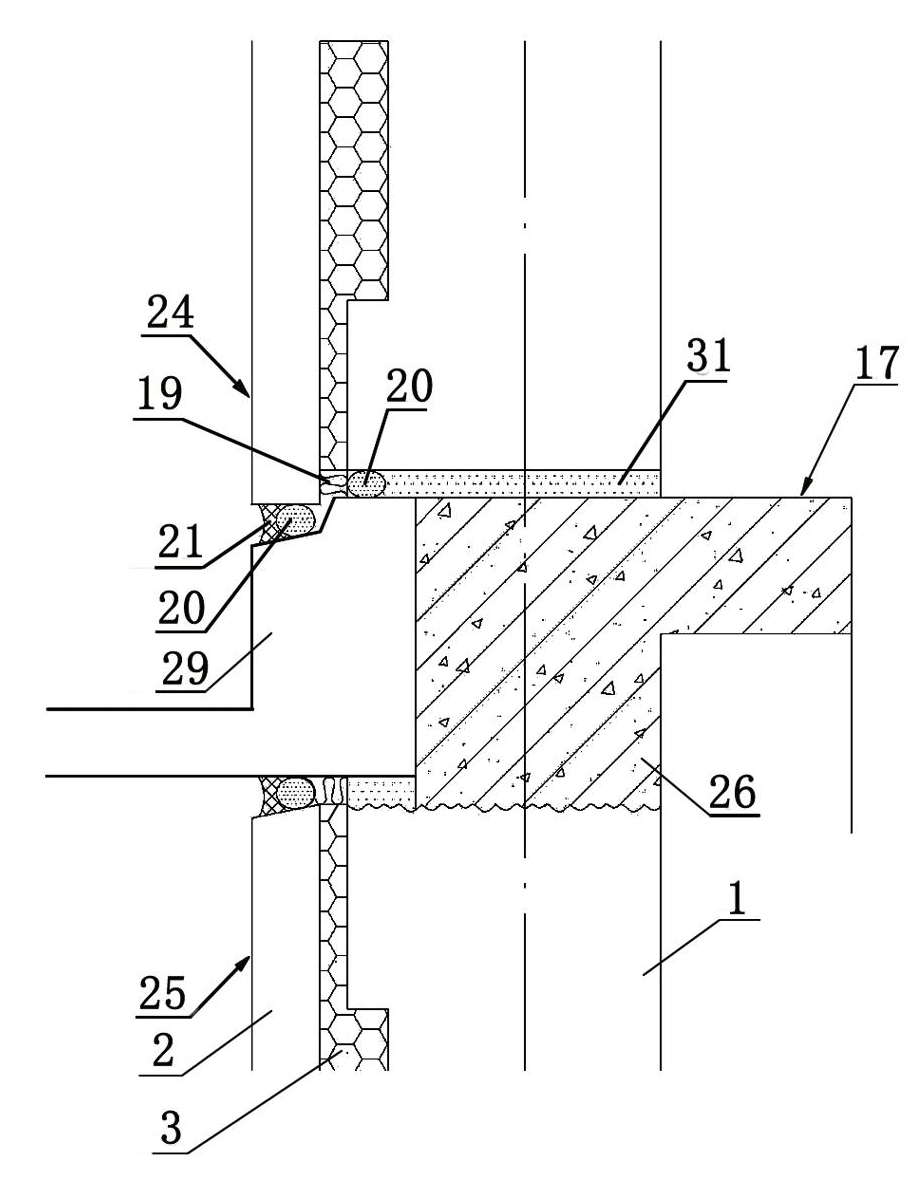

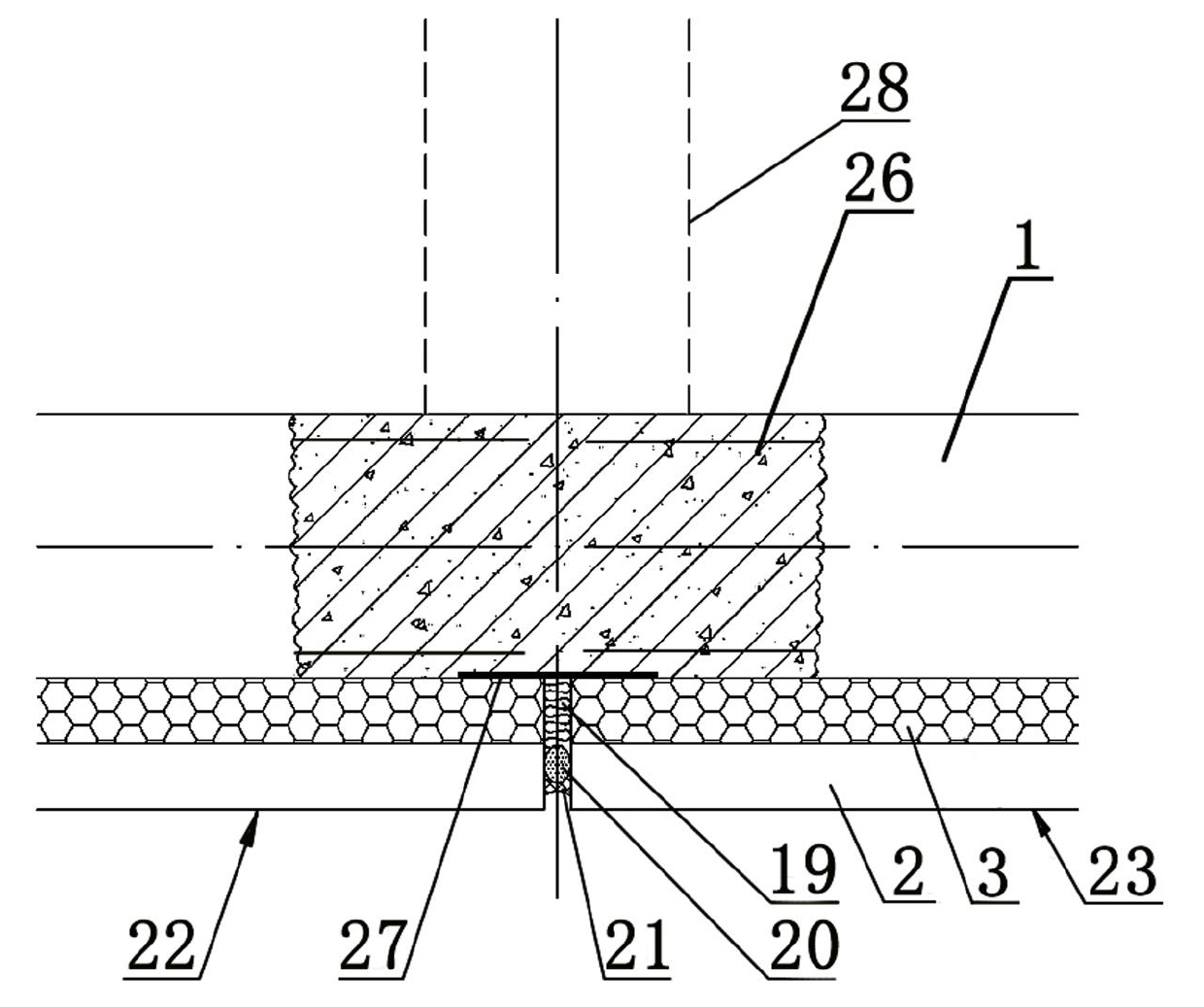

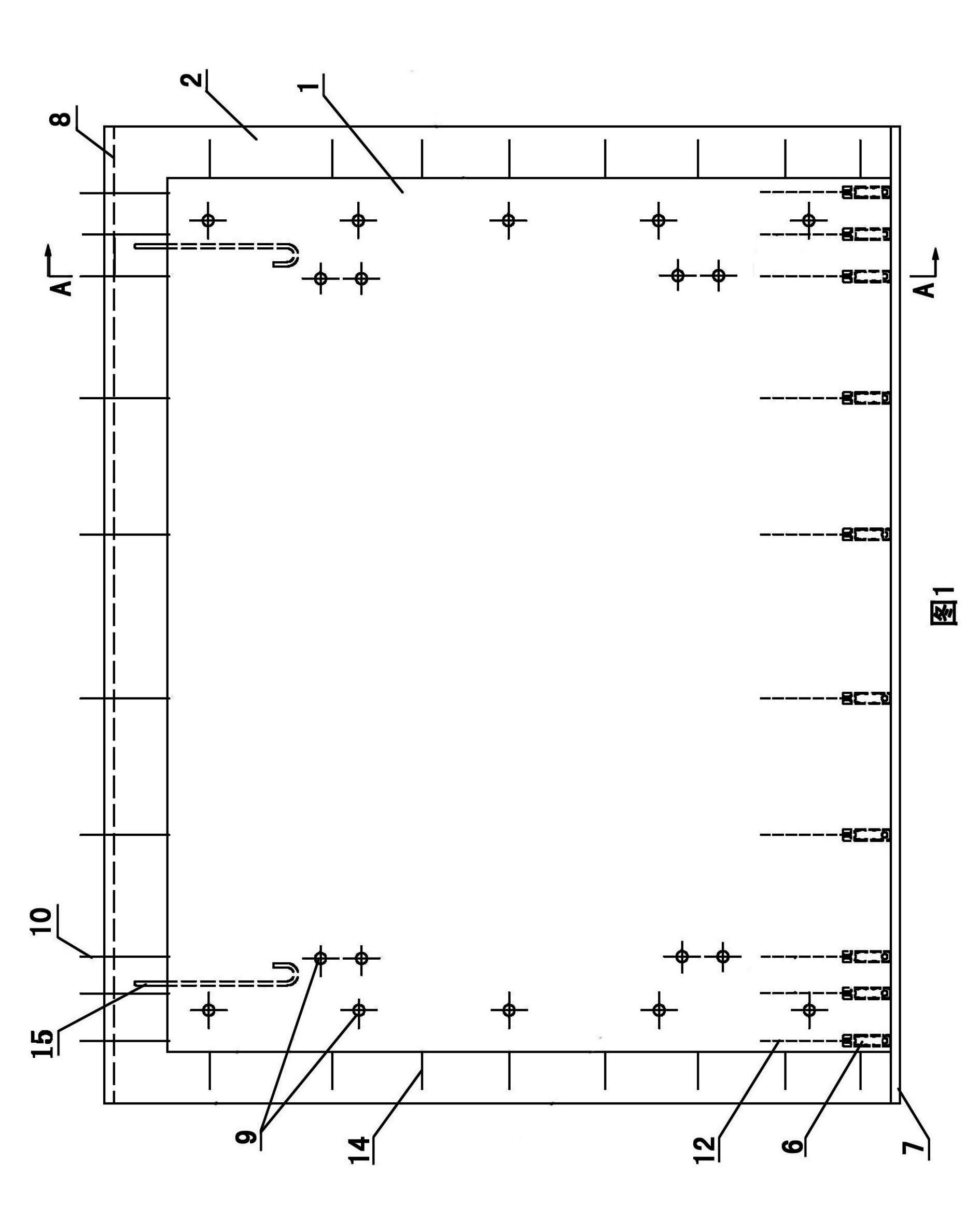

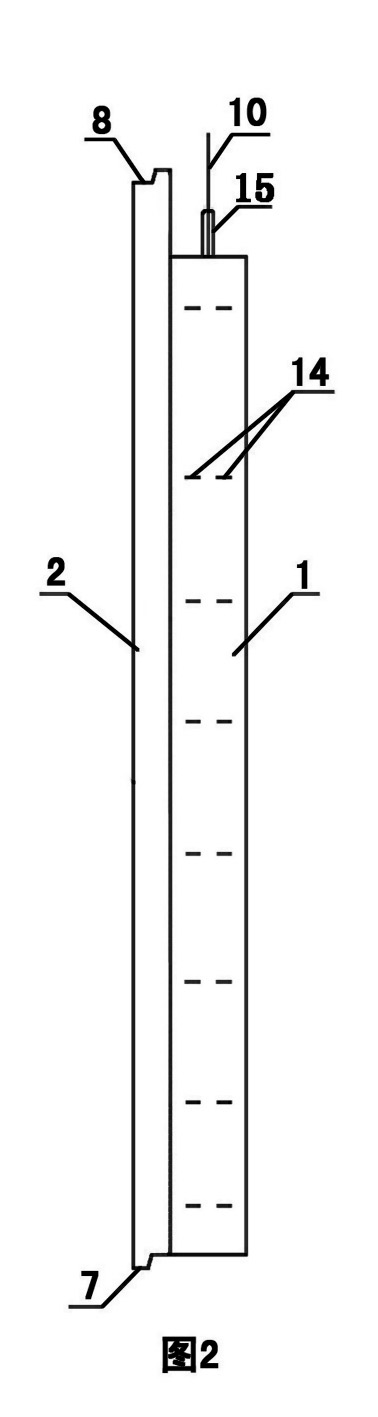

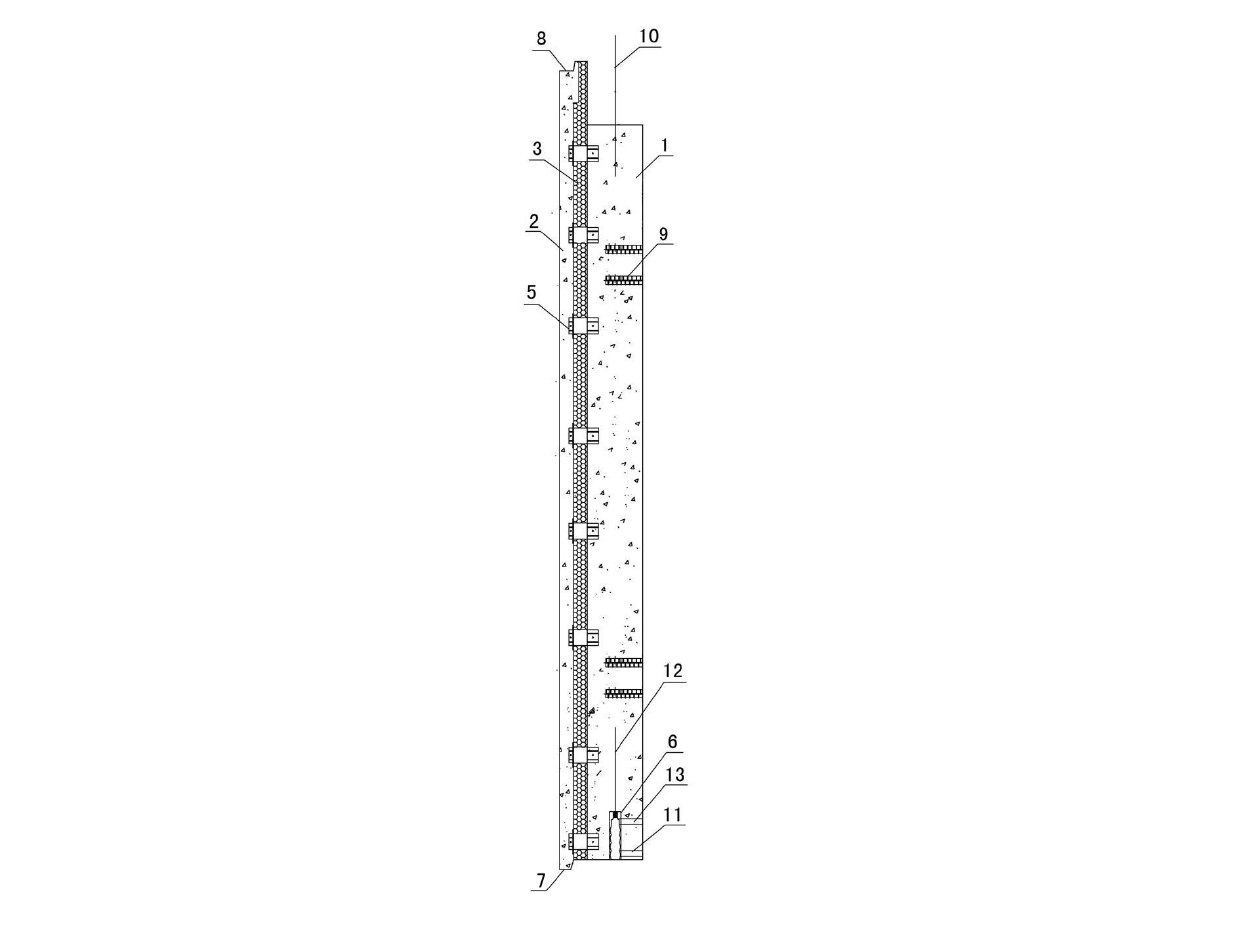

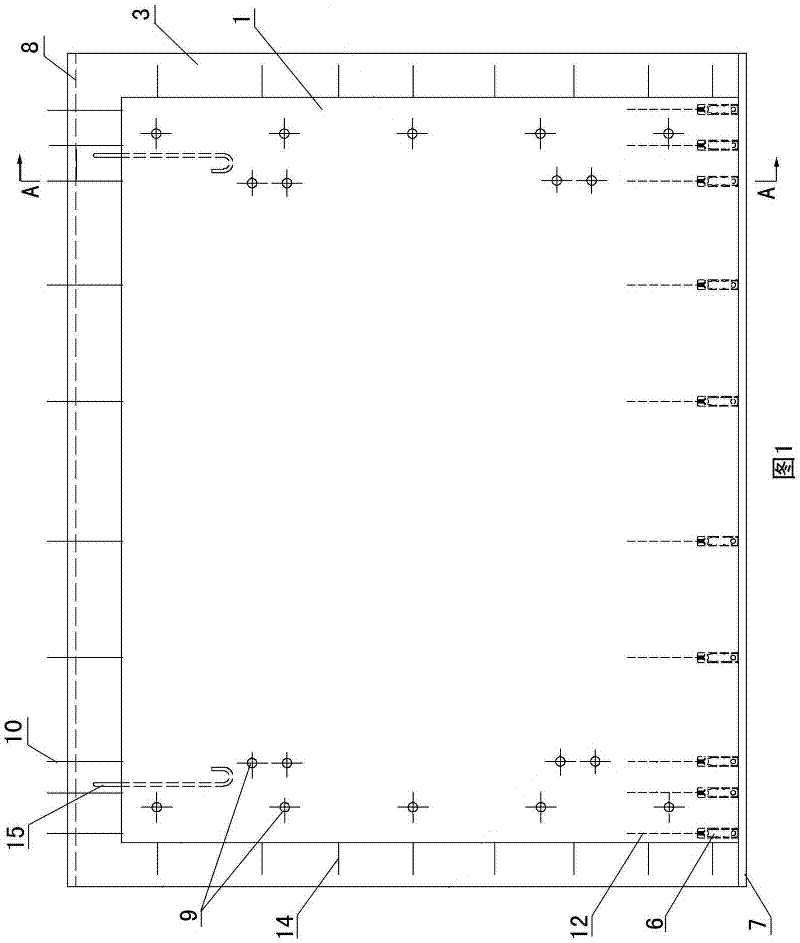

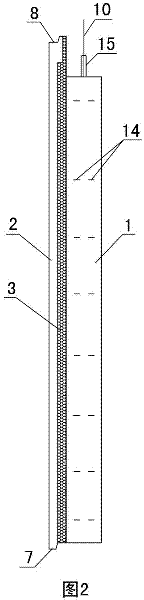

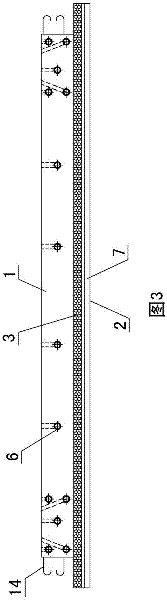

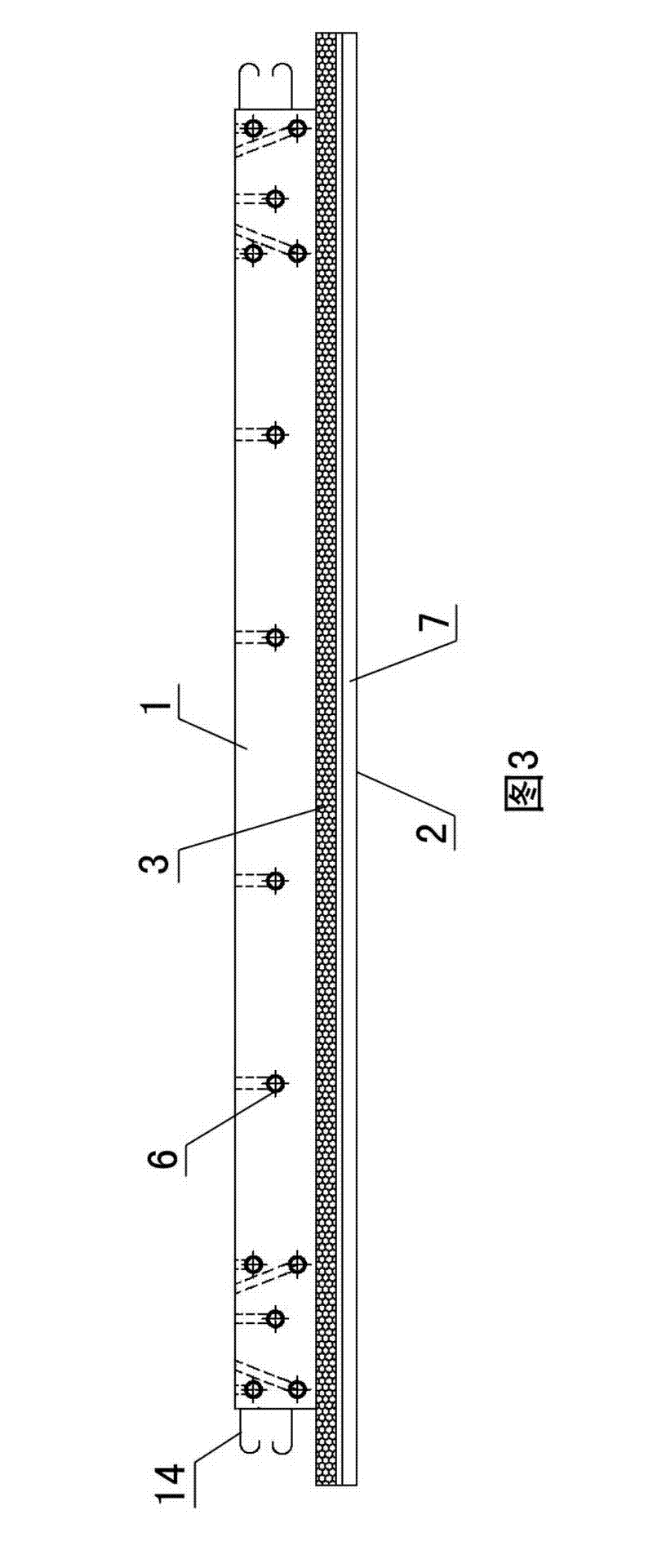

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

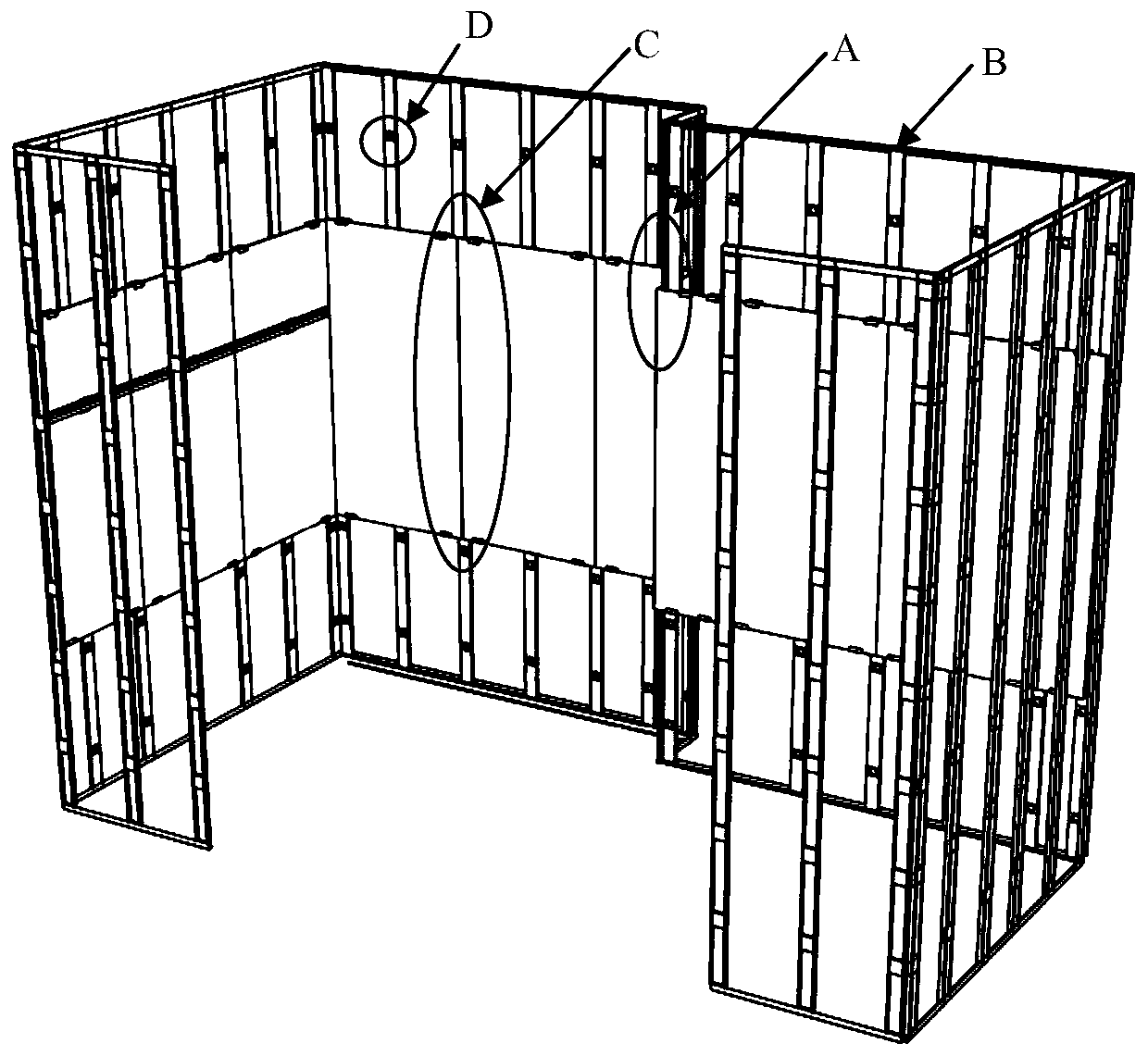

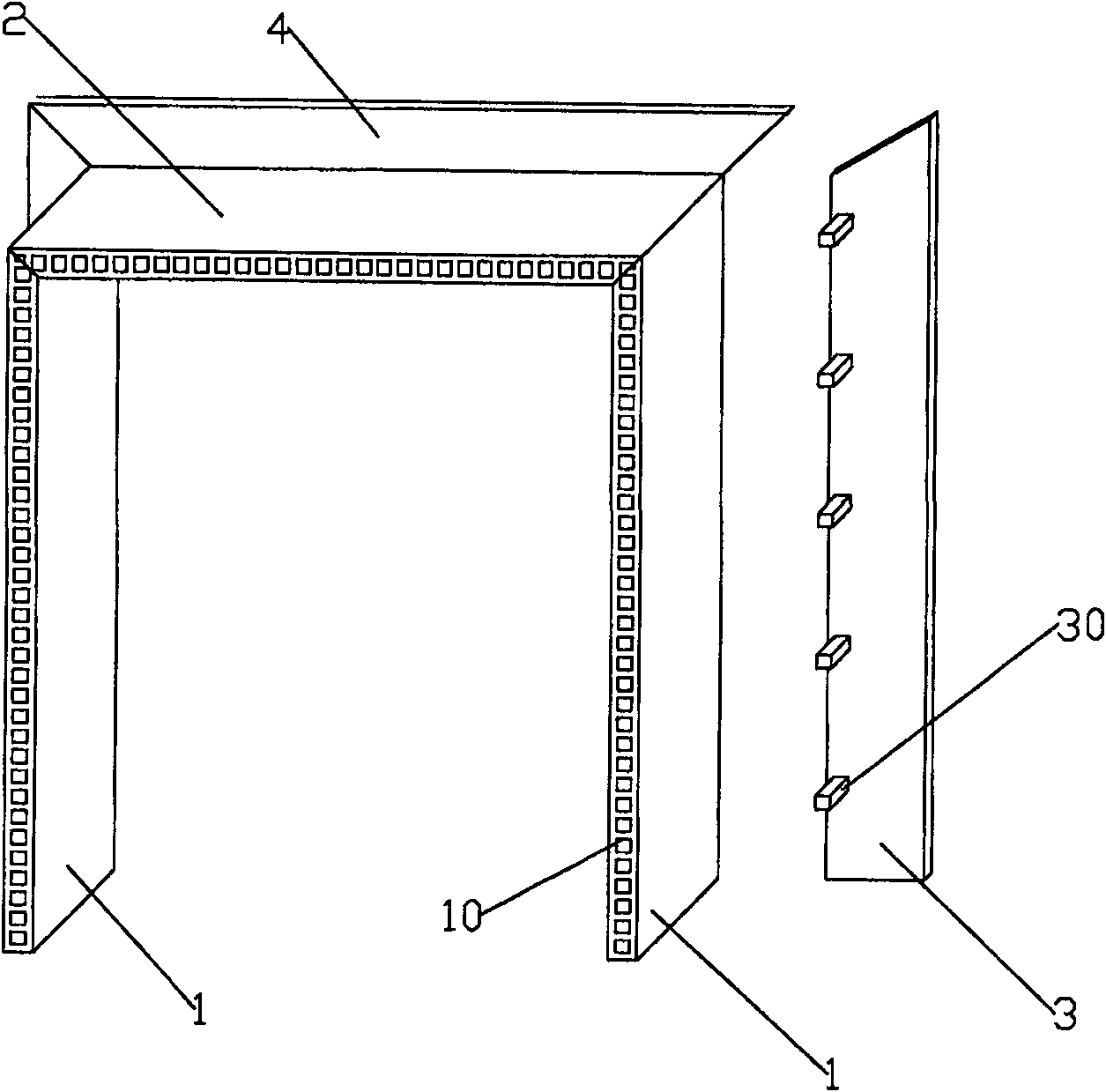

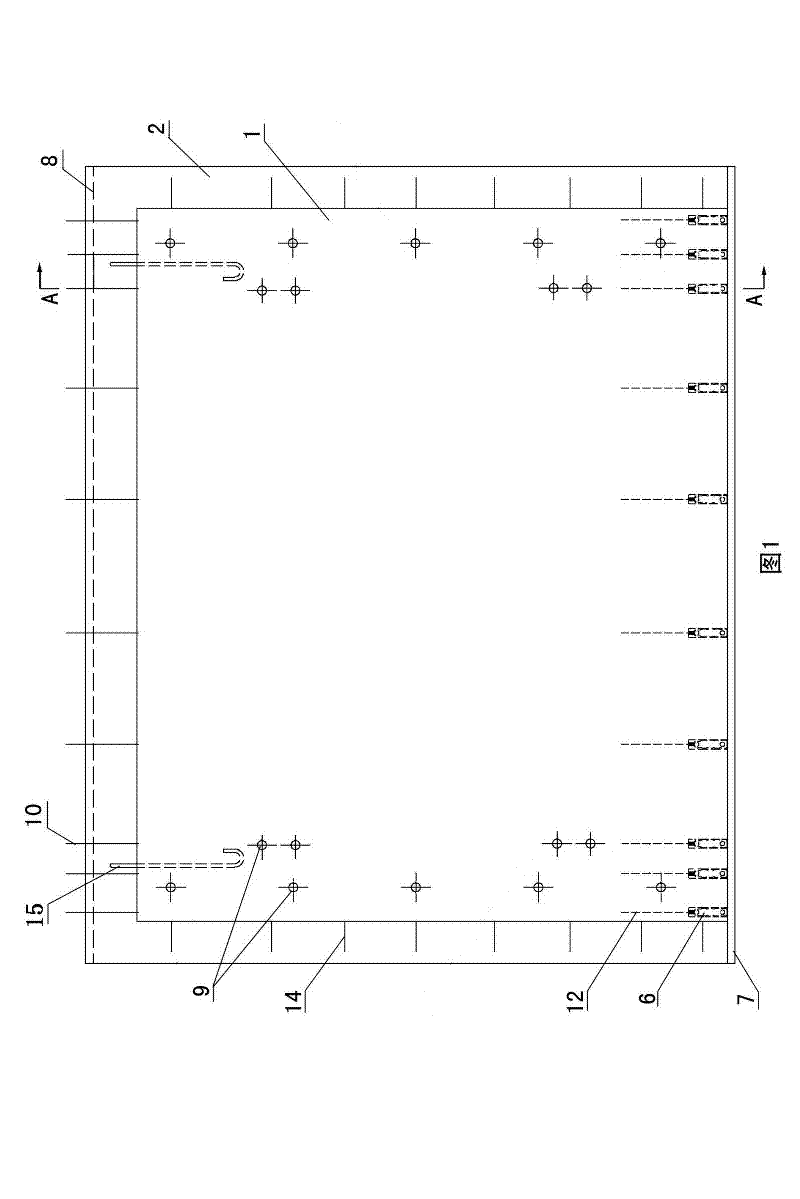

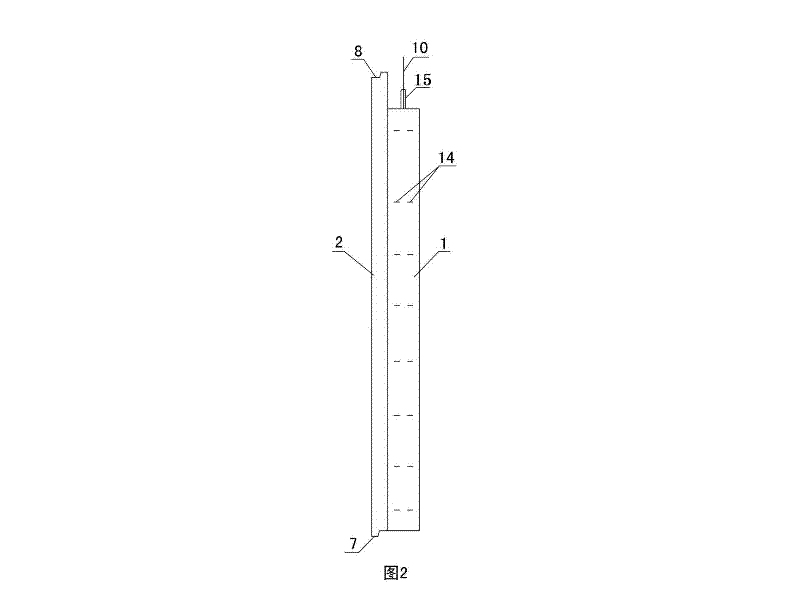

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Precast concrete wallboard and preparation method thereof

ActiveCN101831985ALow costGuarantee the construction qualityConstruction materialForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention relates to a precast concrete wallboard and a preparation method thereof. A wall body has a structural layer and a protection layer from inside to outside, wherein the structural layer is internally provided with a reinforcement cage, and a reinforcement fabric is arranged in the concrete of the protection layer; the protection layer is connected with the structural layer through a transverse connecting reinforcement connected to the reinforcement fabric; the left edge and the right edge of the protection layer protrude out of the structural layer; the lower edge of the protection layer downwards extends out of a protruded port; and the top of the protection layer upwards protrudes out of the structural layer; the upper edge of the protection layer has a dent corresponding to the protruded port of the adjacent precast concrete wallboard on the upper layer; and the two ends of a transverse bar of the reinforcement cage protrudes out of the left side surface and the right side surface of the structural layer of the wall body and form two rows of transverse steel ties bending inwards. The wallboard has the advantages that the construction process is simplified, the construction speed is accelerated, and the construction cost is reduced. Meanwhile, products precast by a factory have uniform specification and quality, and thus, the construction quality of a building structure can be guaranteed sufficiently. The precast concrete wallboard can be widely applied to construction of concrete steel buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

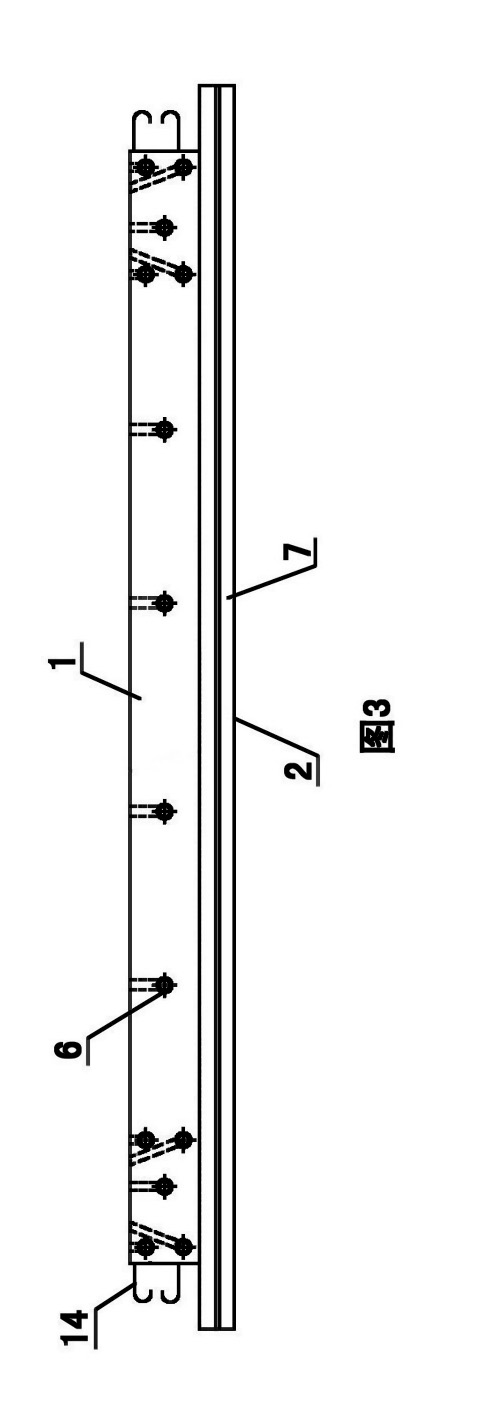

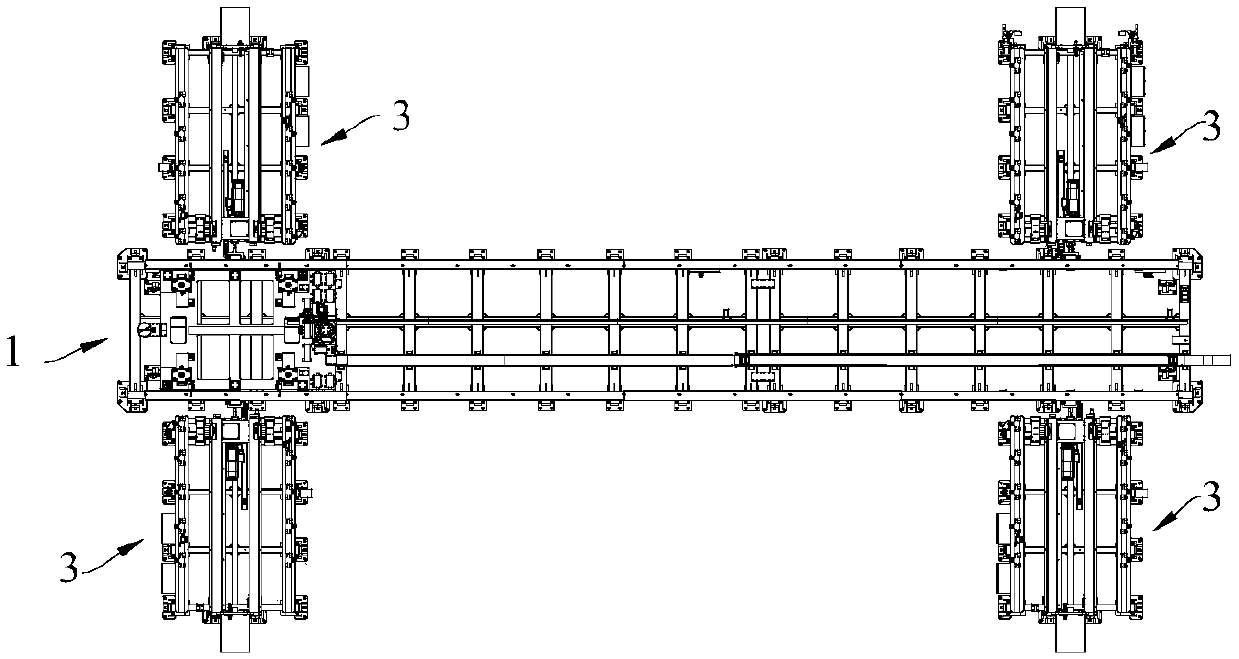

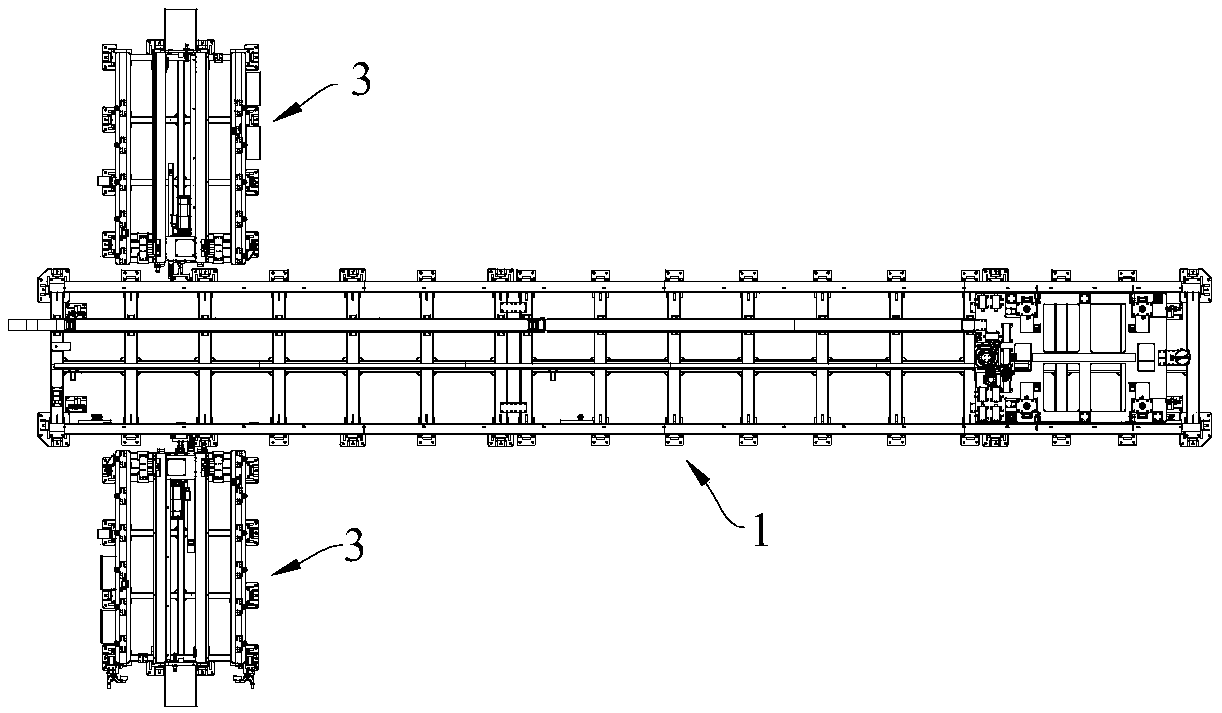

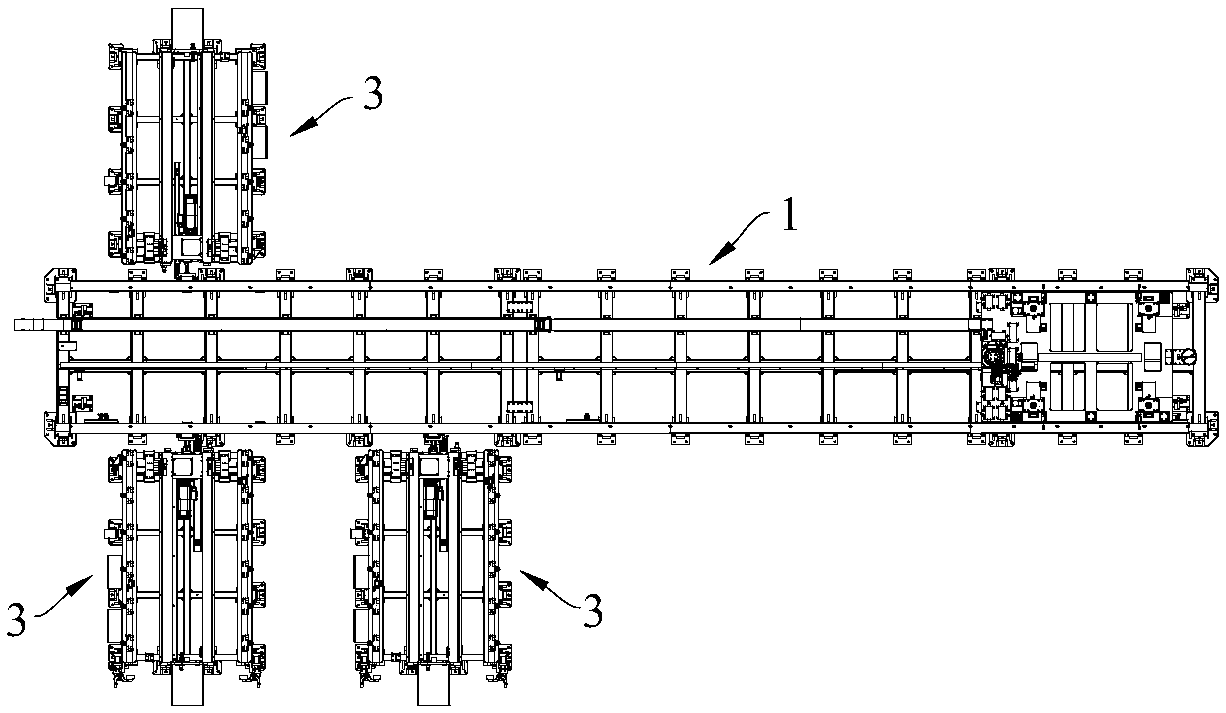

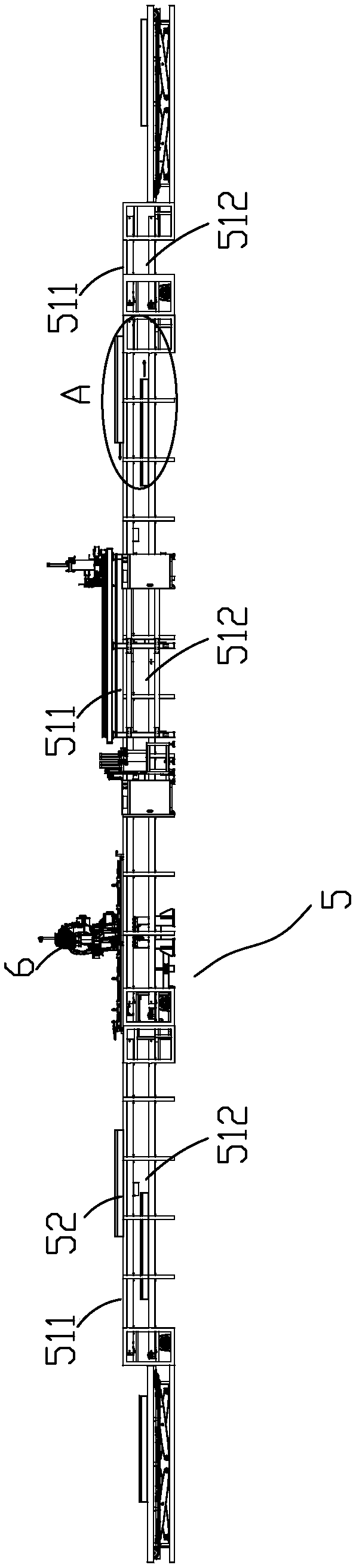

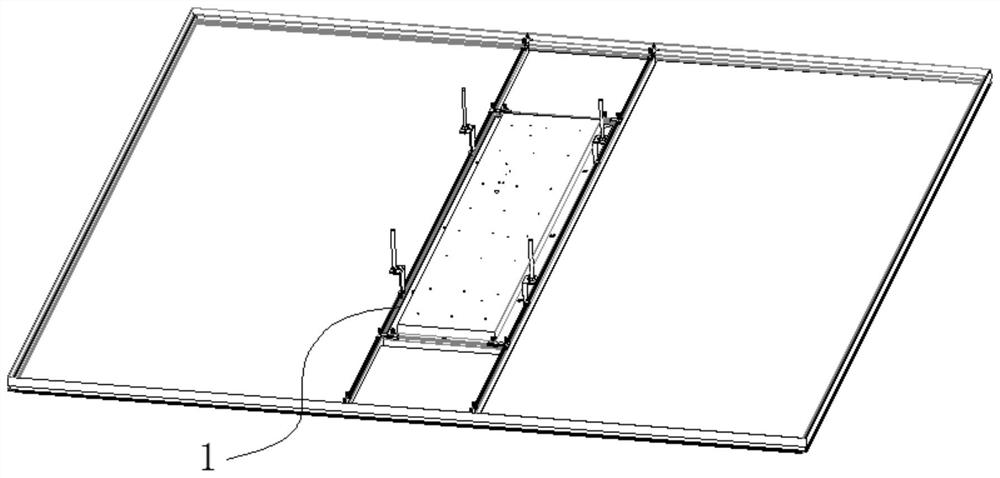

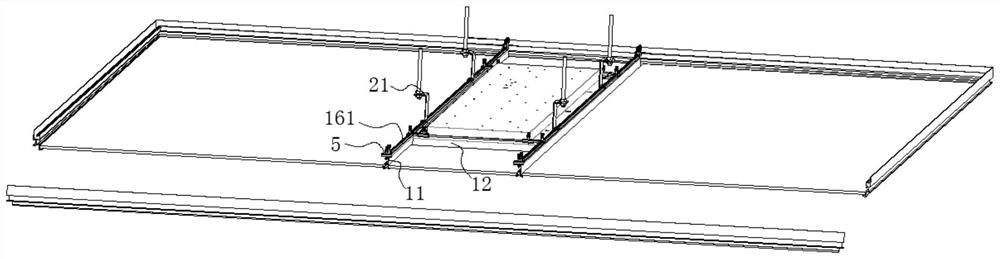

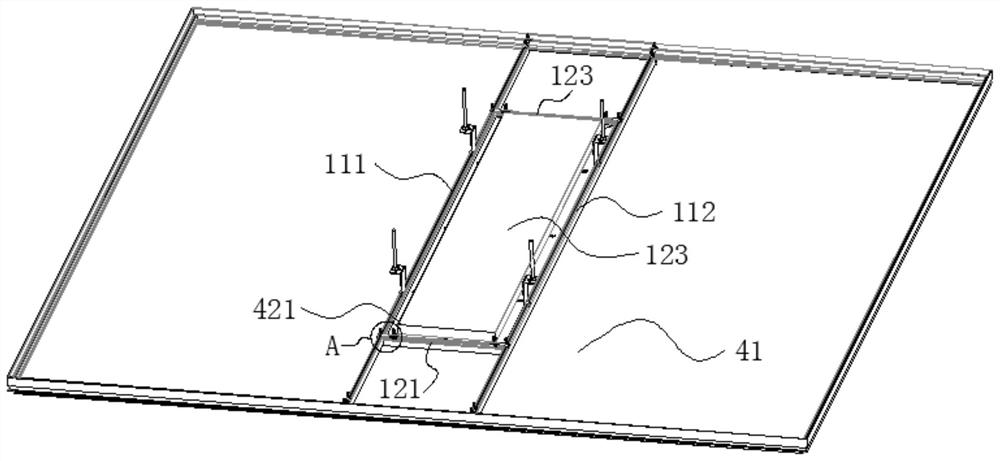

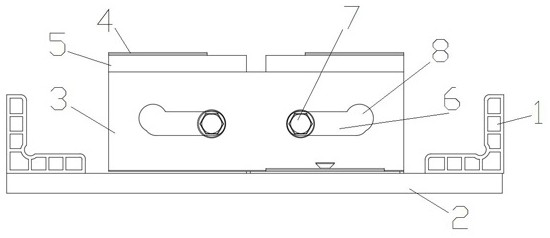

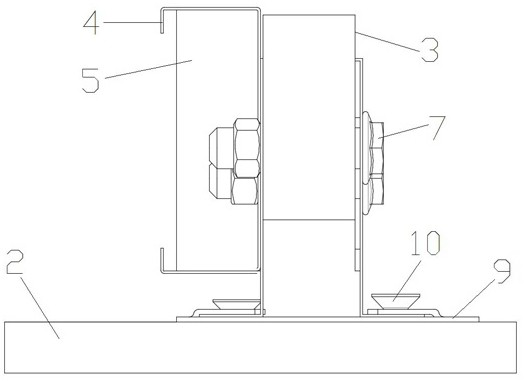

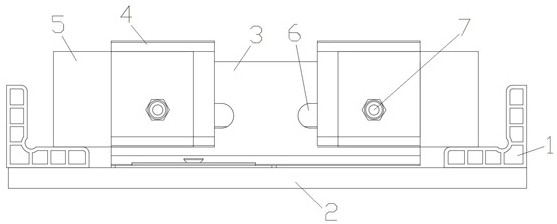

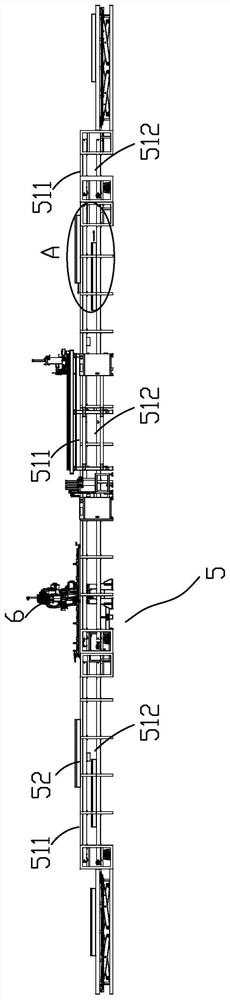

Flexible clamp switching system

ActiveCN109531189AQuick switchSimple mechanical structureWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a flexible clamp switching system. The flexible clamp switching system is used for the clamp switching field. The system comprises a sliding table, a trolley moving mechanism,and multiple clamp warehouses; the sliding table is provided with a first linear guide rail, the trolley moving mechanism can transport clamps along the first linear guide rail, the clamp warehouses are distributed on one side or two sides of the sliding table, and the clamp warehouses can carry clamp switching with the trolley moving mechanism. Each clamp warehouse corresponds to a tool clamp ofone vehicle type, the manner that multiple vehicle types use the independent tool clamps is adopted, the mechanical structure is simplified, and the mounting and maintaining difficulty is reduced; theclamp warehouses are arranged on one side or two sides of the sliding table, the tool clamps of multiple vehicle types can be stored in an online manner, clamp switching is achieved through the sliding table and the trolley moving mechanism, and rapid switching of production of multiple vehicle types can be achieved. According to the system, in the planning stage, a guide-in space of a new vehicle type is reserved, when the new vehicle type is guided in on the later period, only a new clamp warehouse needs to be directly guided in, the transformation construction period is greatly shortened,and the cost is greatly reduced.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Light plastering anhydrite, preparation method and application

The invention belongs to building materials, and particularly relates to light plastering anhydrite which comprises, in 100 parts by weight, 65-80 parts of high-strength anhydrite powder, 4-20 parts of heavy calcium carbonate, 9-20 parts of glass beads, 1-8 parts of methylcellulose, 0.2-5 parts of guar gum mixture and 0.3-4 parts of cassava pregelatinized starch. Raw materials are accurately screened, proportions are scientifically calculated, production technologies are stable and mature, and constructability is strong. The light plastering anhydrite definitely becomes a special green environment-friendly plastering material for novel walls and ceilings in the future, and can be widely applied.

Owner:辽宁飞龙达建材科技有限公司

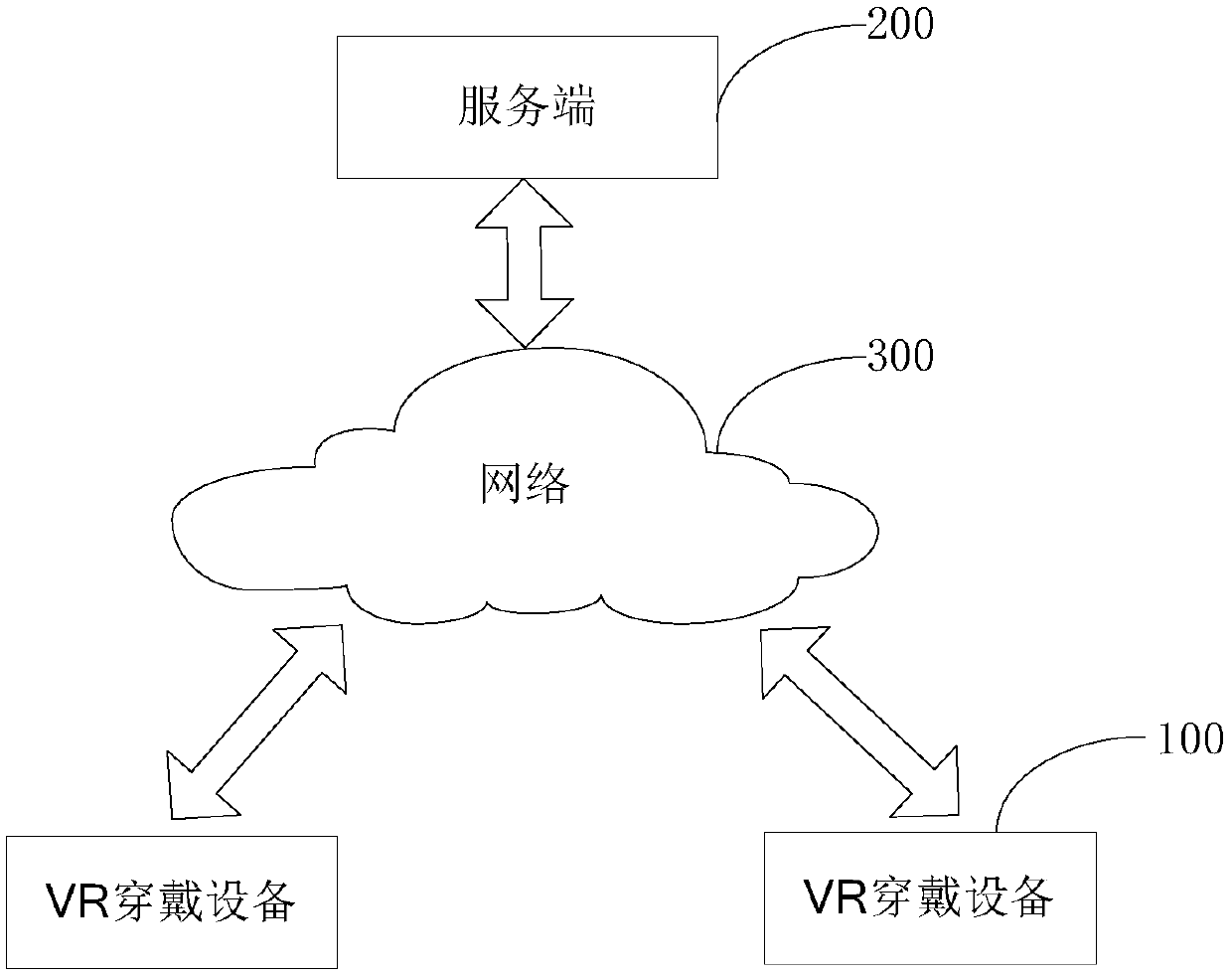

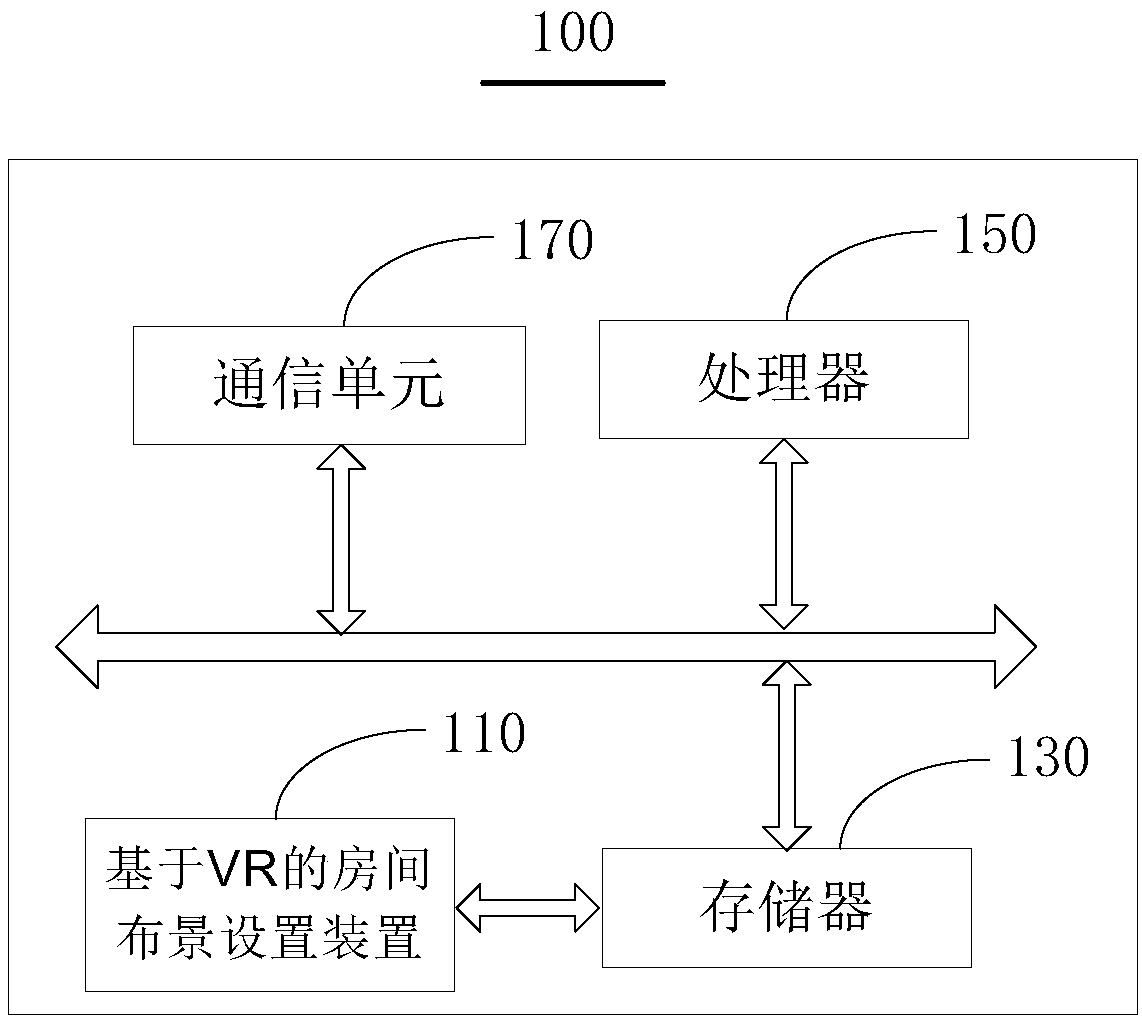

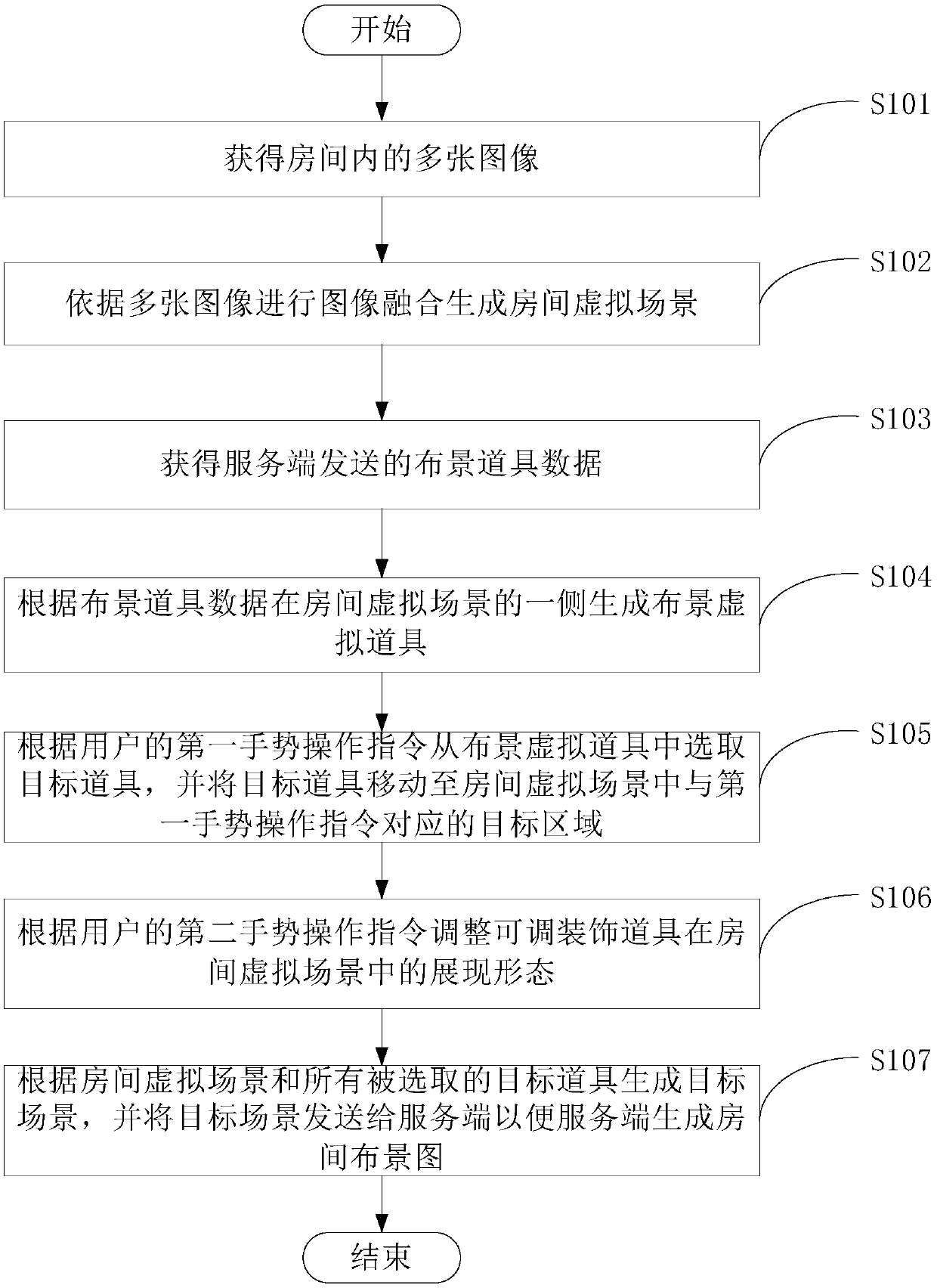

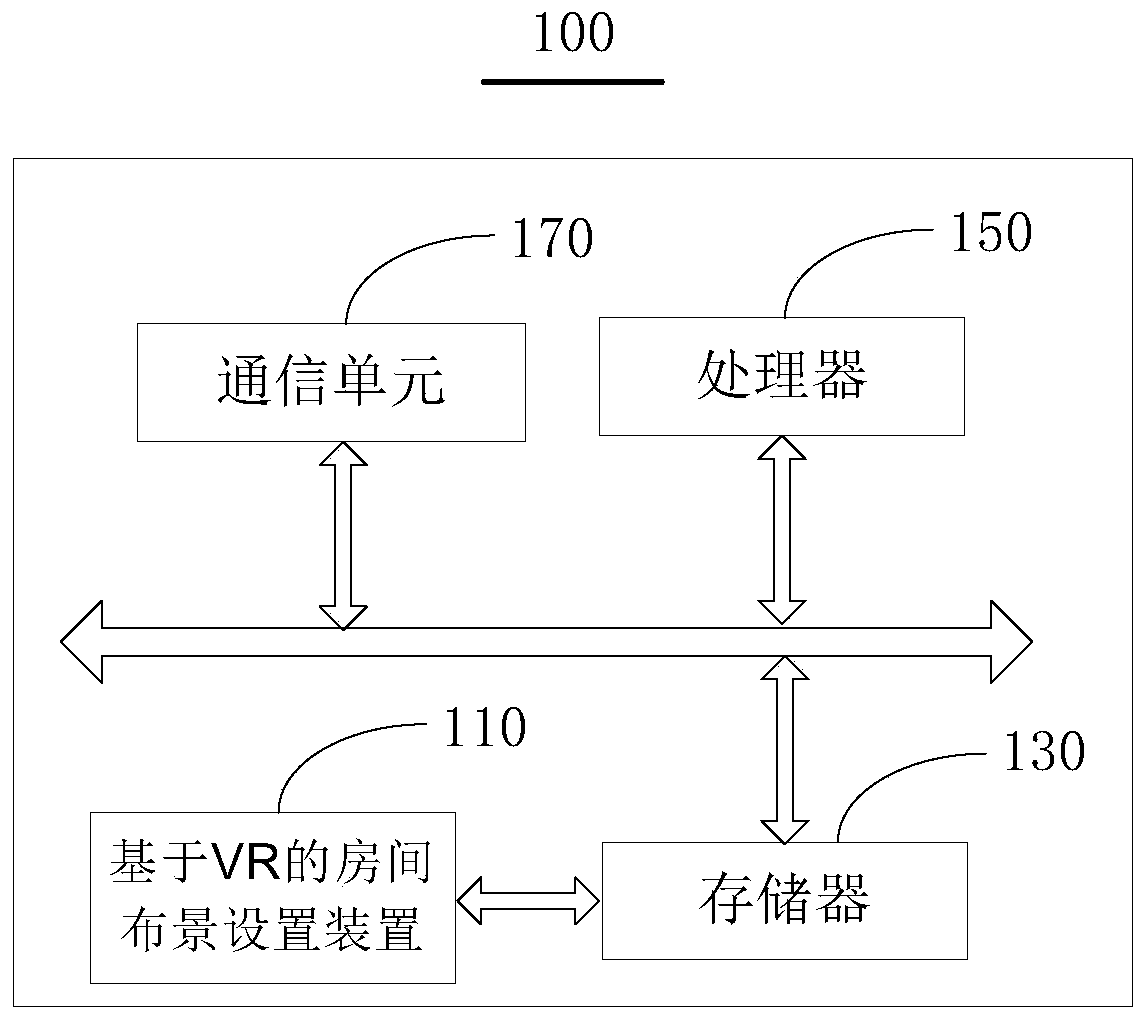

VR-based scenery setting method and device, and VR wearable device

PendingCN109685910AImprove experienceReduce the number of revisions and adjustmentsData processing applicationsImage data processingCognitionVirtual reality

The invention discloses a VR-based room scene setting method and apparatus, and a VR wearable device, and relates to the technical field of virtual reality. The method comprises the following steps: carrying out image fusion according to a plurality of obtained images in a room to generate a room virtual scene; Generating a scene setting virtual prop on one side of the room virtual scene accordingto the scene setting prop data sent by the server; Selecting a target prop according to the first gesture operation instruction, and moving the target prop to a corresponding target area or renderingthe room virtual scene into a color corresponding to the target prop; And generating a target scene according to the room virtual scene and all the selected target props, and sending the target sceneto the server. According to the VR-based room scene setting method and device and the VR wearable equipment, the situation that the decoration effect is far different from the ideal effect of a client due to understanding and cognition deviations in the subsequent decoration process of a decoration company is avoided, the number of times of modification and adjustment is reduced, the decoration period is shortened, and the user experience is improved.

Owner:成都生活家网络科技有限公司

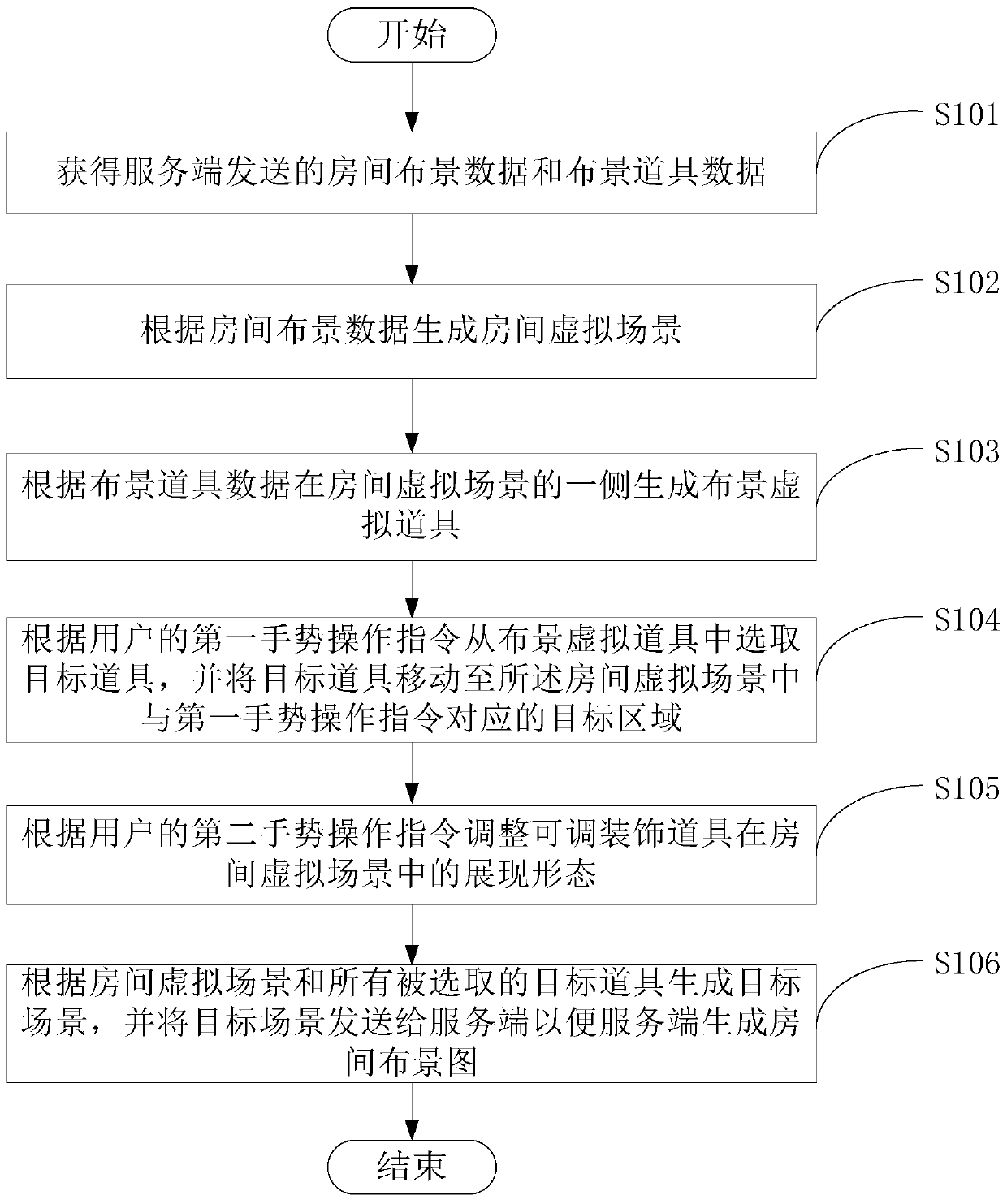

Room scene setting method and device based on VR

PendingCN109741459AImprove experienceAvoid a far cryInput/output for user-computer interactionImage data processingComputer graphics (images)Virtual reality

The invention discloses a room scene setting method and device based on VR, and relates to the technical field of virtual reality. The room scene setting method and device based on VR comprises the steps of obtaining room scene data and scene prop data sent by a server; generating a room virtual scene according to the room scene data; generating a setting virtual prop according to the setting propdata; selecting a target prop from the scene setting virtual props according to the first gesture operation instruction, and moving the target prop to a target area corresponding to the first gestureoperation instruction in the room virtual scene or rendering the room virtual scene into a color corresponding to the target prop; and generating a target scene, and sending the target scene to the server. According to the room scene setting method and device based on VR, the situation that the decoration effect is far different from the ideal effect of a client due to understanding and cognitiondeviations of a decoration company in the subsequent decoration process can be avoided, the number of times of modification and adjustment is reduced, the decoration period is shortened, and the userexperience is improved.

Owner:成都生活家网络科技有限公司

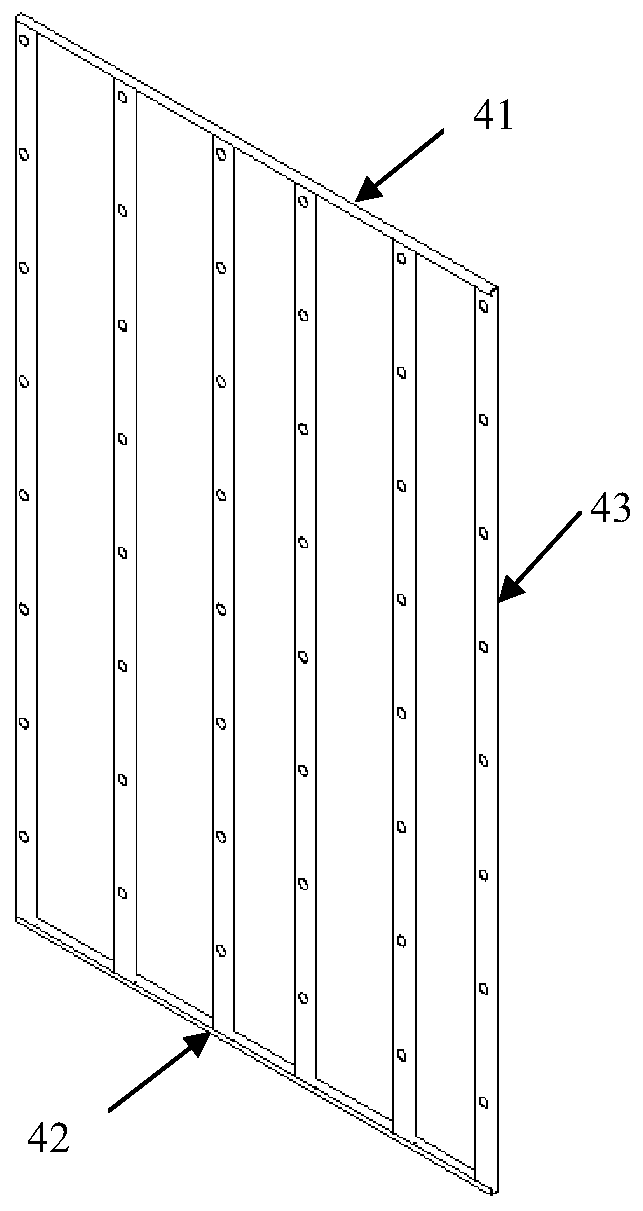

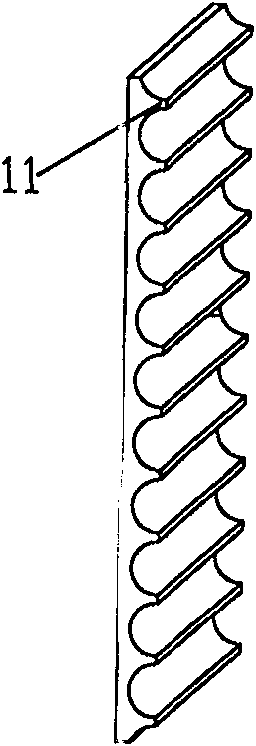

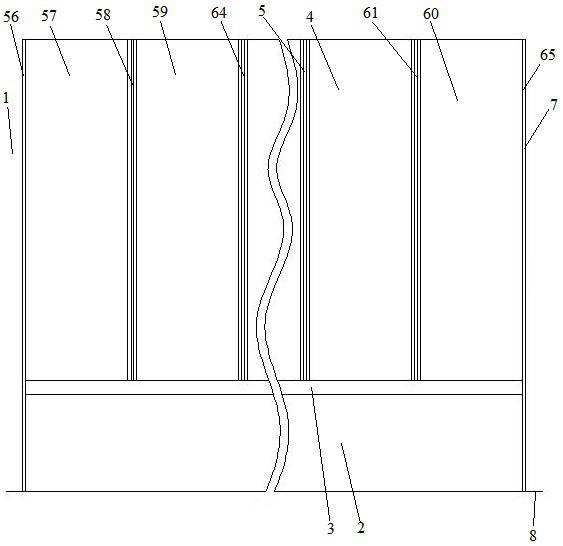

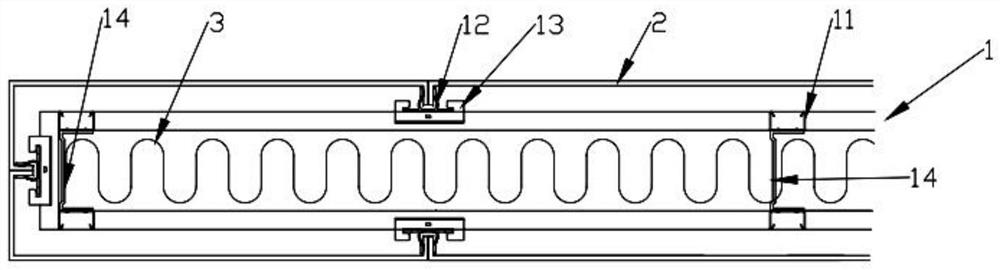

Modular nuclear magnetic shielding body

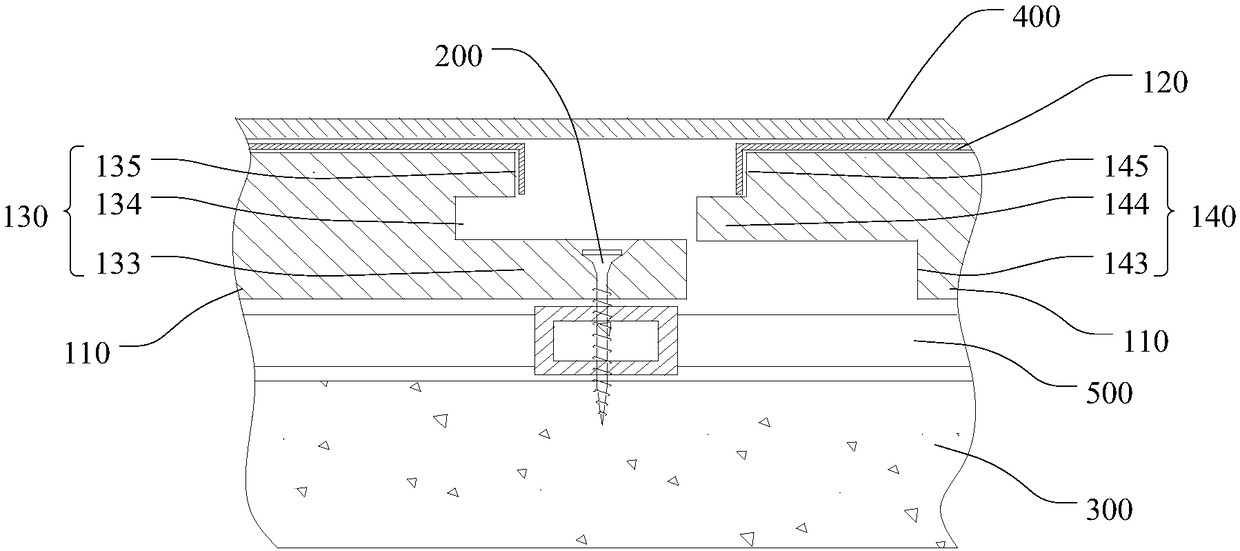

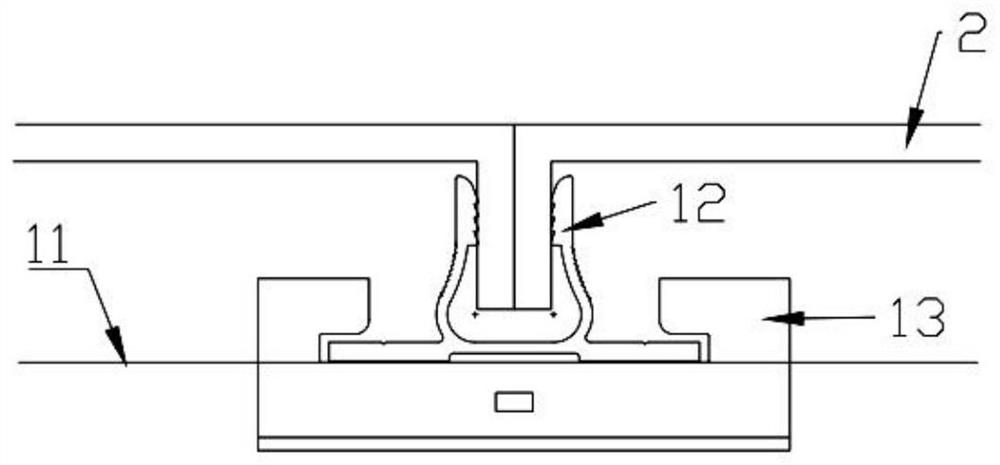

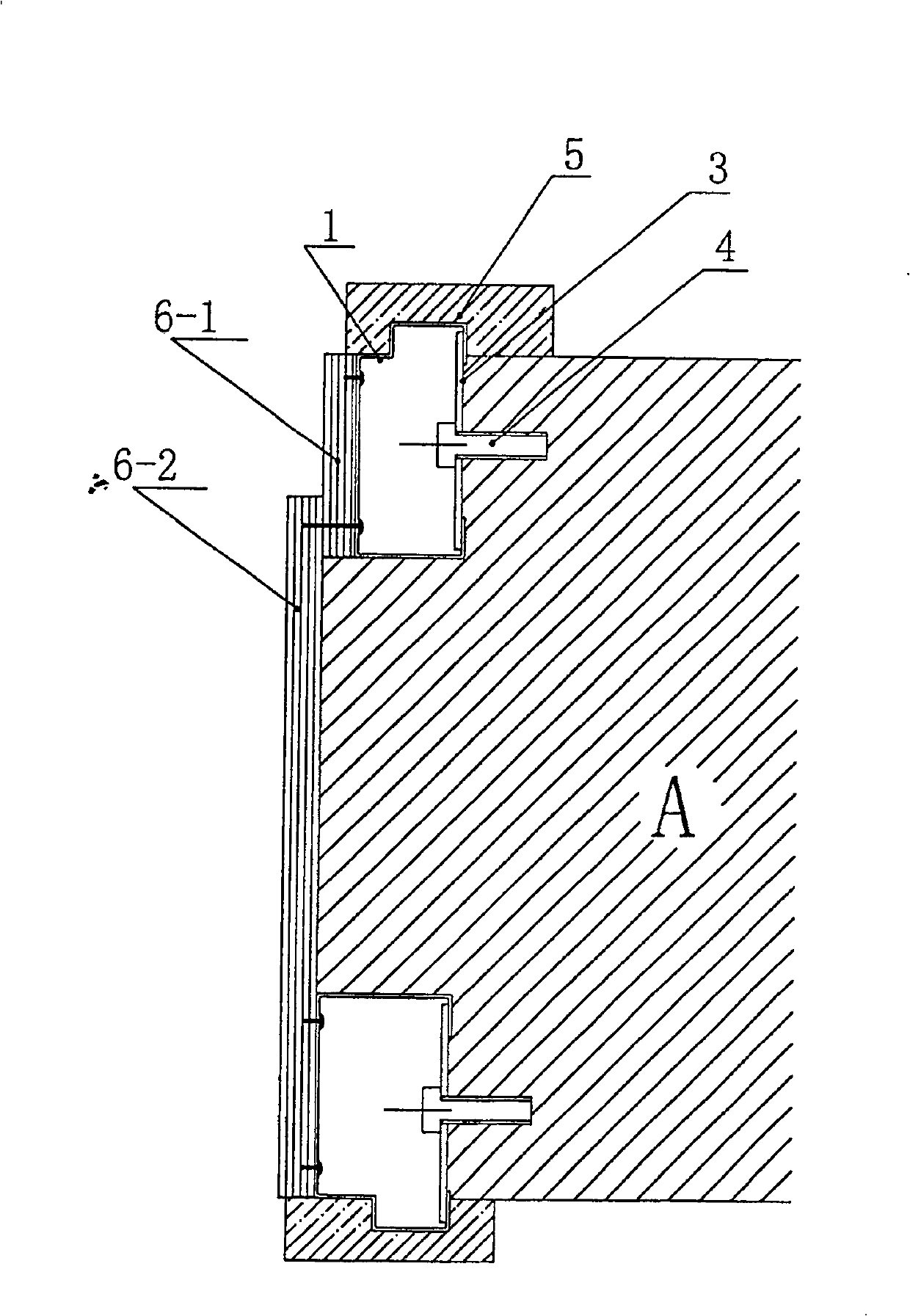

PendingCN108442741AThe installation process is simple and convenientShorten the renovation periodCovering/liningsSmall buildingsEngineeringElectrical and Electronics engineering

The invention discloses a modular nuclear magnetic shielding body. The modular nuclear magnetic shielding body comprises a plurality of shielding plates and connecting pieces, wherein the shielding plates are arranged in an array mode, and the shielding plates are connected with a wall body through the connecting pieces. The shielding plates are of rectangular structures, and male grooves and female grooves are separately formed in the two sides, opposite to each other, of the shielding plates. Every two adjacent shielding plates are connected with each other in a clamped mode through cooperation of the male grooves and the female grooves. The connecting pieces penetrate through the female grooves, so that the shielding plates are connected with the wall body. The shield plates comprise density plate layers and red copper skin layers. The surfaces, away from the wall body, of the density plate layers are coated with the red copper skin layers, and the surrounding surfaces, perpendicular to the wall body, of the density plate layers are covered with the red copper skin layers. According to the modular nuclear magnetic shielding body, the shielding plates are connected with each another through the male grooves and female grooves, and the red copper skin layers of every two adjacent shielding plates extend to the side portions of the shielding plates and are fixed under the mutual extrusion of the two shielding plates. Therefore, according to the modular nuclear magnetic shielding body, the red copper skin layers are not required to be welded, the installation process of themodular nuclear magnetic shielding body is simple, the decoration construction period is short.

Owner:深圳市泛亚环境工程开发设计股份有限公司

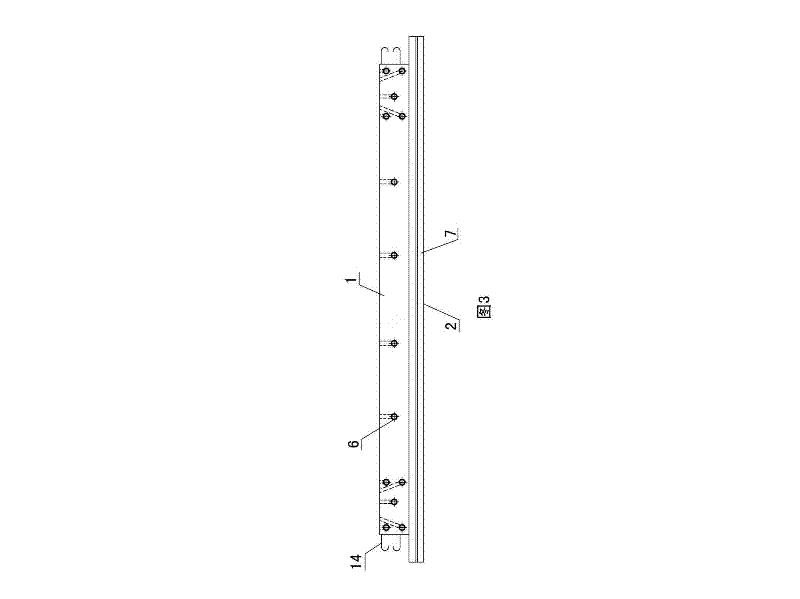

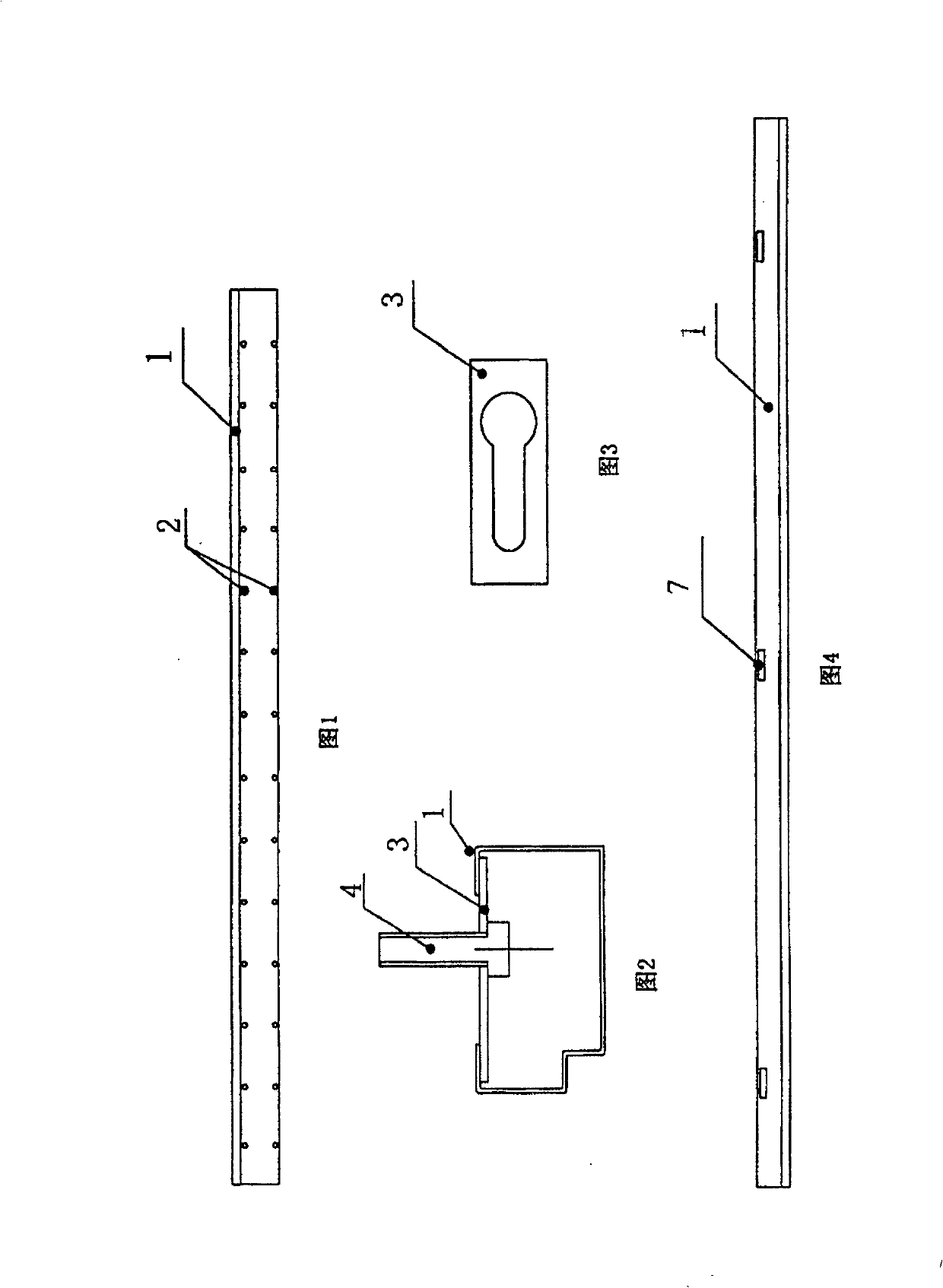

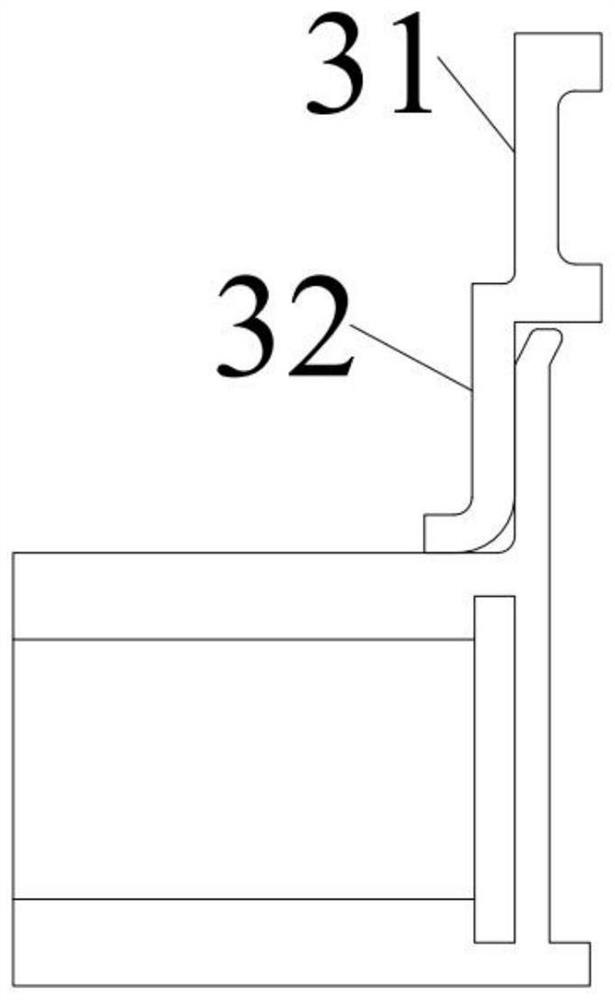

Door window trim capable of being intercepted and used randomly

InactiveCN101161974AIncrease productivityImprove installation efficiencyWindow/door framesEngineeringMechanical engineering

The invention discloses a door and window profile which can be cut and used freely comprising a cleading; the cleading is provided with an inner cavity and / or an element rest. The invention is characterized in that the inner cavity and / or an element rest extend horizontally along the cleading. The cleading of the door and window profile can undergo standardized production with site cut and installation, thereby improving working efficiency and shortening decoration period.

Owner:程礼中

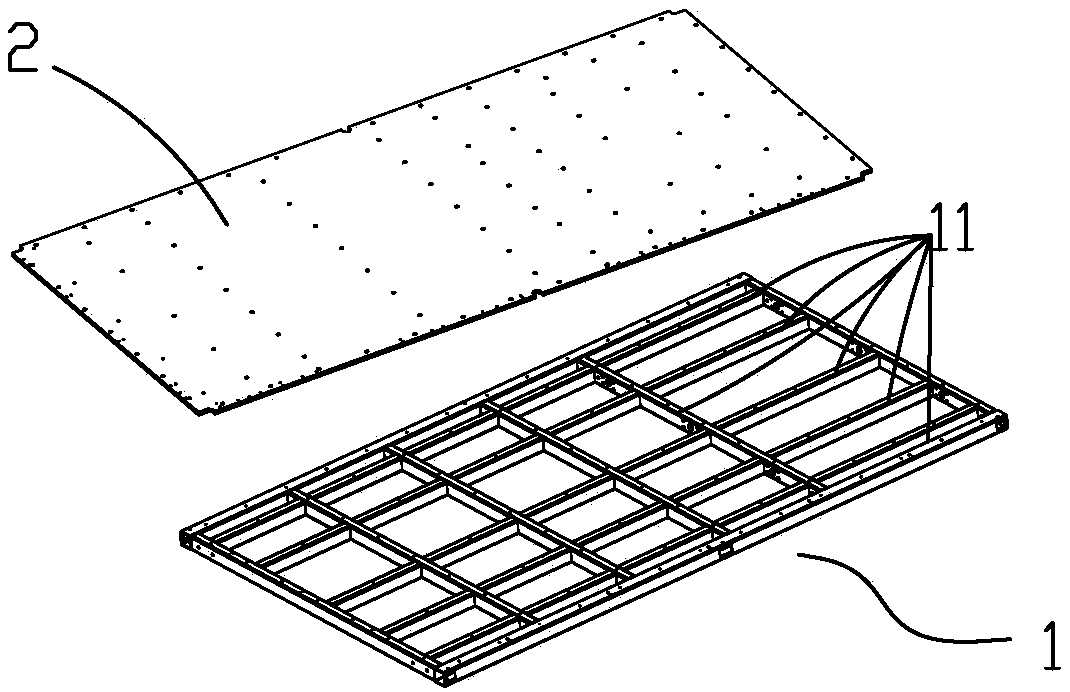

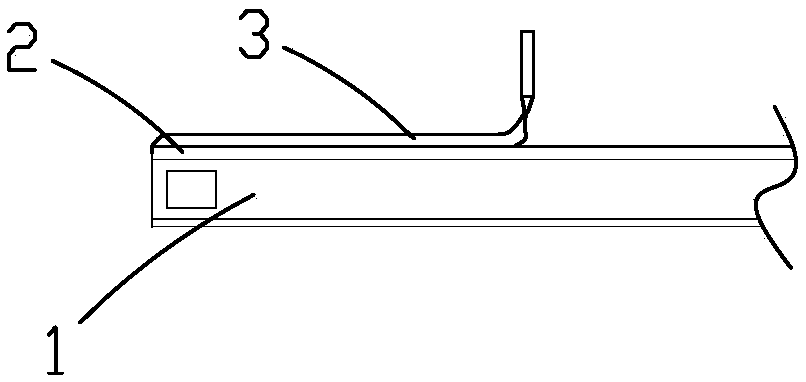

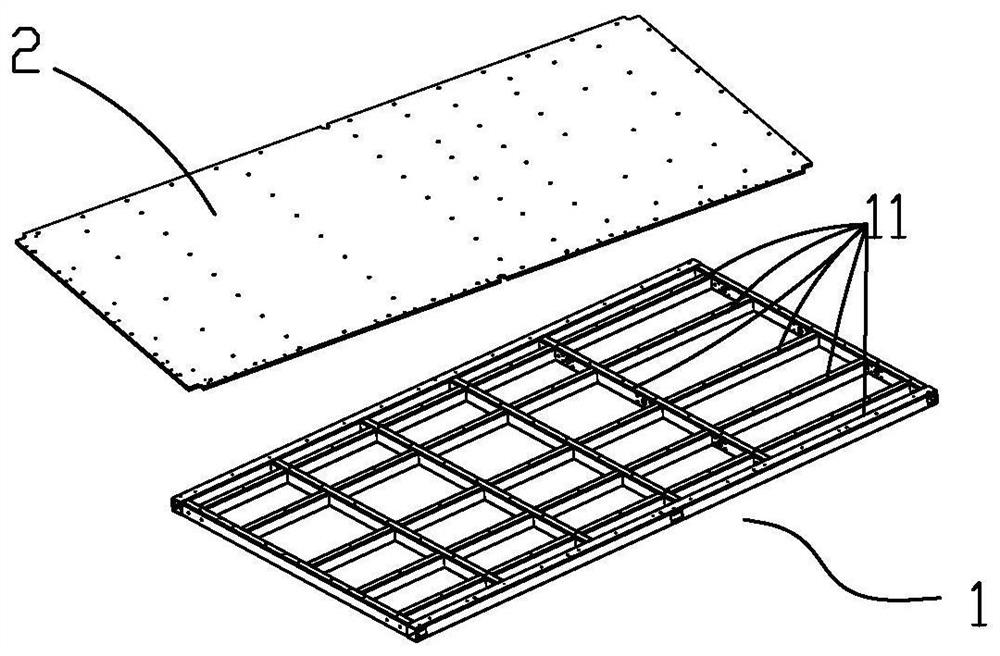

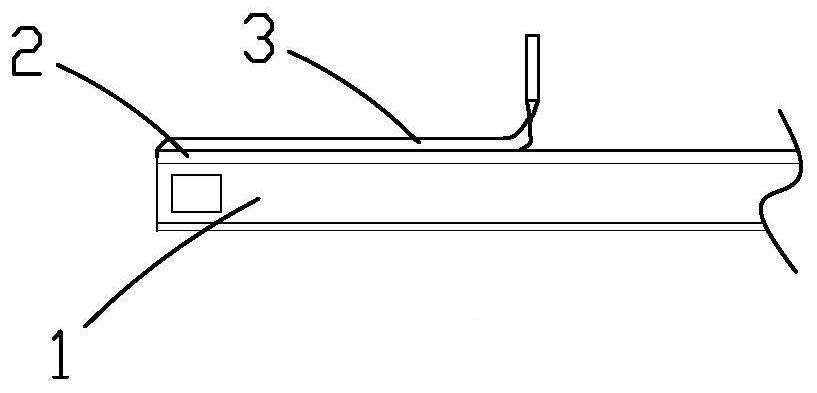

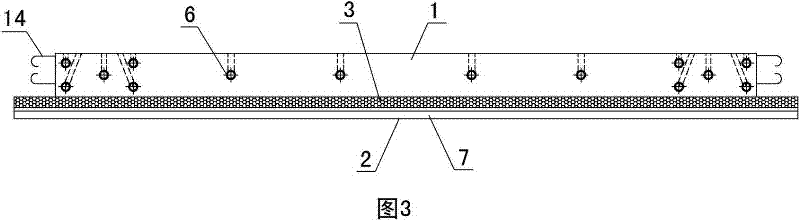

Wallboard manufacturing process

The invention discloses a wallboard manufacturing process. The wallboard manufacturing process is characterized by comprising the steps that A, a keel component (1) is manufactured; B, a bottom plate(2) is fixed to one side of the keel component (1); C, adhesive glue is applied on the bottom plate (2); and D, a plurality of tiles (4) are pasted onto the bottom plate (2). The tiles are pasted on the wallboard manufactured by the wallboard manufacturing process in a workshop, when a house is decorated, only a plurality of wallboard modules are transported to a construction site, the wallboard is fixed and installed to the building wall body, cutting and pasting tiles at the construction site are avoided, the efficiency is improved, the waste of the material is avoided, and the cost is reduced.

Owner:ZHONGSHAN SALLY SHOWER EQUIP

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527BGuarantee the construction qualityLow costWallsBuilding material handlingReinforced concretePolystyrene

Owner:华筑(辽宁)建筑工程设计有限公司

Precast composite outer insulated wall plate and manufacturing method thereof

ActiveCN101831986BGuarantee the construction qualityLow costConstruction materialBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a precast composite outer insulated wall plate and a manufacturing method thereof. The plate body of the precast composite outer insulated wall plate is sequentially provided with a structural layer, an insulated layer and a protective layer from inside to outside, wherein a reinforcing cage is arranged in the structural layer; a reinforcing mesh is arranged in the concrete of the protective layer; the structural layer, the insulated layer and the protective layer are alternately anchored together through connecting pieces which are in point distribution; the left edges and the right edges of the protective layer and the insulated layer protrude out of the structural layer; a convex opening downwards extends from the lower edge of the protective layer; the tops ofthe protective layer and the insulated layer upwards protrude out of the structural layer; and the upper edge of the protective layer is provided with a concave opening corresponding to the convex opening of the adjacent precast composite outer insulated wall plate at the upper layer. The wall plate simplifies the construction processes, accelerates the construction speed and reduces the engineering cost. Moreover, products precast in factories have consistent specification and uniform quality, the construction quality of the building structure can be fully ensured, industrialization, standardization and generalization of building walls are realized, and the invention can be widely applied to construction of reinforced concrete buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Method for covering wall brick surface with sticking wall bricks

The invention discloses a method for covering the wall brick surface with sticking wall bricks. The method comprises the following four steps of original wall surface treatment, adhesive preparation, seam filling and wall brick sticking. The adhesive is prepared from the following raw materials of, by weight, 10-15 parts of gypsum powder, 4-6 parts of wheat starch, 2-4 parts of colza oil, 18-22 parts of polyving akohol, 6-12 parts of sodium stearate, 14-18 parts of white emulsion, 3-5 parts of sodium hexametaphosphate and 8-12 parts of polyoxyethylene. According to the method for covering the wall brick surface with the sticking wall bricks, the wall bricks can be firmly stuck onto the original wall surface, and the conditions of wall brick cracking, tilting and falling off do not occur. The method greatly simplifies the sticking procedures of the wall bricks in the secondary decorating process, the decorating construction period is shortened, noise generated in the wall brick sticking process is small, and the decorating waste is also very little.

Owner:广东质鼎装饰工程有限公司

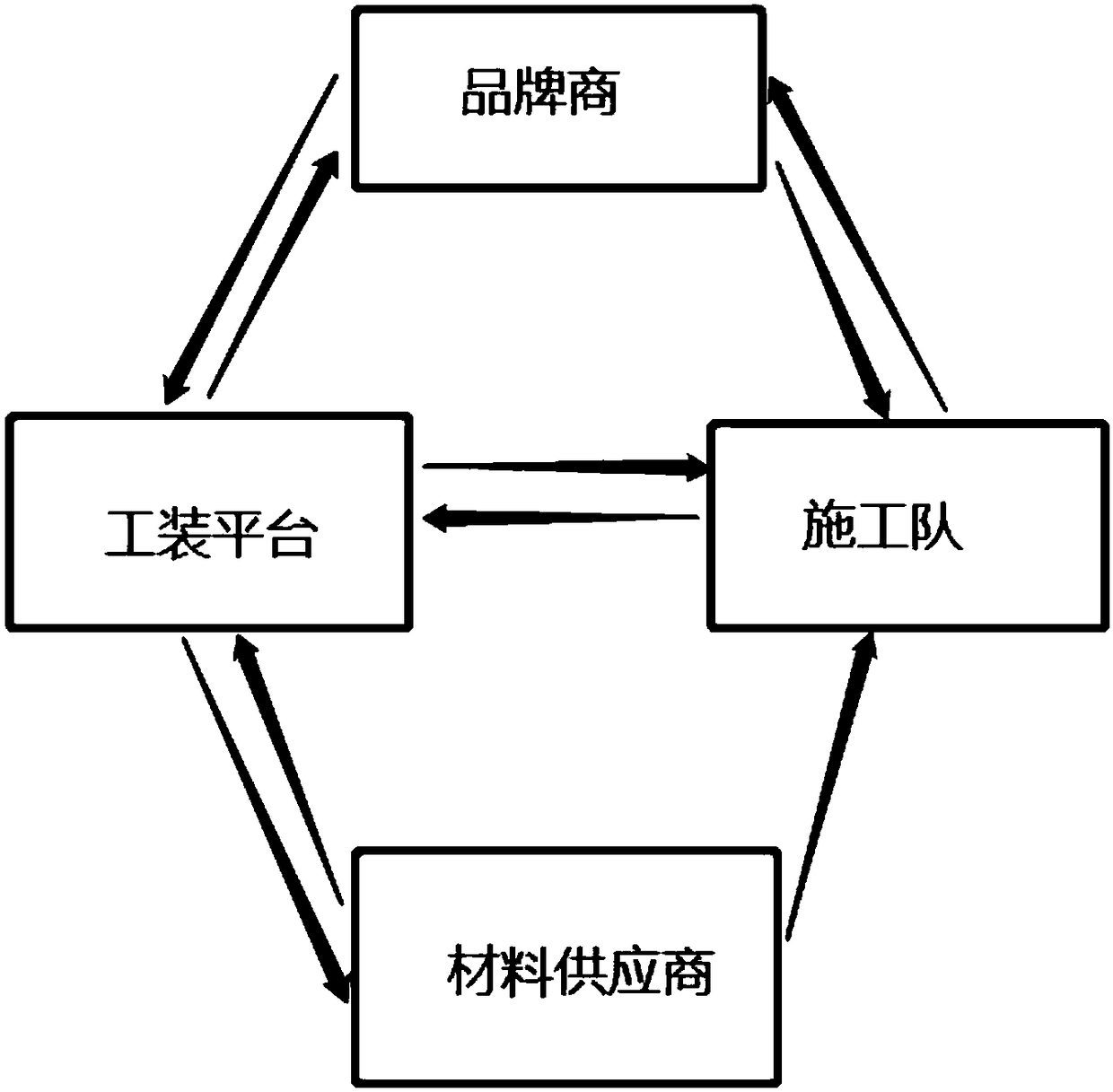

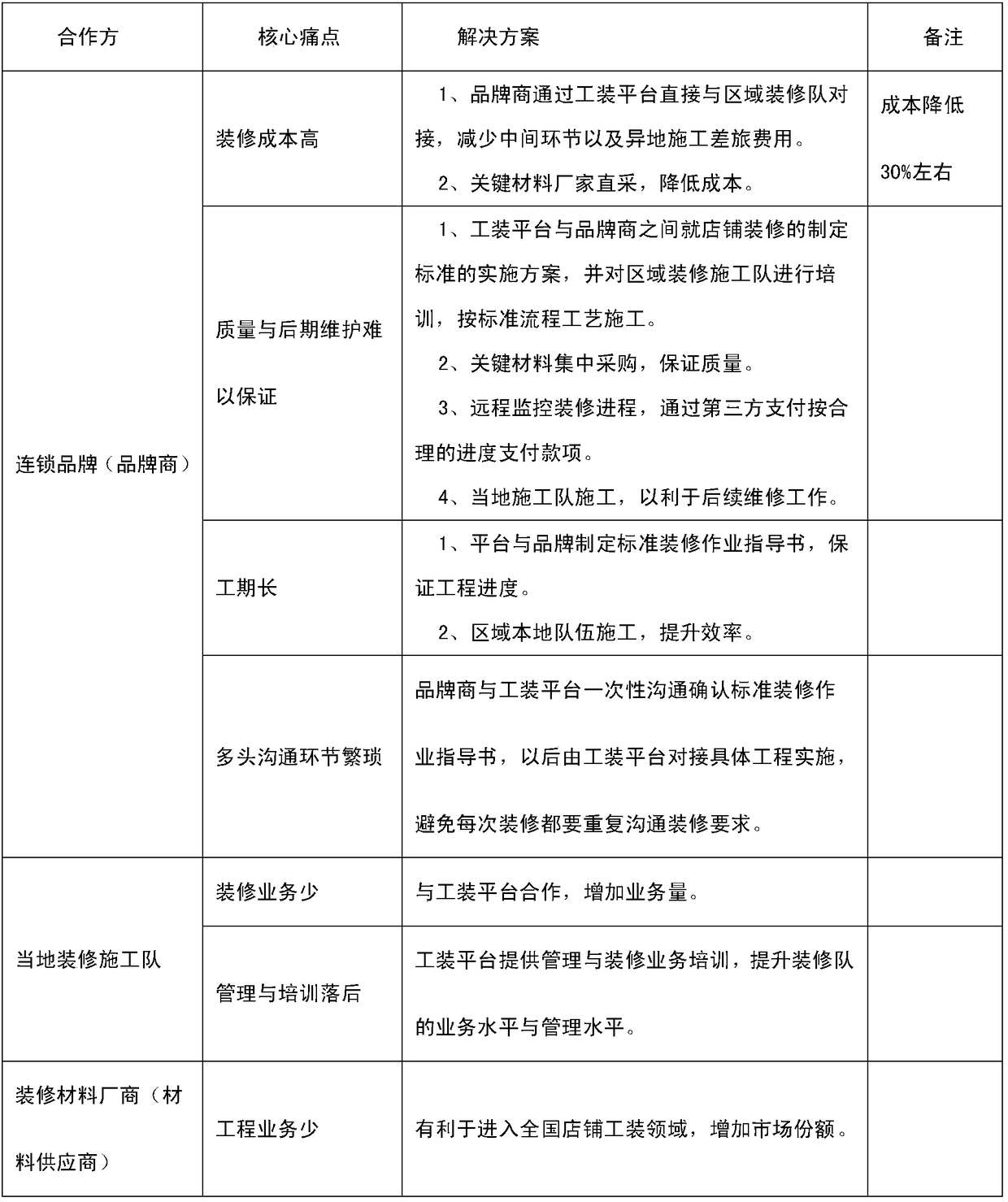

A shop tooling Internet platform business model

InactiveCN109242635AEnsure project qualityGuarantee the durationOffice automationBuying/selling/leasing transactionsThe InternetBusiness pattern

The invention discloses a shop tooling Internet platform business model, which comprises a tooling platform, a brand owner, a material supplier and a decoration construction team. The tooling platformcomprises an on-line operation organization and an off-line service organization established in various parts of the country, wherein the on-line operation organization establishes bi-directional on-line cooperation for the brand owner, material supplier and decoration construction teams, and the off-line service organization establishes bi-directional off-line cooperation for the brand owner, material supplier and decoration construction team; The brand owner and the material supplier are communicatively connected with the tooling platform through the Internet; The decoration construction team communicates with the tooling platform through the Internet and jointly completes the tooling engineering of the brand merchant. The shop tooling Internet platform is constructed, the invention provides service for the chain brand national shops, the national regional decoration teams and the main decoration material manufacturers, thereby ensuring the decoration quality, facilitating the maintenance in the later period and reducing the decoration cost.

Owner:开店宝(广州)装饰工程有限公司

Precast composite wallboard with door/window holes and manufacturing method thereof

ActiveCN101818541BGuarantee the construction qualityLow costWallsReinforced concreteArchitectural engineering

The invention discloses a precast composite wallboard with door / window holes and a manufacturing method thereof. The body of the precast composite wallboard is provided with door / window holes thereon and is also sequentially provided, from inside to outside, with a structural layer, a heat preservation layer and a protective layer, wherein the structural layer is internally provided with a reinforcing cage, concrete of the protective layer is internally provided with a reinforcing mesh, the structural layer, the heat preservation layer and the protective layer are anchored with each other in a penetrative manner via connectors which are distributed in a spotted manner, the left and right edges of the protective layer and the heat preservation layer protrude to the structural layer, the lower edge of the protective layer extends downwards out of a convex opening, the top parts of the protective layer and the heat preservation layer protrudes upwards to the structural layer, and the upper edge of the protective layer is provided with a concave opening corresponding to the convex opening of the adjacent precast composite wallboard at the upper layer. The wallboard has the advantages of simplifying construction procedures, speeding up construction speed and reducing project cost. In addition, the products precast in factory are consistent in specification and quality, the construction quality of building structure can be fully guaranteed, and the wallboard can be extensively applied to the construction of reinforced concrete buildings in the construction industry.

Owner:雄安万科绿色研发有限公司

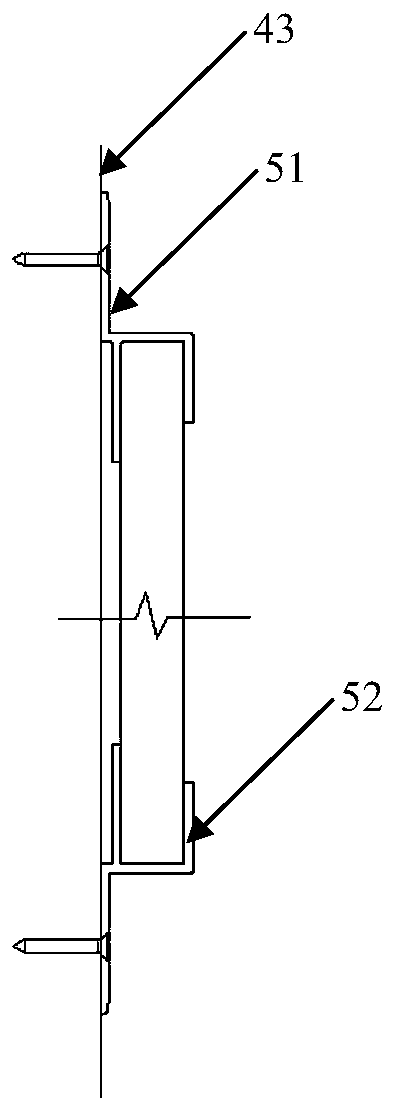

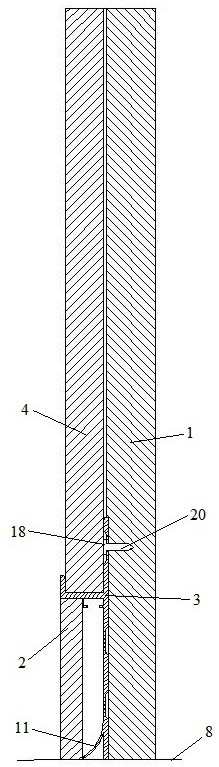

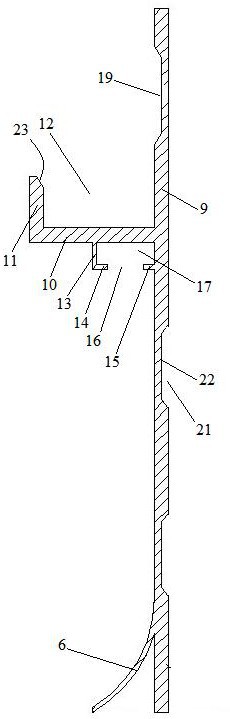

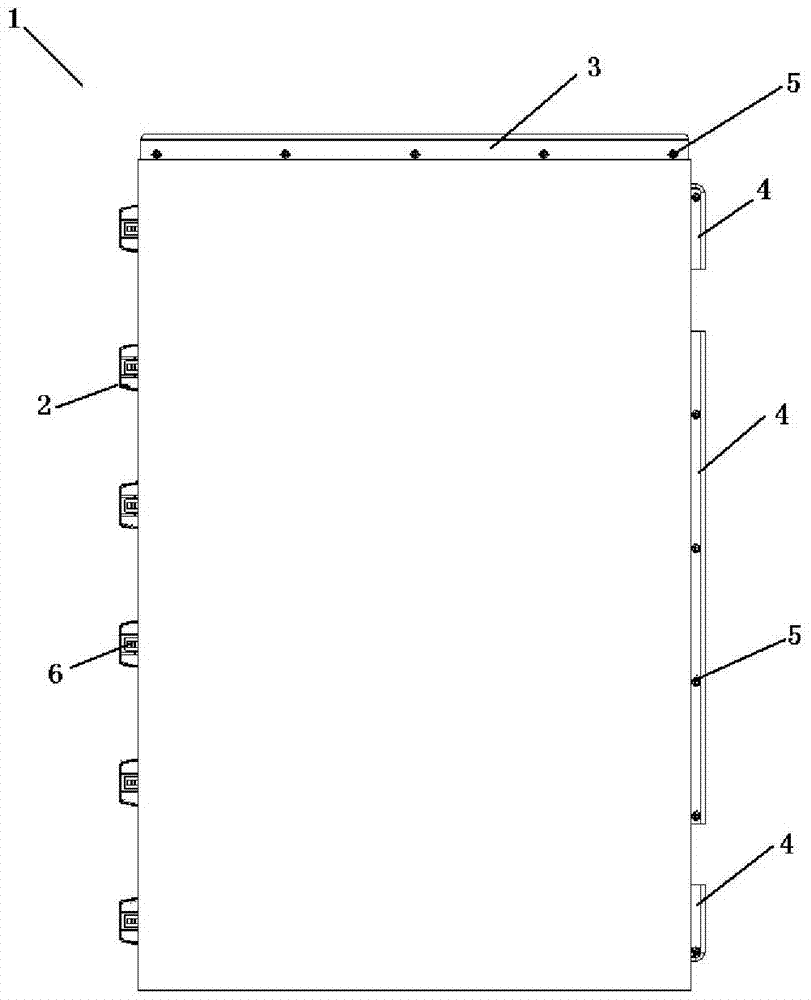

Quick door pocket installation system

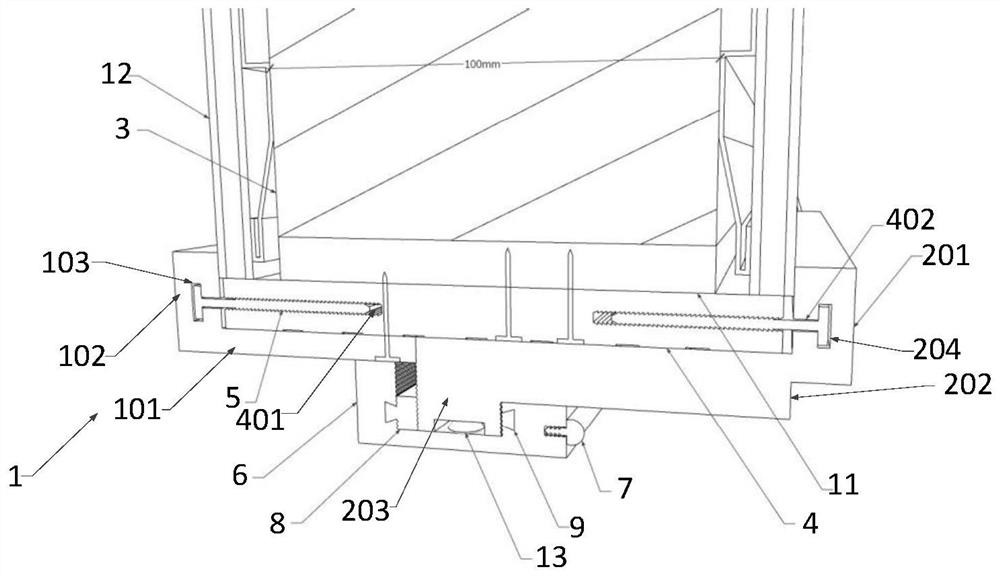

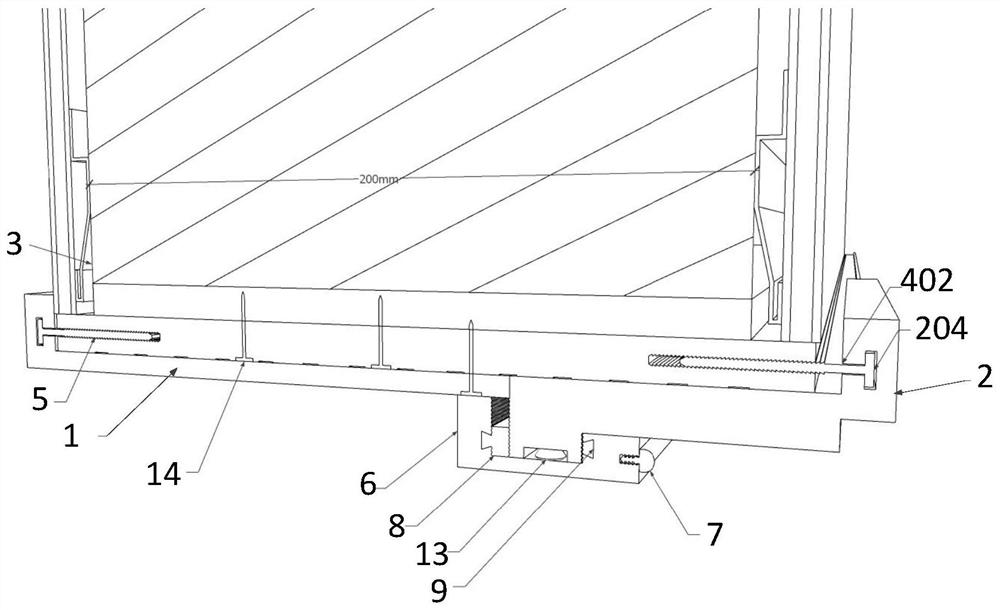

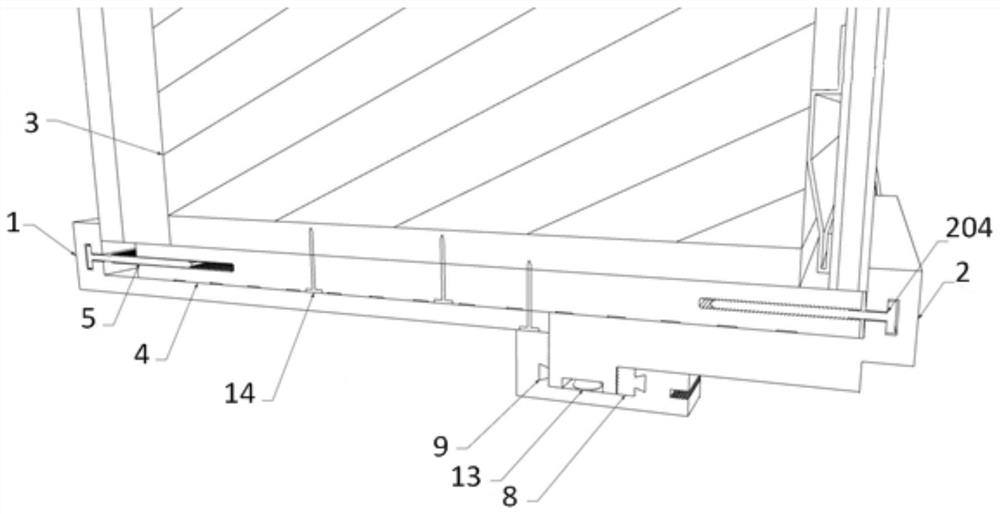

InactiveCN111809835AWrap implementationRealize forceBuilding constructionsStructural engineeringMechanical engineering

The invention provides a quick door pocket installation system. The quick door pocket installation system can be subjected to mass production and can adapt to different situations through overall cooperation to form a door pocket after installation. The quick door pocket installation system comprises a first mounting plate, a second mounting plate, lining plates, a door stop strip and a door stopcushion pad, wherein the first mounting plate and the second mounting plate are oppositely arranged on two sides of a wall; the lining plates are arranged between the first mounting plate and the walland between the second mounting plate and the wall respectively and are connected to the first mounting plate and the second mounting plate through plug-in pieces separately; the door stop strip abuts against the first mounting plate and the second mounting plate, and one end of the second mounting plate is placed in the door stop strip; and the door stop cushion pad is arranged on one side of the door stop strip. The quick door pocket installation system can meet the on-site requirements after being cut according to the on-site size, the cost is reduced while the construction efficiency is shortened, and the decoration period is further shortened.

Owner:变形积木(北京)科技有限公司

Ceramic tile dry hanging system and installing method thereof

PendingCN110805221AShorten the setting timeShorten the timeCovering/liningsMechanical engineeringIndustrial engineering

The invention discloses a ceramic tile dry hanging system and an installing method thereof. The ceramic tile dry hanging system comprises an external corner assembly and a leveling keel module. The external corner assembly comprises an external corner clamping piece, and the external corner clamping piece comprises a first right-angled plate, a second right-angled plate, a first clamping groove and a second clamping groove. The first right-angled plate is perpendicularly connected with the second right-angled plate. The first clamping groove comprises a first groove bottom plate, a first groove side wall plate and a second groove side wall plate, the first right-angled plate and the first groove bottom plate are connected, and the first groove side wall plate and the second groove side wall plate both extend in the direction away from the second right-angled plate. The second clamping groove comprises a second groove bottom plate, a third groove side wall plate and a fourth groove sidewall plate, and the second right-angled plate is connected with the second groove bottom plate. The leveling keel module is provided with a first installing face and a second installing face which are perpendicular, the second groove side wall plate is installed on the first installing face, and the fourth groove side wall plate is installed on the second installing face. By adopting the ceramictile dry hanging system, the installing space can be saved, the installing efficiency can be improved, and the labor cost is saved.

Owner:ZHEJIANG YASHA DECORATION

A method for covering and pasting wall bricks on the surface of wall bricks

The invention discloses a method for covering the wall brick surface with sticking wall bricks. The method comprises the following four steps of original wall surface treatment, adhesive preparation, seam filling and wall brick sticking. The adhesive is prepared from the following raw materials of, by weight, 10-15 parts of gypsum powder, 4-6 parts of wheat starch, 2-4 parts of colza oil, 18-22 parts of polyving akohol, 6-12 parts of sodium stearate, 14-18 parts of white emulsion, 3-5 parts of sodium hexametaphosphate and 8-12 parts of polyoxyethylene. According to the method for covering the wall brick surface with the sticking wall bricks, the wall bricks can be firmly stuck onto the original wall surface, and the conditions of wall brick cracking, tilting and falling off do not occur. The method greatly simplifies the sticking procedures of the wall bricks in the secondary decorating process, the decorating construction period is shortened, noise generated in the wall brick sticking process is small, and the decorating waste is also very little.

Owner:广东质鼎装饰工程有限公司

Door window trim capable of being intercepted and used randomly

InactiveCN100577981CIncrease productivityImprove installation efficiencyWindow/door framesEngineeringMechanical engineering

The invention discloses a door and window profile which can be cut and used freely comprising a cleading; the cleading is provided with an inner cavity and / or an element rest. The invention is characterized in that the inner cavity and / or an element rest extend horizontally along the cleading. The cleading of the door and window profile can undergo standardized production with site cut and installation, thereby improving working efficiency and shortening decoration period.

Owner:程礼中

Precast concrete wallboard and preparation method thereof

ActiveCN101831985BLow costGuarantee the construction qualityConstruction materialForms/shuttering/falseworksReinforced concreteArchitectural engineering

Owner:华筑(辽宁)建筑工程设计有限公司

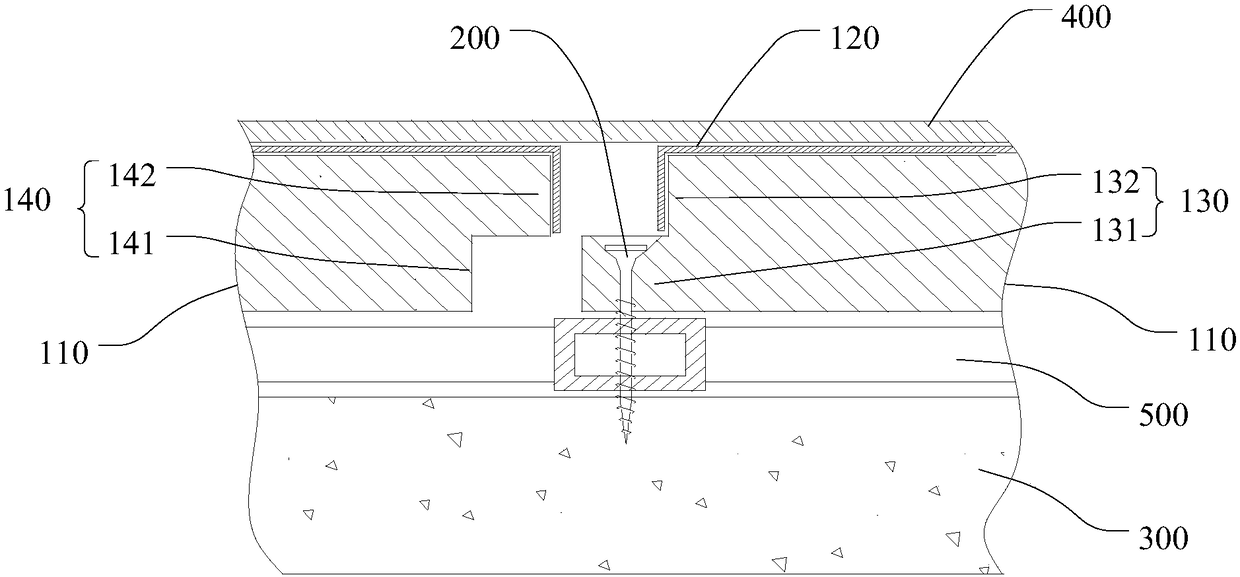

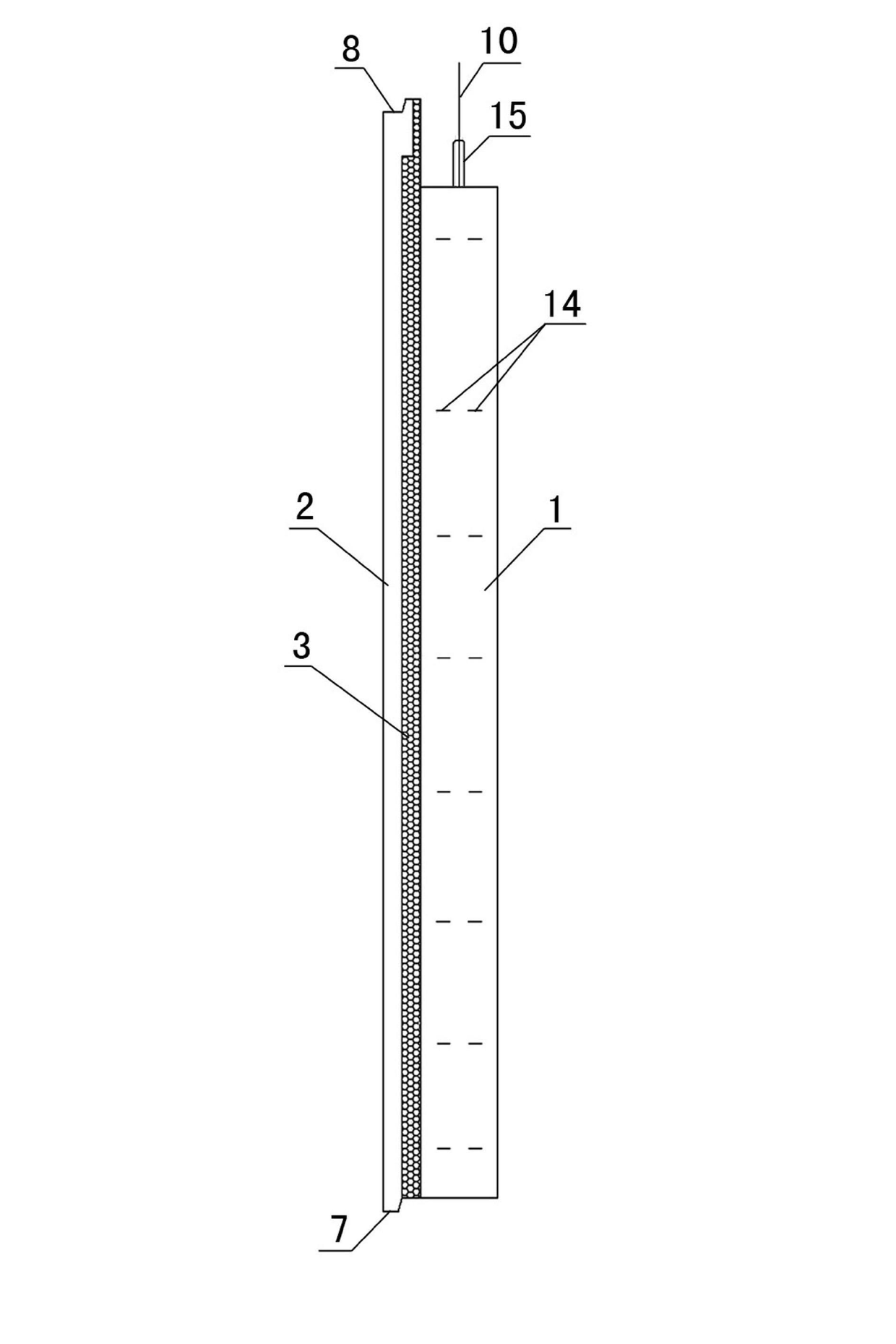

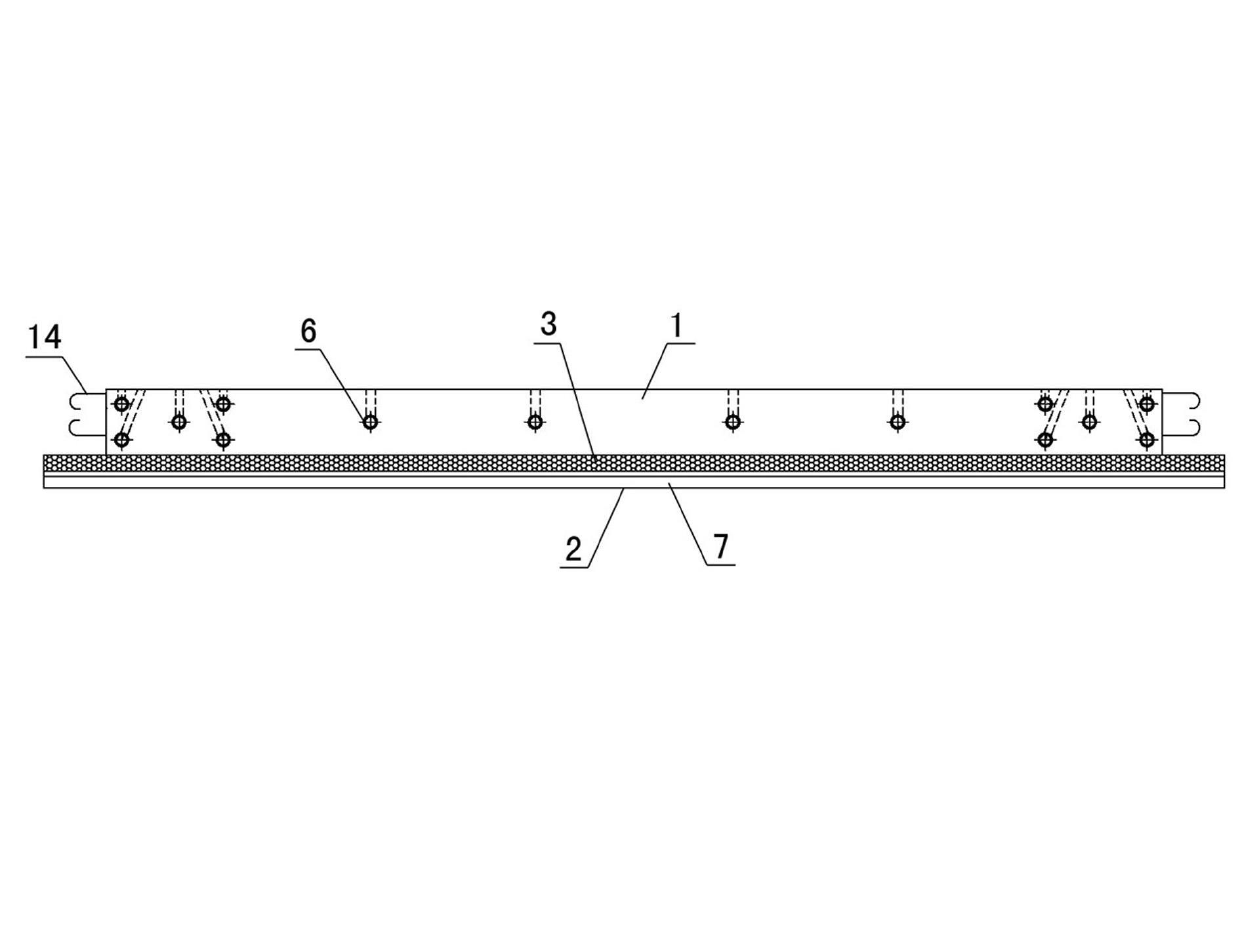

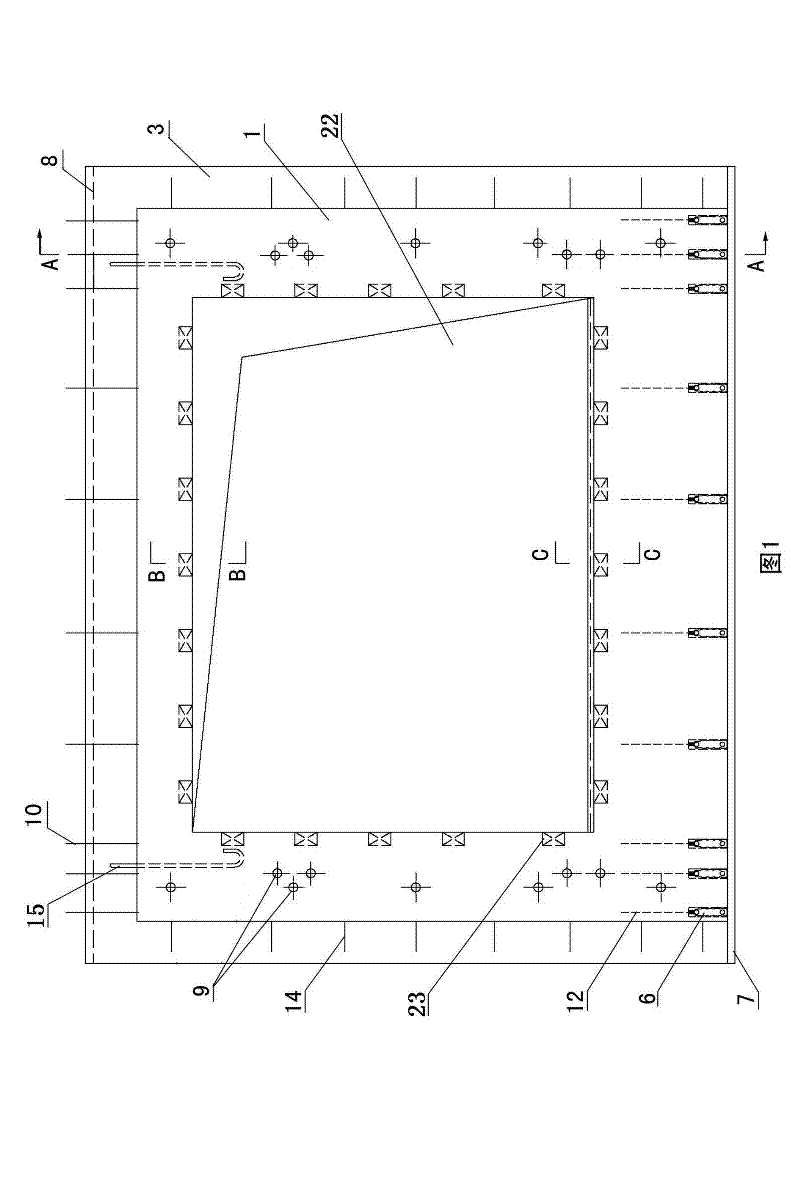

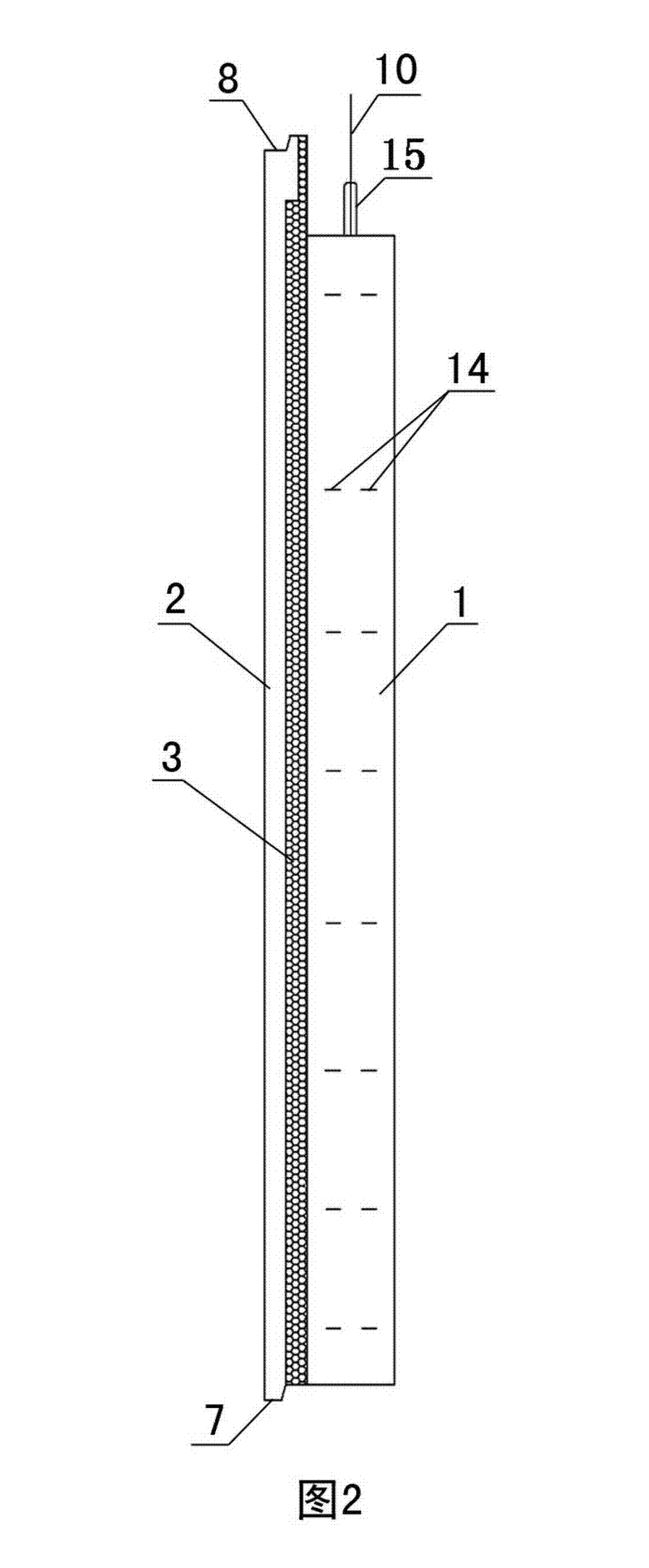

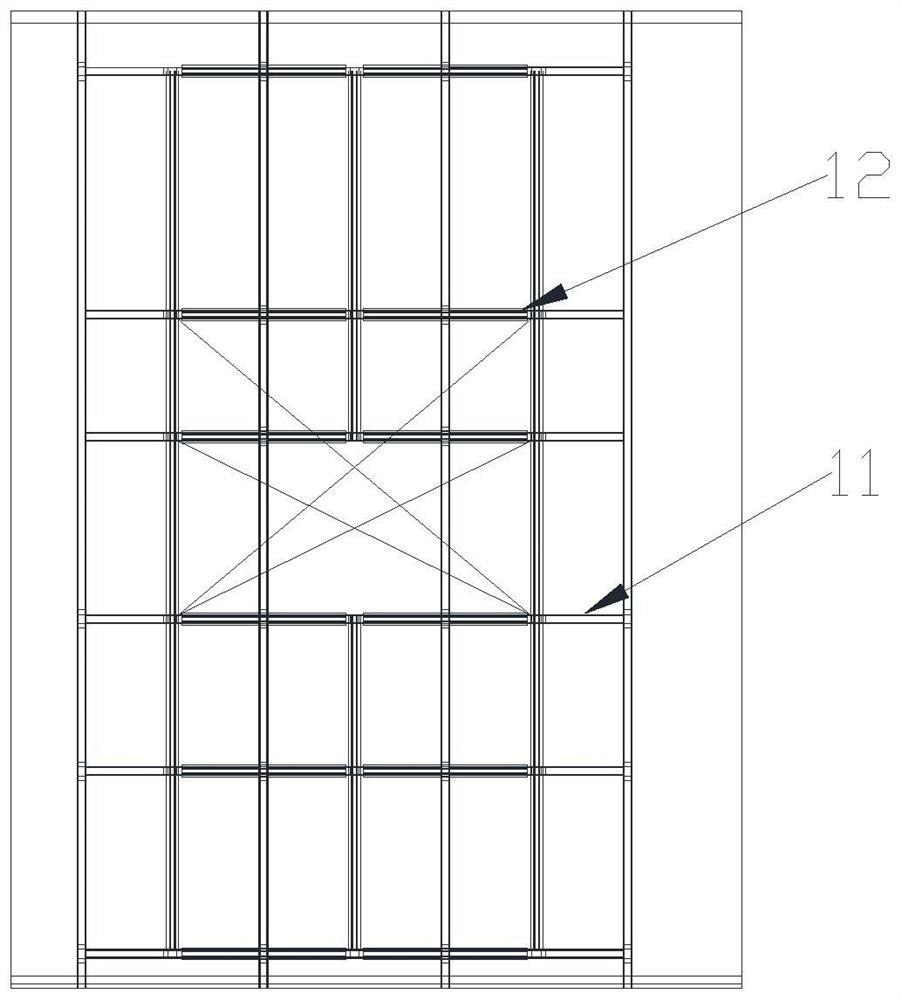

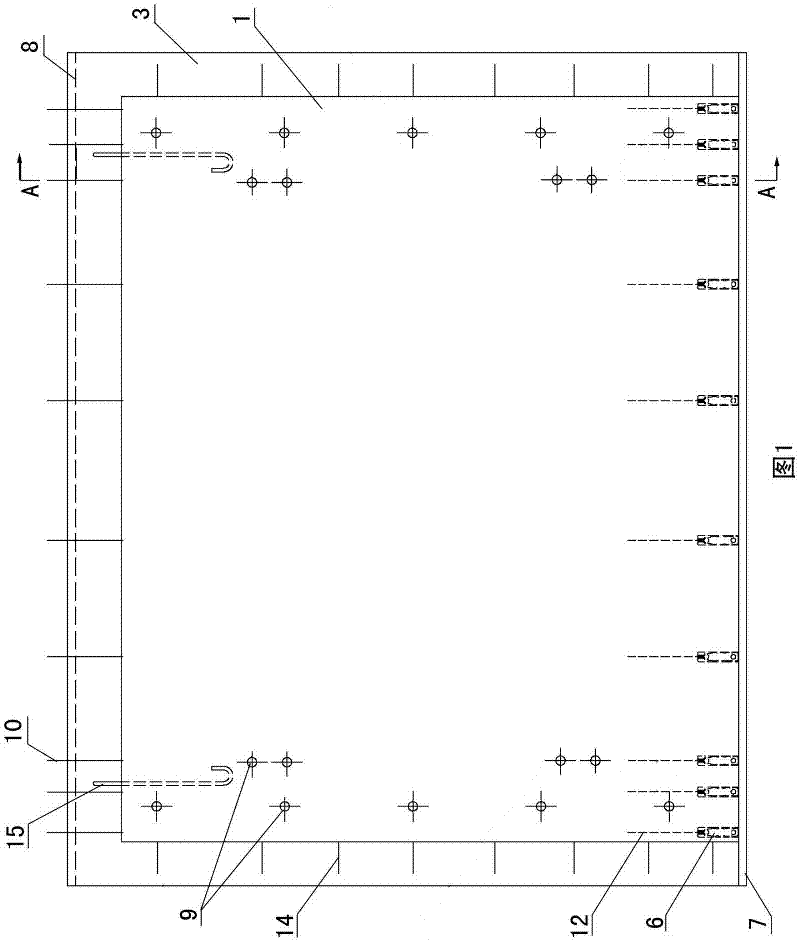

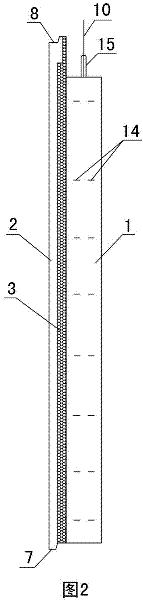

Prefabricated assembly type decoration surface of house inner wall surface

ActiveCN113719052AShorten the renovation periodReduce qualityCovering/liningsStructural engineeringMechanical engineering

The invention relates to a prefabricated assembly type decoration surface of a house inner wall surface. The prefabricated assembly type decoration surface comprises a wall, a skirting line, a supporting bottom strip and a plurality of decoration plates spliced together along the horizontal direction, wherein the adjacent decoration plates are connected together through a sealing strip, the outer side edge of the decoration plate positioned at the outermost edge is connected with the wall through an edge covering strip, the lower end of the supporting bottom strip is supported on the ground, the supporting bottom strip comprises a supporting bottom strip back plate, a supporting strip connected to the front side of the supporting bottom strip back plate and a supporting bottom strip shielding strip connected to the upper side face of the front end of the supporting strip, the supporting bottom strip back plate, the supporting strip and the supporting bottom strip shielding strip define a decorative plate supporting groove, the lower end of the decorative plate is arranged in the decorative plate supporting groove in a penetrating mode and supported on the supporting strip, the skirting line is connected to the lower portion of the supporting strip, and the supporting bottom strip portion back plate is connected with the wall. According to the prefabricated assembly type decoration surface, the problem of poor environmental protection property caused by decoration through a coating and wall cloth in the prior art is solved.

Owner:浙江雅迪乐家居有限公司

Lamp module for integrated ceiling and integrated ceiling

The invention discloses a lamp module for an integrated ceiling. The lamp module comprises hoisting pieces, a lamp shell, connecting components as well as first keel pieces and second keel pieces which are perpendicular to each other, wherein sliding rail structures are arranged at the tops of the first keel pieces and the top of the second keel pieces, a clamping structure capable of moving and / or being fixed on the corresponding sliding rail structure is arranged at one end of each hoisting piece, the connecting components are connected with the sliding rail structures of the first keel pieces and the sliding rail structures of the second keel pieces, each first keel piece comprises a first keel and a second keel, each second keel piece comprises a third keel and a fourth keel, and the first keels, the second keels, the third keels and the fourth keels define an installation space used for fixing the lamp shell. The invention further discloses the integrated ceiling connected with the lamp module for the integrated ceiling. The first keel pieces and the second keel pieces are connected through the connecting components, so that the lamp module used for hanging a lamp is formed, the first keel pieces and the second keel pieces are also connected with frame keel pieces through connecting components, connection is flexible, and disassembly and assembly are convenient.

Owner:浙江鼎美智装股份有限公司

Installation structure and installation method of a ceiling board

The invention discloses an installation structure and an installation method of a ceiling board, relating to the technical field of building decoration, comprising a pair of L-shaped members composed of a vertical board and a horizontal board, and a pair of L-shaped members fixed in a room opposite to each other. The upper part of the opposite side wall and the outer wall of the vertical plate of a pair of L-shaped members are respectively attached to the corresponding side wall, and also includes the ceiling board and a few-shaped keel, and the bottom edge of the two sides of the several-shaped keel and the ceiling board The top surface of the keel is fixedly connected, and the two-shaped keel is vertically arranged with a pair of L-shaped members. Both ends of the several-shaped keel are provided with C-shaped stainless steel sheets and wooden blocks. The C-shaped stainless steel sheet is fixedly connected, and the C-shaped stainless steel sheet can slide outward along the horizontal direction on the side wall of the several-shaped keel and make the bottom surface of the wooden block supported by the top surface of the horizontal plate of the corresponding L-shaped member. The installation structure of the present invention is simple, and the installed speed block can shorten the construction period of decoration.

Owner:ZHEJIANG YASHA DECORATION

Assembly method of assembly type medical unit

ActiveCN114837321AQuick assemblyQuick releaseCovering/liningsWallsMedical unitMechanical engineering

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

Injection molding manufacturing method of upvc wall decoration board

ActiveCN104859088BGuaranteed structural strengthGuaranteed dimensional accuracyCoatingsHot runnerEngineering

The invention discloses an injection molding manufacturing method of a UPVC wall decorative plate. The method comprises the following steps of opening a mold, arranging a film in the mold, wherein one surface of the film is an appearance display surface and the other surface of the film is a UPVC plastic layer, making the appearance display surface of the film contact with a molding surface of the mold and the UPVC plastic layer of the film face to the mold cavity space, positioning the sticky film in the mold by a film positioning device, closing the mold, injecting a molten UPVC material into the mold by a hot runner system through multiple branched channels and multiple plastic inlet points, keeping a closing state of the mold for a certain time until the molten UPVC material and the UPVC plastic layer are cured to form an integral wall decorative plate, opening the mold, and pushing the molded wall decorative plate out of the mold by a demolding device. The injection molding manufacturing method realizes large-scale and low-cost manufacture of the wall decorative plate from the UPVC material. The injection molding manufacturing method reduces a decorative material cost, shortens a finishing construction period, reduces a labor cost and realizes nontoxic gas discharge and environmental protection effects.

Owner:BEIJING LONGFA ARCHITECTURAL ORNAMENT ENGCO

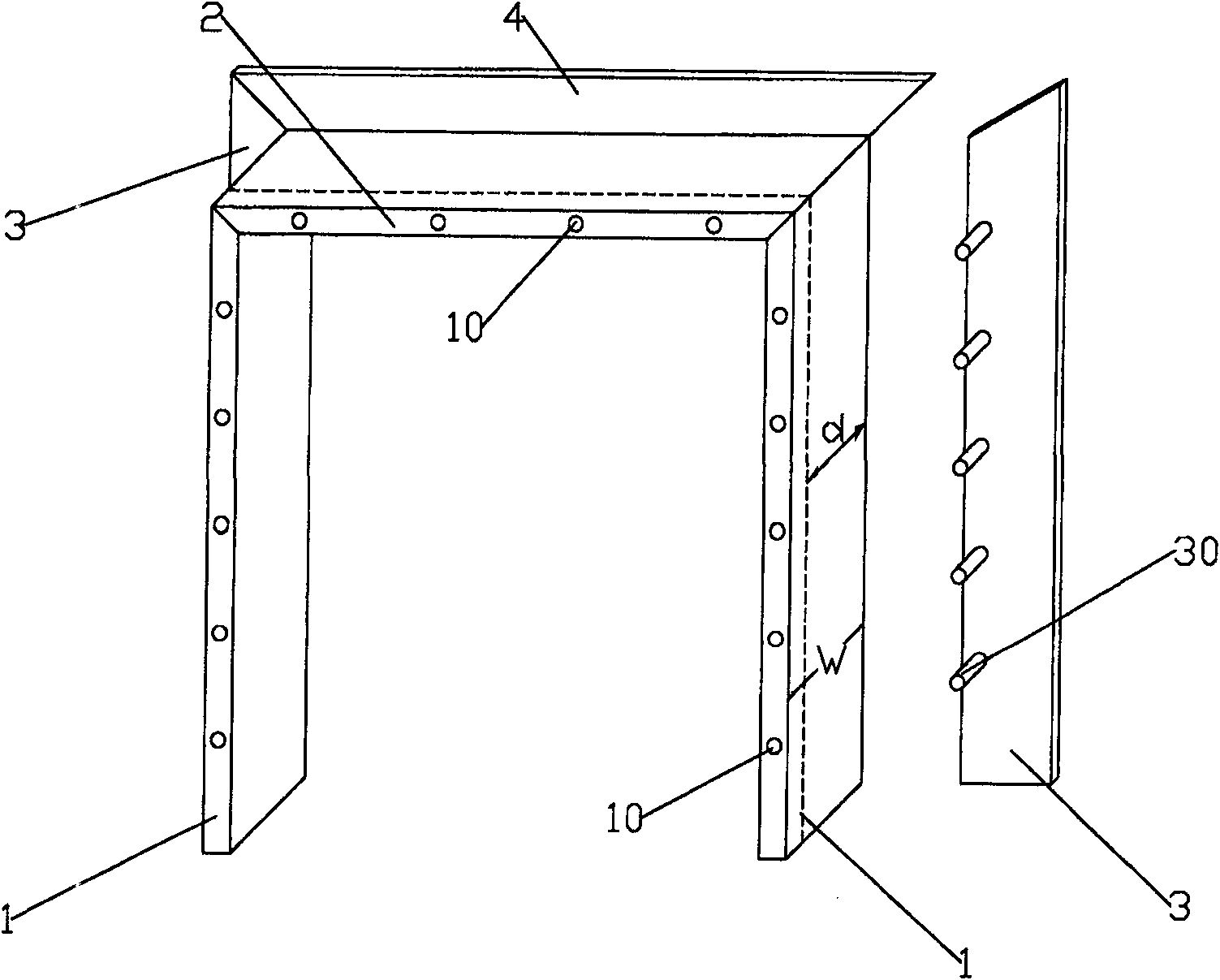

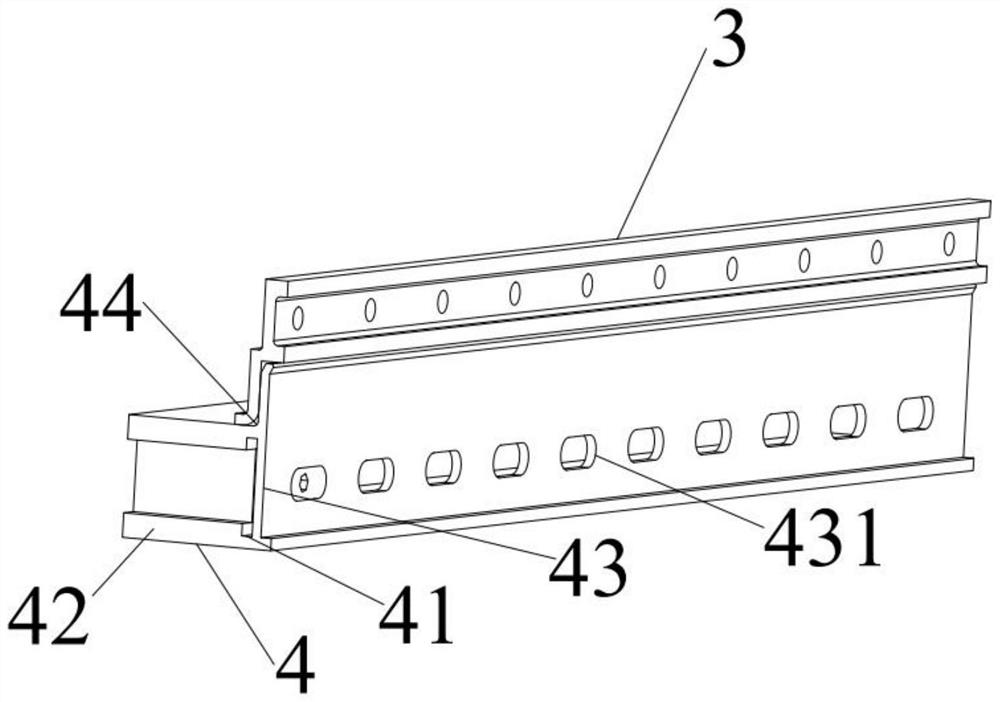

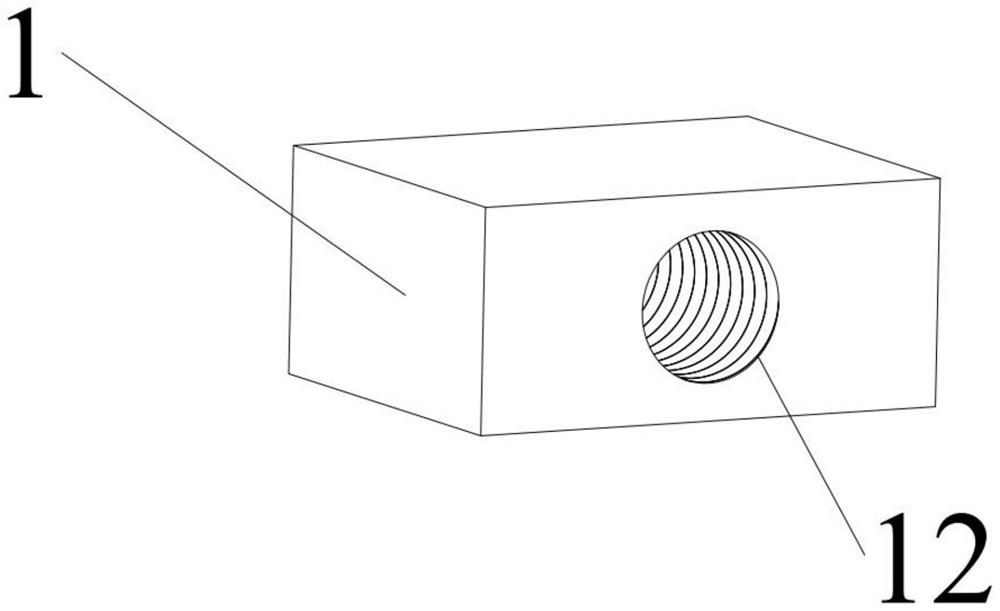

Light steel keel for assembled door pocket

The present invention is a light steel keel used for an assembled door cover. There are several assembly holes for fixing the base plate on the upper and lower sides of the front of the light steel keel, and several operation holes are opened on the upper surface of the light steel keel; The back of the light steel keel is provided with a number of fixing parts for fastening the keel and the wall A. The shape of the keel is like or like, like, like, like. Advantages: No special tools are required for installation, the whole installation process is simple and convenient, and the door cover and the wall are fixed reliably; because the shape of the light steel keel is round, the protruding steel part and the groove on the back of the wooden molding are tightly matched, stable , strong; simplified production process, convenient operation, improved work efficiency, low production cost; the frame made of light steel, the door pocket has high horizontal and vertical degrees, flat and firm, and is not easy to deform. The door cover is easy to assemble, saves labor and materials, saves a lot of wood, and realizes industrialized mass production.

Owner:JIANGSU YINMAO HLDG GROUP

Wall protection dry-hanging structure system capable of leveling wall surface

PendingCN112554491AEasy to adjustIncreased cost of capitalCovering/liningsArchitectural engineeringCapital cost

The invention relates to the technical field of decoration wall surface assembling hardware, in particular to a wall protection dry-hanging structure system capable of leveling a wall surface. The wall protection dry-hanging structure system comprises an adjusting base, an adjusting bolt, a wall protection hanging piece and a wall protection hanging strip, the adjusting base is fixedly mounted inthe wall surface, and the two ends of the adjusting bolt are matched with the adjusting base and the wall protection hanging strip; and one end of the wall protection hanging piece is matched with thewall protection hanging strip, and the other end of the wall protection hanging piece is fixedly connected with a veneer so as to fasten the wall protection hanging strip and the veneer. The wall protection dry-hanging structure system has the beneficial effects that a traditional woodworking base layer beating mode can be effectively avoided, the increase of capital cost and time cost is avoided, the structure is simple, mounting and adjusting are easy, using is convenient and fast, the decoration period is shortened advantageously, and the wall protection dry-hanging structure system has acertain market popularization prospect.

Owner:玛格家居股份有限公司

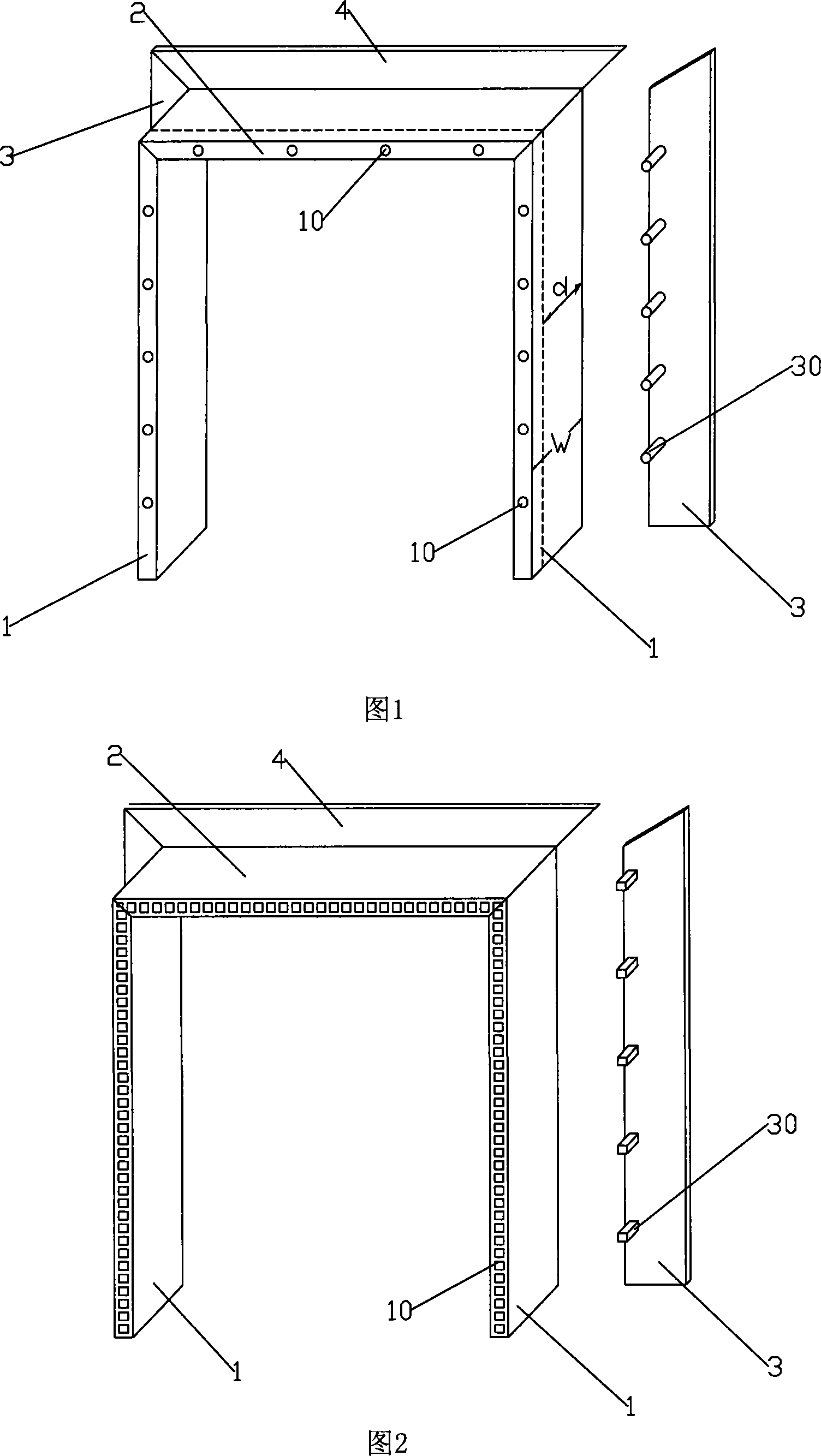

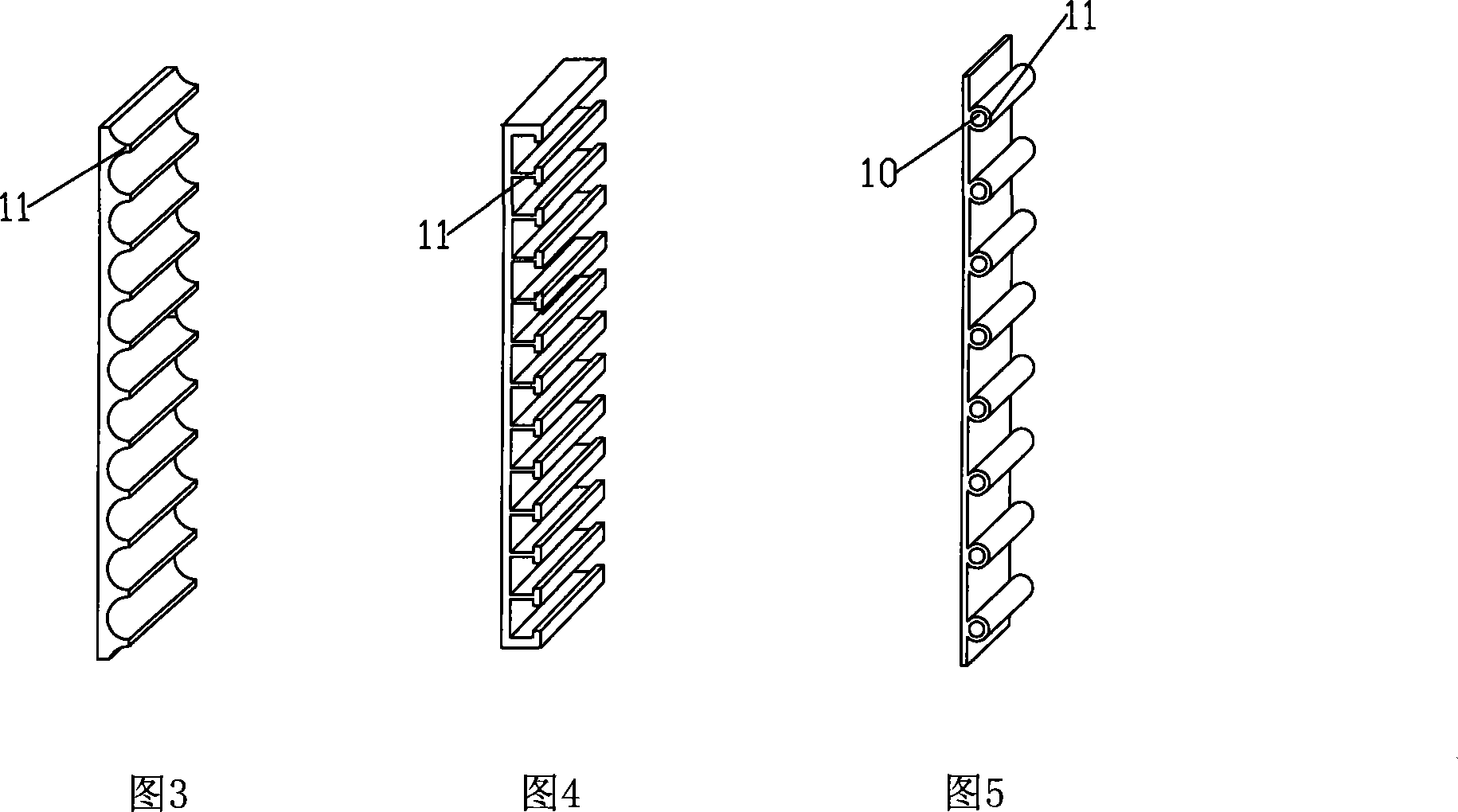

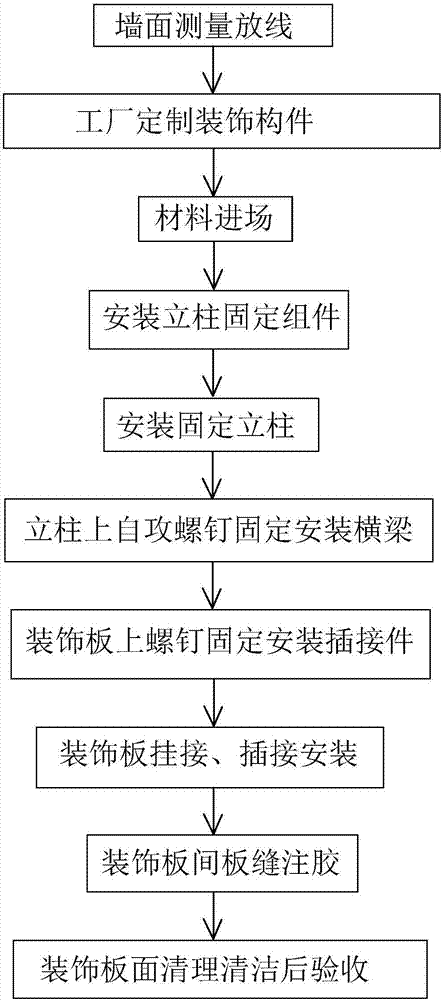

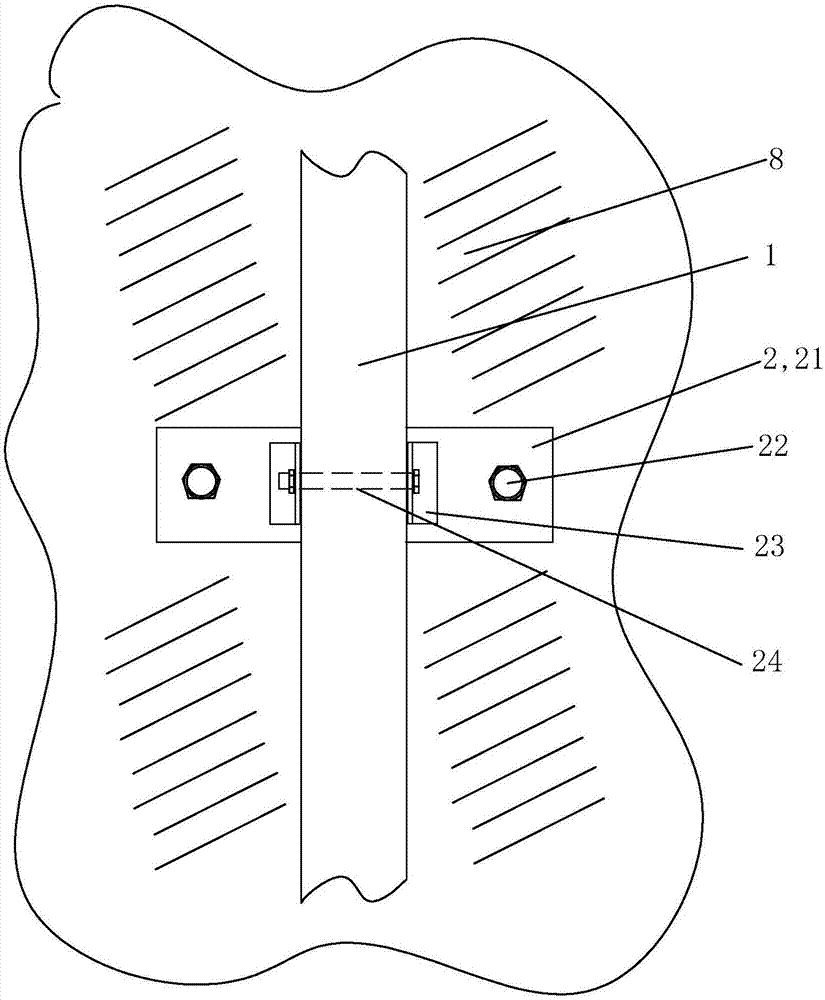

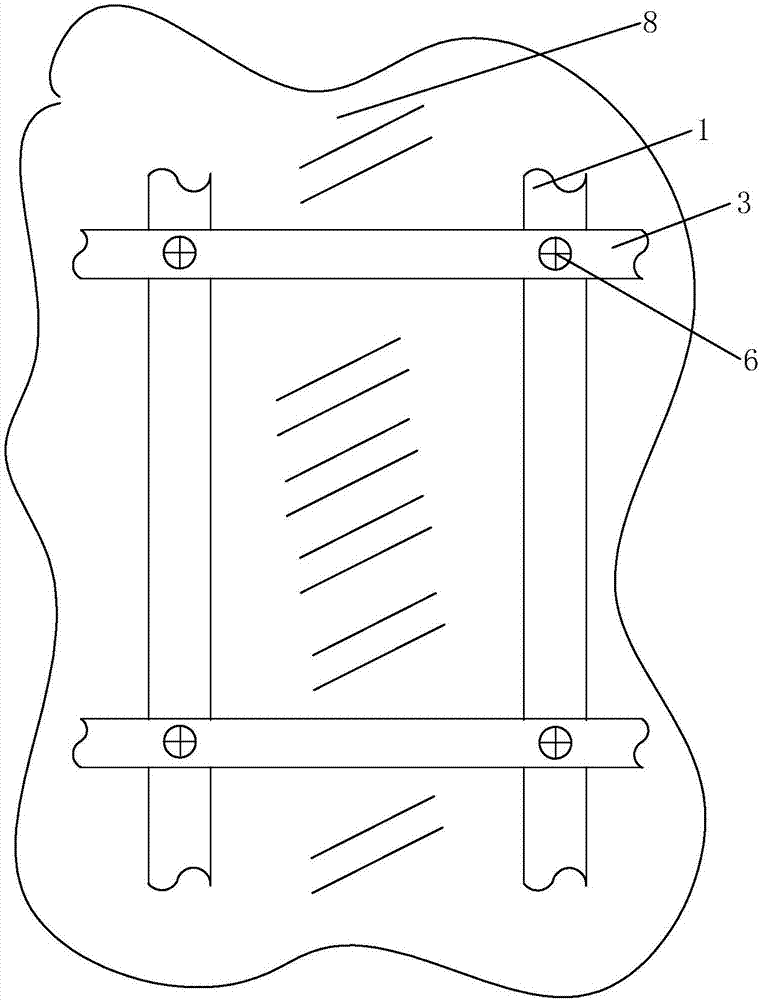

Cutting-free inserting-connection-type mounting construction method of wall surface decoration boards

ActiveCN107989381AHas radiationDirt-resistantBuilding material handlingConnection typeSurface measurement

The invention provides a cutting-free inserting-connection-type mounting construction method of wall surface decoration boards. The cutting-free inserting-connection-type mounting construction methodmainly adopts vertical columns, vertical column mounting assemblies, cross beams, the decoration boards, Z-shaped inserting-connection pieces, tapping screws and screws to implement, the cutting-freeinserting-connection-type mounting construction method comprises the steps that (1) wall surface measurement and paying off are conducted, and a mounting construction scheme is determined; (2) components required by decoration is custom-made at a factory; (3) materials are transported to a site; (4) vertical column fixing assemblies are mounted; (5) the vertical columns are mounted and fixed; (6)the cross beams are mounted and fixed; (7) the Z-shaped inserting-connection pieces are fixedly arranged on the decoration boards; (8) the decoration boards are mounted in inserted-connection and hung-connection modes; (9) glue are injected into board seams; and (10) clearing and cleaning of the decoration board surfaces and acceptance are conducted. According to the cutting-free inserting-connection-type mounting construction method of the wall surface decoration boards, the decoration boards are mounted by utilizing the inserting-connection pieces, site cutting-free operation is achieved, noise and dust pollution are less, construction is simple, convenient and fast, cost performance is high, and the used materials during secondary decoration can be recycled.

Owner:CHANGZHOU NO 1 CONSTR GRP

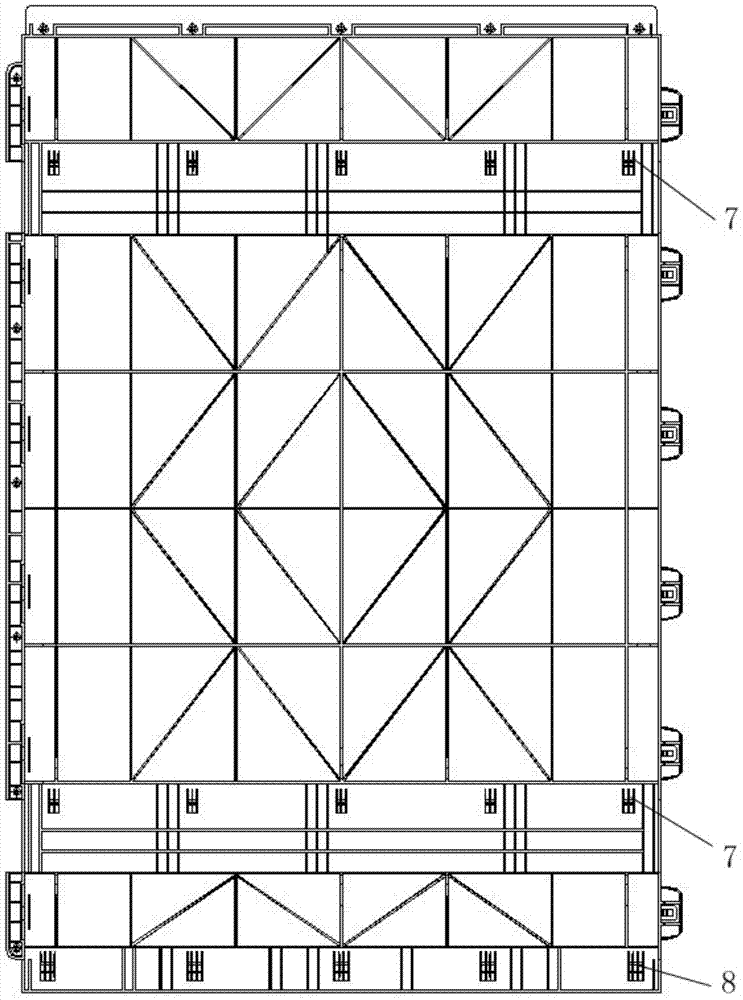

A kind of wall panel manufacturing process

ActiveCN108412119BReduce wasteImprove efficiencyBuilding componentsAdhesive glueMechanical engineering

The invention discloses a wall panel manufacturing process, which is characterized in that it comprises the following steps: A: making a keel component (1); B: fixing a bottom plate (2) on one side of the keel component (1); C: fixing the bottom plate (2) ) on the brush adhesive glue (3); D: pasting a plurality of ceramic tiles (4) on the bottom plate (2). The wall panels manufactured by the wall panel manufacturing process of the present invention have already been pasted with ceramic tiles in the factory workshop. When the house is decorated, only a few wall panel modules need to be transported to the construction site, and the wall panels can be fixedly installed on the wall of the house. , avoid cutting tiles at the construction site, pasting tiles and other processes, improve efficiency, avoid material waste, and reduce costs.

Owner:ZHONGSHAN SALLY SHOWER EQUIP

Assembled integral building and construction method thereof

ActiveCN101818539BGuarantee the construction qualityLow costBuilding componentsFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in theconcrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional constructionmethod, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com